In this interview, AZoM speaks with Beau Preston, Founder of Rainscreen Consulting, about STRONGIRT, an ideal continuous insulation (CI) cladding attachment support system and its applications.

What is STRONGIRT®?

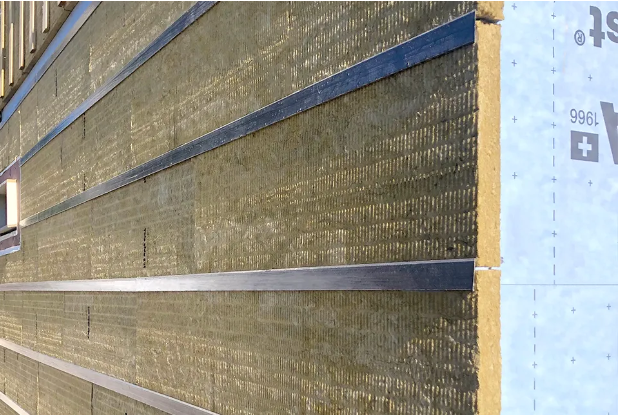

With a few exceptions, continuous insulation (CI) is required in all non-wood framed commercial buildings in the US. STRONGIRT® is a pultruded, fiberglass zee girt, designed to reduce/eliminate the thermal bridge through the continuous insulation layer in a modern wall design.

The “Z” shape of the girt allows it to be fastened to the substrate of the wall over the sheathing and air barrier. This creates a shelf to secure the insulation and provide an outer flange to screw cladding or sub-framing without penetrating the insulation layer with additional, thermal-bridging materials, such as fasteners, galvanized zees and hat channels, or cladding attachment clips.

Image Credit: Strongwell

How did you get involved with STRONGIRT®?

I got involved in the construction industry in 2014 when I helped bring a zee girt to prominence in the CI industry and started knocking down the barriers in markets preventing it from taking hold.

In 2018, I began consulting with companies interested in developing a presence in the US marketplace. By 2019, my company, Rainscreen Consulting (RC), was born. Not long afterward, I was approached by some colleagues to help Strongwell develop STRONGIRT® and bring it to market. This was the perfect opportunity to use all the years of feedback from the field to make STRONGIRT® the most approachable, cost-effective cladding attachment system on the market.

My experience with many CI products and Strongwell’s unsurpassed knowledge/experience in pultrusion has created a very fruitful relationship.

What makes STRONGIRT® different from other girts?

When developing STRONGIRT®, we knew we had to make it simpler than the other girts in the market while making it more readily available.

Installers around the country complained about requirements for using proprietary insulations, parts, and pieces. They wanted to buy their girt from the supplier and procure the rest of the wall components locally from their trusted distributors. They were also concerned about the corrosion they were seeing in metal components at drill holes and riveted areas.

They needed a product that could be used near water, in cold/hot environments, and they wanted to remove the need to constantly seek special approvals/engineering. Most importantly, they needed a cost effective system. STRONGIRT® meets all of these needs.

Partnering with Strongwell to bring STRONGIRT® to market has been the best choice. Strongwell is the recognized world leader in pultruded composites and has the R&D and technical resources to make the best pultruded girt that money can buy.

Image Credit: Strongwell

Why would an architect choose to specify STRONGIRT® with all other products available on the market?

Many architects have appreciated what STRONGIRT® brings to the market.

First and foremost, STRONGIRT® accomplishes everything it needs to with the least amount of labor, cost, detailing, and training. Considering that, before the market fully understood thermal bridging in walls, galvanized zees were used and generally accepted by the design community and the installation crews.

STRONGIRT® has been thoroughly tested by simulating the wind and cladding loads simultaneously by DrJ Engineering. Upon successfully testing the NFPA 285 fire testing, DrJ Engineering certified the girts and published a technical evaluation report that structural engineers can use in their designs. Simply replacing the galvanized zees with a pultruded fiberglass zee answers their needs at the core.

Some other systems on the market require proprietary insulation that is costly to fabricate and ship around the country. Others force installers to blind fasten very long fasteners through all the wall layers, hoping to hit a significant structural member underneath. The install community does not appreciate this level of required “perfection”. STRONGIRT® does not require proprietary insulation, and fastening it is easy and efficient.

Besides the simplicity of STRONGIRT®, the competitive price of the material and the low installation cost drastically reduces the chances that it gets “Value Engineered” (“VE’d”) from a job in lieu of another system. This also reduces the chance that a project becomes non-code-compliant or needs to be redrawn.

Finally, STRONGIRT® improves on the other systems already on the market. Down to its dark gray color, STRONGIRT® is meeting the demands of the same people who would be specifying it. Speaking of color, STRONGIRT® is dark gray, so it does not appear in open joint rain-screen systems.

Other competitive systems on the market range are neon green, purple, orange, and shiny galvanized steel. Most of those are simply marketing ploys and have no actual benefit to anyone other than that company’s marketing departments.

STRONGIRT® also has the best fire performance versus other pultruded girts. With Strongwell’s decades of pultrusion experience, we knew they would not cut corners regarding safety. STRONGIRT® self-extinguishes per UL-94 standards.

Other areas that STRONGIRT® exceeds competitive capabilities are:

- The Ultra line of STRONGIRT® can retain a horizontal orientation beyond 4” in depth (currently as deep as 8”).

- STRONGIRT® has a better pullout strength with #14 tek screws than 18 ga steel or other fiberglass girts.

- STRONGIRT® is available in custom lengths, colors, and drainage options.

- STRONGIRT® does not need to terminate on a stud and can cantilever between two studs, making it less wasteful than other systems.

Image Credit: Strongwell

What is next for Rainscreen Consulting and STRONGIRT®?

Rainscreen Consulting is proud of the market’s adoption of STRONGIRT®. From airports to universities, to corporate headquarters, STRONGIRT® has been generally accepted as a top-tier solution to code-compliant continuous insulation and cladding attachment support.

Moving forward, RC will be introducing STRONGIRT® to other manufacturers looking for solutions to improve their systems in the wall. From tilt-up concrete to NFPA 285 tests, STRONGIRT® could make large differences in other products’ viability in the market.

While our reps continue to support our design and install communities, our management teams will continue to seek ways to allow Strongwell and STRONGIRT® to better serve the community.

Rainscreen Consulting, with its various ventures, will “cross-pollinate” the ideology of STRONGIRT®, where relevant, in its rain-screen cladding divisions, and look for ways to constantly improve the STRONGIRT® offering to the market.

About Beau Preston

Beau Preston has always been fascinated with entrepreneurs. From the time he waited tables during high school through his career as a commercial banker, he has been surrounded by individuals running their own businesses and has taken every opportunity to learn from them. From that early age, Beau has owned businesses that include tutoring, computer building, web design, and real estate investment. While those businesses came and went, they helped forge him into a business owner unafraid to try and unafraid to fail.

Today, Beau is living his dream, building three vertically integrated businesses. Rainscreen Consulting, CarolinaREP, and Omnis Panels are each successful in their own regard, but have a significant synergy between them. Having recognized that the most successful entrepreneurs are surrounded by the most successful people, he built these companies with a strong foundation of talented team members, who allow him to continue to look for that next opportunity.

This information has been sourced, reviewed and adapted from materials provided by Strongwell Corporation.

For more information on this source, please visit Strongwell Corporation.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.