With the popularity of fitness trackers, smartwatches, and other health monitoring and entertainment gadgets, wearable technologies have soared in recent years. The need for innovative materials that are accurate data collectors and transmitters, lightweight, tough, and comfortable to wear for extended periods of time is growing along with the demand for wearable technology. It takes careful consideration of the materials used in their construction to achieve this harmony between form and function.

Image Credit: Stable Micro Systems Ltd

Researchers need to assess the flexibility, firmness, and other physical features of the materials that make up wearable devices and this is made easily possible thanks to the use of a TA.XTplusC/TA.HDplusC Texture Analyser, which has become a powerful tool for creating and developing novel materials for wearable technologies. A detailed understanding of a material's mechanical characteristics, such as its texture, firmness, elasticity, and durability, is necessary for the creation of new materials for wearable technology as wearability, comfort, and lifetime are impacted by these characteristics.

Examples of How Materials Can Be Measured Using a Texture Analyser:

Using a Texture Analyser, the deformation and mechanical characteristics of a material under particular loading circumstances at chosen locations on the test sample can be measured which offers a scientific and quantitative way for characterising mechanical qualities. The forces and deformations that come from compressing or stretching the material in a range of different ways are recorded. The behaviour of materials under various situations, such as temperature, humidity, pressure, and wear, can also be understood using this technical method. There are a number of devices that are used on the Texture Analyser to support or test the sample in a particular way according to the property that is being measured. Below presents a few examples:

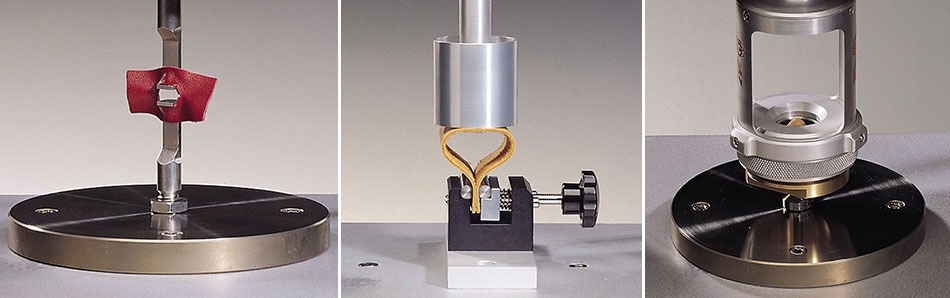

Texture Analyser measuring Slot Tear, Loop compression and material burst strength. Image Credit: Stable Micro Systems Ltd

Texture Analyser measuring Tensile strength, ‘Trouser’ tear and T-peel properties. Image Credit: Stable Micro Systems Ltd

How Does a Texture Analyser Benefit the Development of New Materials for Wearable Technologies?

- Assessing fabric comfort: A key factor in determining the comfort of fabrics is their ability to stretch and recover. This is critical to ensuring a comfortable and secure fit. Researchers can use mechanical testing to measure properties such as softness, flexibility, and elasticity, helping to identify the optimal level of each that will provide the ideal fit without restricting movement or causing discomfort.

- Optimizing adhesive properties: Wearable technologies rely on adhesives to accurately measure physiological signals. By using a Texture Analyser, researchers can optimize adhesive properties, ensuring that they are both durable and flexible enough to adhere to a variety of surfaces.

- Innovating 3D printing materials: The rise of 3D printing has led to a demand for materials that are both lightweight and flexible yet strong enough to meet the demands of wearable technology. Mechanical testing with a Texture Analyser can be used to develop new materials for 3D printing that meet these criteria, allowing for the production of wearable devices that are both functional and comfortable.

- Evaluating component durability: Wearable devices must be able to withstand repeated use and exposure to environmental factors. A Texture Analyser can help researchers identify materials that are resistant to wear and tear, allowing for the creation of wearable devices that are both durable and reliable. By measuring the physical properties of materials, researchers can find the ideal combination of materials to create wearable devices that can withstand the demands of everyday use.

Pioneers Already Using a Texture Analyser for Wearable Device Development

Whilst commercial companies do not reveal how they are already harnessing the measurement capabilities of their Texture Analyser to get ahead in this fast-paced development environment, we can highlight some recently published papers from the academic world that use the Texture Analyser.

Highly Stretchable, Self-Repairable, and Super-Adhesive Multifunctional Ionogel for a Flexible Wearable Sensor - Researchers from Beijing Technology and Business University used their TA.XTplus Texture Analyser to measure the strength and elasticity of the ionogel and envision using the material in sensors that could be worn on the skin and monitor vital signs like heart rate and blood pressure.

Humidity‐Resistant, Broad‐Range Pressure Sensors for Garment‐Integrated Health, Motion, and Grip Strength Monitoring in Natural Environments - University of Massachusetts researchers have created a humidity-resistant pressure sensor device that may be incorporated into clothing to track activity, grip strength, and general wellness. The technique employs flexible, elastic silicones and moisture-resistant graphene-based electrodes that are used to evaluate fabric panels using their Texture Analyser. The fingertips have sensors that may be set to track muscle activity and grip force. Athletes, members of the military, people with physical disabilities, and people who suffer from long-term medical ailments may find use for the device, which can also detect changes in temperature and humidity.

All-Starch-Based Hydrogel for Flexible Electronics: Strain-Sensitive Batteries and Self-Powered Sensors - A flexible hydrogel that was created by Guangdong University researchers may help to advance wearable technology. The scientists developed a hydrogel with excellent tensile strength and strain sensitivity that may be used as a flexible battery or as a strain sensor by mixing starch with a sodium polyacrylate solution. They assessed the hydrogel's mechanical characteristics using their Texture Analyser and discovered that it had good shape retention even when stretched. The hydrogel is anticipated to be employed in garments, medicinal applications, and wearable technology like smartwatches.

Enhanced skin adhesive property of electrospun α-cyclodextrin/nonanyl group-modified poly (vinyl alcohol) inclusion complex fiber sheet - An approach to improve the adhesive characteristics of electrospun alpha-cyclodextrin/nonanyl group-modified poly (vinyl alcohol) inclusion complex fibre sheets has been devised by scientists at the National Institute for Materials Science in Japan. The scientists evaluated the material's stickiness using their Texture Analyzer and found that it might be useful for medical adhesive products or wound healing. The study illustrates the revolutionary potential of electrospinning for material design and benefits of employing Texture Analysers in materials science.

Self‐Healing Photochromic Elastomer Composites for Wearable UV‐Sensors - A self-healing photochromic elastomer composite material has been created by Thai researchers at the Vidyasirimedhi Institute of Science and Technology (VISTEC) that can be utilised to make wearable UV sensors. They measured the material's tensile strength and elongation using their Texture Analyser before coating it with a thin film to enhance its photochromic characteristics. The substance changes colour when exposed to UV light, making it possible to measure the UV radiation level. The material is perfect for use in wearable devices because of its ability to repair any damage brought on by repeated use.

Zinc-ion Engineered Plant-based Multifunctional Hydrogels for Flexible Wearable Strain Sensors, Bio-electrodes and Zinc-ion Hybrid Capacitors - Using a Texture Analyser, scientists from Qilu University of Technology have developed plant-based hydrogels for wearable strain sensors, bio-electrodes, and hybrid zinc-ion capacitors. The hydrogels were designed to offer flexibility and good conductivity and were created from bacterial and plant cellulose. The group assessed the hydrogels' compressibility and tensile strength using their Texture Analyser. According to the research, these plant-based hydrogels offer a lot of promise for usage in a variety of applications, such as energy storage and medicinal devices.To discover hundreds more published paper using the Texture Analyser for wearable sensor research, click here:

See other examples of using a Texture Analyser for materials testing

See how other industry leaders use texture analysis for innovative materials testing to get ahead of their competition

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.