At JEC World, AZoMaterials met with Fraunhofer ICT to discuss their presence at the show and the new technologies they were presenting.

Please can you introduce yourself and your professional background?

My name is Rudolf Emmerich, and I work at Fraunhofer ICT. Originally I studied physics, but now I'm working in the field of microwave and plasma technology, for example, composite manufacturing. Together with partners, we developed a sustainable aircraft seating structure based on composite.

Fraunhofer has divisions fostering innovation across many scientific and industrial sectors. Could you please tell us what the focus of Fraunhofer ICT is in particular?

Fraunhofer Society has headquarters in Munich with around 28,000 employees. Fraunhofer ICT is one part of this society. We have 580 employees in six departments. Two departments deal with energetic materials and testing of energetic materials; one department deals with electrochemistry, and one with sustainability and recycling technologies. Then, our department deals with polymer engineering with a strong focus on composites, foam technology, and packaging, and we have new drive systems which deal with new combustion motors, for example, to burn eFuels or ammonia.

What kind of research and development capacities does Fraunhofer ICT have?

As a Fraunhofer Institute, we are strongly linked to industry. In our department, we cooperate with aircraft and automobile manufacturer and their suppliers, the chemical industry, and the entire plastics and packaging industry, to name a few. Mostly, we develop processes up to a demonstrator level just to show visibility and show the market the potential. Some selected successful developments we bring to a pilot level.

After the pilot level, the development is taken up for industry by industrial partners who will have an interest in selling the product.

What are some of the projects that your division is currently involved with?

Currently, we are working on composite and drive technologies for electric aircraft, the development of a sustainable pultrusion process, mono-material sandwich parts, e.g., PET-fibers n a PET matrix, and lightweight parts. I think the most amazing development topic is that we are making nanoporous adhesion layers with a plasma polymerization process. With this adhesion layer, it's possible to reduce all of these cleaners, primers, and adhesives, and therefore we reduce the carbon footprint of joining by about 90%. We get really strong adhesion, and we only use some silicon-based material.

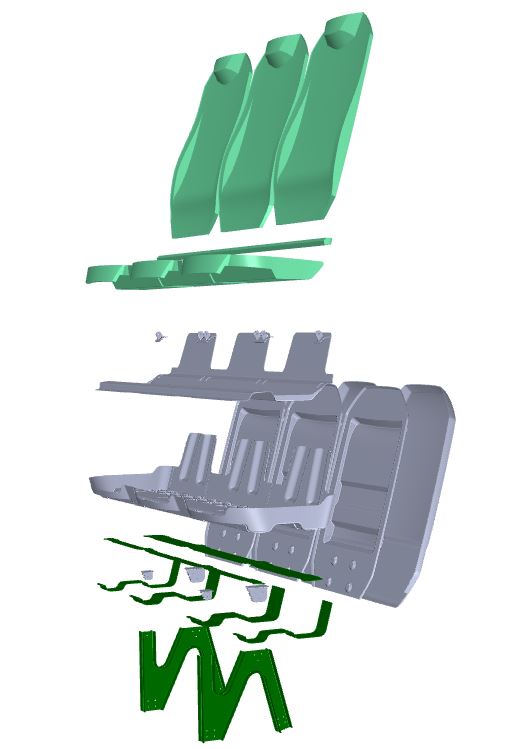

Schematic drawing of the sustainable hybrid seating structure. Image Credit: Fraunhofer ICT

We have used this in hybrid seating structures, and we are looking for aircraft and seat production partners.

Why is it important for Fraunhofer ICT to engage with JEC World – The Leading International Composites Trade Show?

I think this is the most important trade fair for composites. It’s a must for Fraunhofer, and anyone who deals with composites, to come here and show your new products on your new developments. Also, networking is very important. You can see new developments, talk to the experts, and obtain a full overview.

Why should people care about advances in composite materials?

Composite offers many advantages compared to conventional materials. I think the major point is that composites reduce weight and therefore reduce the carbon footprint of parts. In electric vehicles, the battery is heavy, and the range distance is also limited, and therefore you have to reduce the weight to increase the range distance range and efficiency. And composites are one of the most effective ways to do that. Furthermore, they have higher impact strength, damage tolerance, and better corrosion properties.

Were there any products or developments in particular you hoped visitors would engage with at JEC World?

The hybrid aircraft seat is one of the examples where sustainability is the starting point to simplify the recycling process. Therefore, we use only polyurethane because polyurethane exists as a solid material, foam, and adhesive. The separation of individual materials is then not necessary, and the seat can be recycled in one step.

As manufacturing processes for the parts, we select three processes suitable for large-scale production: a sheet molding process for the outer part where high strength and complex geometries are required, wet compression molding for the inner part, and a sustainable plasma-based adhesion technology for metal inserts. The first life cycle analysis shows a reduction in weight directly reduces fuel consumption, leading to a 20% global reduction of the carbon footprint. In addition, the seat consists of just five different parts, drastically simplifying the assembly and maintenance process. We hoped to get a lot of interest in this from other industrial partners.

About Rudolf Emmerich

Rudolf Emmerich achieved his doctoral degree in physics from the KIT (Karlsruhe, Germany). He has nearly 30 years of experience in microwave and plasma technologies, e.g., for accelerating the curing process of composites and adhesives, adhesion, corrosion, and scratch resistance layers deposited with plasma. Living in the Black Forest in Germany, he enjoys outdoor activities hiking, walking, running and good "Baden" food.

Rudolf Emmerich achieved his doctoral degree in physics from the KIT (Karlsruhe, Germany). He has nearly 30 years of experience in microwave and plasma technologies, e.g., for accelerating the curing process of composites and adhesives, adhesion, corrosion, and scratch resistance layers deposited with plasma. Living in the Black Forest in Germany, he enjoys outdoor activities hiking, walking, running and good "Baden" food.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.