Through a tailored approach to selecting and processing the right Graphene and nanomaterials for specific applications, Haydale has developed a ‘range’ of additives to increase the mechanical strength and enhance the electrical and thermal conductivity of products.

Haydale has developed an exciting portfolio of functionalised nano-enhanced additives for thermoset and thermoplastic composites, elastomers, inks, and coatings.

Image Credit: Haydale Limited

Functionalised Graphene

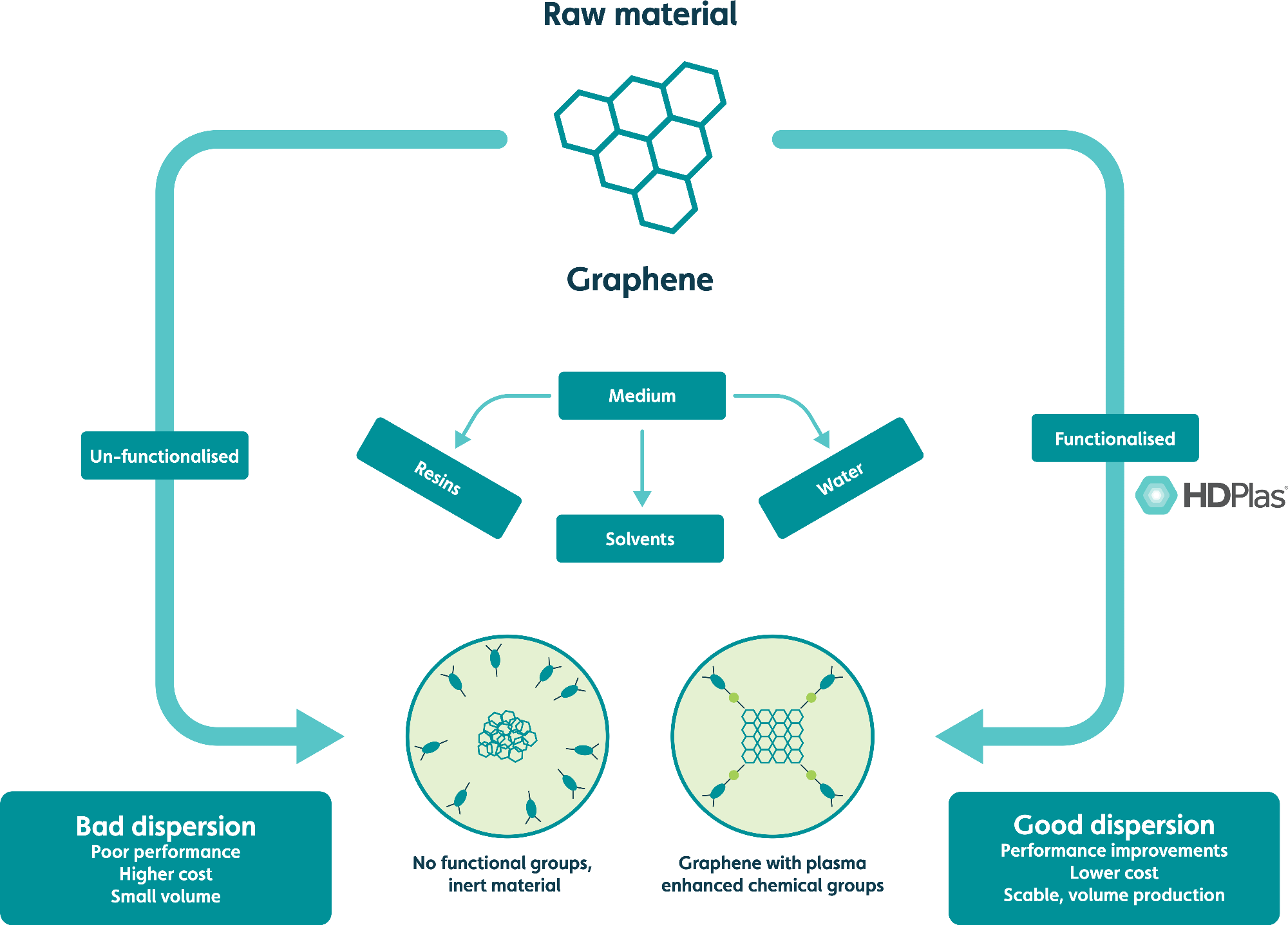

Graphene has qualities that should make it the ideal material for an extensive range of applications. However, its use has been limited due to it being inert and hard to mix. This limitation makes it challenging to produce on a large scale with low costs.

Many types of Graphene are manufactured primarily using chemical vapor deposition (CVD) and exfoliation from graphite for commercial applications. Haydale does not make Graphene, but the company has access to more than 250 grades that have been analyzed for matching to an application.

After the right materials are chosen for the application, the next step is to discuss how to use Graphene in a product.

The Graphene Challenge

The ‘Graphene Challenge’ is often used in reference to the fact that Graphene needs to be functionalized to remain stable within the matrix before it is used as an additive.

Graphene and other nanomaterials are inert in their raw form. To be able to use them in an application can involve chemical processes or methods that require lengthy production times through high-shear mixing.

Haydale has developed a powder-to-powder process that overcomes this problem called ‘plasma functionalisation.’

Plasma Functionalisation

Graphene and many other nanomaterials come in the form of a powder. They are inert and do not like to mix. A surface treatment is thus required to make them effective when used in an application.

People have been working on trying to solve this challenge using surfactants, mixing, or wet chemistry, but these methods fall short when it comes to stability and scalability. These methods can also be rather time-consuming, produce high volumes of effluent, and result in products that underperform.

Haydale’s HDPlas© method, on the other hand, is a dry, clean, and environmentally friendly process that is able to unlock the properties of Graphene, giving products an improvement in mechanical strength and increases in electrical and thermal conductivity.

Process Control

The process supports a fine control of the chemical structure of Graphene, allowing it to quickly disperse into a variety of media, including water, inks, and elastomers.

The patented ‘powder in, powder out’ process unlocks the potential of functionalised Graphene in a wide range of applications. This includes biomedical and security devices, heating products, tires, shoes, paints, and coatings.

Graphene is available in a range of powdered, aqueous, and solvent-based pastes or as a customized masterbatch. The Haydale functionalized Graphene product portfolio is easily incorporated into existing production processes.

This information has been sourced, reviewed and adapted from materials provided by Haydale Limited.

For more information on this source, please visit Haydale Limited.