Sponsored by Metrohm AGAug 11 2023Reviewed by Olivia Frost

The adulteration of products within the food industry is a constant concern because it is an easy way to reduce costs.1 However, this presents significant health risks if allergens or other harmful cutting agents are introduced, as well as changes in nutritional values and food quality.

Image Credit: Metrohm USA Inc.

Detecting food adulteration is usually challenging due to substitutes mimicking the physical and chemical characteristics of the original product. The identification of any contaminants both in the raw materials and final products is vital to enable the food industry to guarantee high product quality to its consumers.

This can only be achieved with precise measurements conducted during the manufacturing process.

This article discusses using a 2060 The NIR Analyzer from Metrohm Process Analytics to conduct near-infrared (NIR) spectroscopy for the inline analysis of the presence of potato starch adulterant in a wheat flour manufacturing process.

The 2060 The NIR Analyzer provides rapid, reagent-free, nondestructive analysis of potato starch with a reflectance probe created explicitly for this application. The instrument delivers fast results with no chemical reagents being utilized.

Wheat is one of the major global staple crops, with over 778 million metric tons of wheat produced worldwide in 2021–2022, according to Statista.2 Wheat flour is produced from wheat grains, and is the main ingredient in bread, a global staple food.

Starch is the main component within bread, influencing the shape, crumb consistency, and general flavor. Gelatinization occurs during the baking process between the starch within the flour and the water added to the dough.

Breaking down wheat grains into flour involves multiple steps of preparation that differ depending on the type of flour being produced, such as refined flour and whole wheat flour. Milling is the main process and involves grinding the grains to a flour-like consistency.

Like wheat, potatoes are one of the most widely produced crops in America, Europe, and Asia.3

Potato is a staple food in China because of its chemical properties and nutritional value. For example, it has superior water absorption and aids blood glucose regulation.3

Potato flour and wheat flour are chemically alike (mainly composed of starch), making them a good alternative in certain circumstances.4 It is also challenging to distinguish between wheat and potato flour.

The demand for wheat has always been substantial because of its variations and uses, including flour, durum, and bulgur.

As a result, a lot of fraudulent activity has occurred during the production of wheat flour as other materials, including potato flour, may be mixed with wheat flour to reduce production costs and increase production volumes.

However, mixing wheat and potato flour can be advantageous in some cases. Many people are intolerant to gluten, a major protein in wheat.

As a result, depending on the application, a fast, accurate technique for determining the specific content of both components is required to avoid adulterations, cross-contamination, and ensure the high product quality.

Typically, samples are manually withdrawn from the process during the blending of wheat and potato flour and subsequently analyzed offline in a lab. This delay in the results of the analysis being available to the operator can lead to crucial processing decisions needing to be made without the most up-to-date information.

Near-infrared (NIR) spectroscopy is an analytical method widely utilized in the food and feed industry.5 Unlike traditional wet chemical techniques, NIR spectroscopy does not necessitate chemicals and involves minimal sample preparation, meaning it can be carried out by non-chemists.

This technique is also rapid with results typically being available within one minute.

NIR analyzers allow the real-time spectral data from the process to be compared to a primary method to produce a straightforward and essential model for critical industrial process requirements.

Repeated monitoring at multiple process points helps the early detection of adulteration trends, facilitating timely intervention and avoiding widespread contamination. This helps protect consumers and maintain the food supply chain’s integrity.

Manufacturers can employ a 2060 The NIR Analyzer, as shown in Figure 1, to increase control over flour production and monitor up to five process points with each NIR cabinet.

Figure 1. The 2060 The NIR Analyzer with fiber optic cable. Image Credit: Metrohm USA Inc.

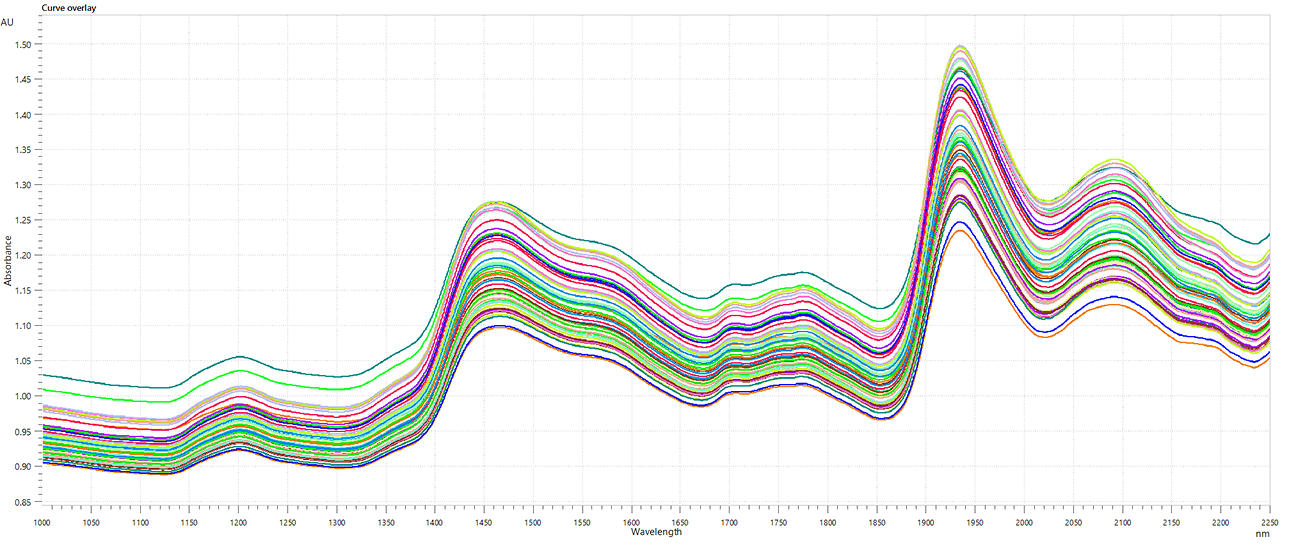

A probe designed for such applications is employed as a spoon with purge vents on the probe tip. After each NIR spectrum is obtained, as shown in Figure 2, an air purge exits via the ports in the probe, clearing the spoon for a new sample.

Figure 2. Raw near-infrared spectra collected during wheat flour blending as measured by the 2060 The NIR Analyzer from Metrohm Process Analytics. Image Credit: Metrohm USA Inc.

Application

The spectra presented in Figure 2 include all concentrations within the range of 0% to 100% for each type of flour (potato and wheat). A spectrum cannot be assigned to a type of flour by visual inspection alone, and advanced mathematics (chemometrics) must be utilized.

The wavelength range utilized is 1100 nm to 2000 nm, corresponding to the region where the compounds of interest give a response. In this case, these are protein, starch, water (moisture), fat, and sugar.

Inline analysis can be carried out using a micro interactance reflectance probe with purge on collection tip directly in a feeder/hopper or in a blender.

Remarks

Both NIRS and primary methods should analyze a suitable range of samples covering the process variability to construct an accurate NIRS model. Correlations are made to process specifications.

The correct NIRS probe must be placed in situ in a way that offers adequate sample contact with the probe tip window. Correct probe design and placement in process equipment are extremely important.

Conclusion

NIR spectroscopy may be employed for the inline detection of wheat flour adulteration to provide a rapid, nondestructive, and reagent-free solution to guarantee product quality and safety in the food industry.

The adulteration of wheat flour with substances such as potato starch can cause health risks and impact nutritional values.

Traditional techniques for the detection of adulteration usually involve manual sampling and offline analysis, which results in delays and processing decisions being made based on possibly outdated information.

However, NIR spectroscopy, exemplified by the 2060 The NIR Analyzer from Metrohm Process Analytics, allows real-time manufacturing process monitoring, delivering rapid and accurate results.

Employing NIR spectroscopy enables manufacturers to make informed decisions, avoid cross-contamination, and maintain product integrity to meet consumer demands for safe and authentic food products.

References and Further Reading

- Rohman, A.; Che Man, Y. B. The Use of Fourier Transform Mid Infrared (FT-MIR) Spectroscopy for Detection and Quantification of Adulteration in Virgin Coconut Oil. Food Chem. 2011, 129 (2), 583–588. https://doi.org/10.1016/j.foodchem.2011.04.070.

- Shahbandeh, M. Wheat - statistics & facts. Statista. https://www.statista.com/topics/1668/wheat / (accessed 2023-07-12).

- Tao, C.; Wang, K.; Liu, X.; et al. Effects of Potato Starch on the Properties of Wheat Dough and the Quality of Fresh Noodles. CyTA - J. Food 2020, 18 (1), 427–434. https://doi.org/10.1080/19476337.2020.1768152.

- Yánez, E.; Ballester, D.; Wuth, H.; et al. Potato Flour as Partial Replacement of Wheat Flour in Bread: Baking Studies and Nutritional Value of Bread Containing Graded Levels of Potato Flour. Int. J. Food Sci. Technol. 1981, 16 (3), 291–298. https://doi.org/10.1111/j.1365-2621.1981.tb01017.x.

- Rady, A. M.; Guyer, D. E. Rapid and/or Nondestructive Quality Evaluation Methods for Potatoes: A Review. Comput. Electron. Agric. 2015, 117, 31–48. https://doi.org/10.1016/j.compag.2015.07.002.

This information has been sourced, reviewed and adapted from materials provided by Metrohm USA Inc.

For more information on this source, please visit Metrohm USA Inc.