Optimizing method development is vital for obtaining dependable particle-sizing results with laser diffraction. Yet, how confident can we be in flawlessly executing every standard operating procedure (SOP)? SOP Architect on the Mastersizer 3000+ is designed to walk you through each facet of method development, mitigating the chance of inadvertent deviations from optimal practices. The outcome is more robust, standardized methods that are error-free and efficiently crafted with minimum supervision.

Eliminating Errors in Method Development

Those who have experienced method development for laser diffraction understand the scenario well: you are dealing with a new type of sample, uncertain about handling a particular detail, and the one colleague who could offer guidance is unavailable.

Despite the feeling that pertinent documentation may exist somewhere, time restraints loom large, and an answer is imperative. Can you be sure that your ‘best guess’ is the best answer?

This precise predicament is exactly what SOP Architect on the Mastersizer 3000+ is designed to address. By actively guiding you through the most effective workflow for method development and providing prompts and expert advice at each stage, it facilitates the creation of SOPs that adhere to best practices, regardless of whether you are a novice or a seasoned user.

About the Mastersizer 3000+

Since its launch in 2012, the Mastersizer 3000 laser diffraction system has garnered a well-deserved reputation as a compact, versatile and high-performing tool for acquiring particle size distributions.

Its applications span various domains, including the assessment of powder flowability and packing, comprehension of drug dissolution rates, monitoring stability in food emulsions, and ensuring the optical performance of paints. As a result, the Mastersizer 3000 has become an indispensable asset across research and development and manufacturing sectors.

This success owes much to both its hardware and software components. Over the years, alongside numerous features and accessories, Malvern Panalytical has released two software modules benefiting all Malvern instruments: Smart Manager for optimizing uptime and usage and OmniTrust for ensuring regulatory compliance and data integrity.

The recently launched Mastersizer 3000+, in March 2024, continues this legacy, incorporating three additional software features to augment particle-sizing capabilities and facilitate informed decision-making:

- SOP Architect for standardized, streamlined method development

- Size Sure for improved confidence in routine measurements and method development

- Data Quality Guidance for assisting in making independent decisions on real-world samples

Coupled with its inherent flexibility and ease of use, the Mastersizer 3000+ is the premier choice for particle sizing.

SOP Architect on the Mastersizer 3000+

Using on-screen prompts and external guidance links, SOP Architect solves common pitfalls encountered during method development, such as modifying previous methods or excessive reliance on internal documentation. This makes it an ideal tool for individuals lacking confidence in the method development process or decision-making while also serving as a useful reminder for seasoned practitioners.

SOP Architect enhances clarity throughout every process phase by leading users through five stages of the method development workflow.

Stage 1: Sample and Material Details

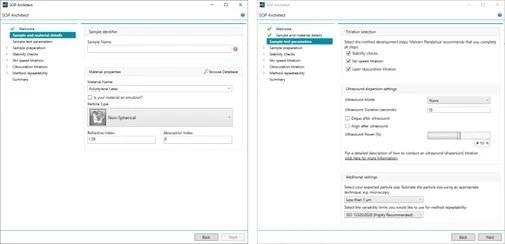

The SOP Architect process starts by prompting users to input several basic details, including sample name, material identity, particle type, refractive index, and absorption index (Figure 1).

Figure 1. An example of input screens for sample and material details on SOP Architect. Image Credit: Malvern Panalytical Ltd

The option to choose the tests is included. Beginners may prefer all options to be selected, while experienced users might opt to customize the stages. Additionally, The software guides users through selecting the dispersant via a beaker test, offering instructional videos and step-by-step procedures, which is particularly beneficial for those new to laser diffraction.

Stage 2: Stability Checks

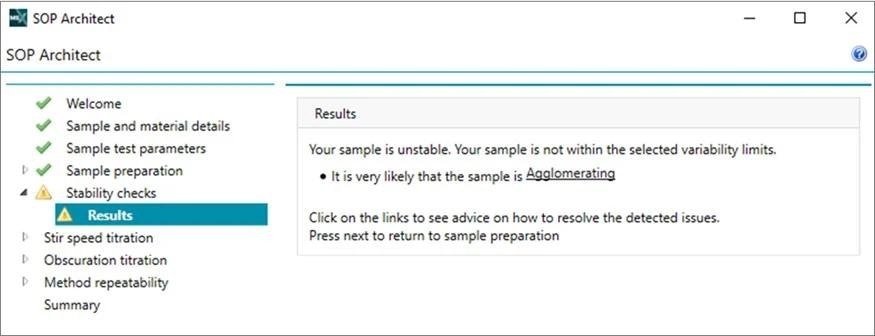

During this method development phase, SOP Architect ensures sample stability over time, utilizing default conditions suitable for most sample types.

First, the system runs a set of six measurements on a single aliquot. The software then looks for trends in the obscuration, cumulative volume distributions (Dv10/50/90), and total scattering data that would signify major sample changes, such as agglomeration, dispersion, or dissolution. It then reports back with an evaluation of the likelihood of the issue and directs users to pertinent advice on the optimal course of action (Figure 2).

Figure 2. An example of a stability check report generated using SOP Architect, showing a sample that may be agglomerating. Image Credit: Malvern Panalytical Ltd

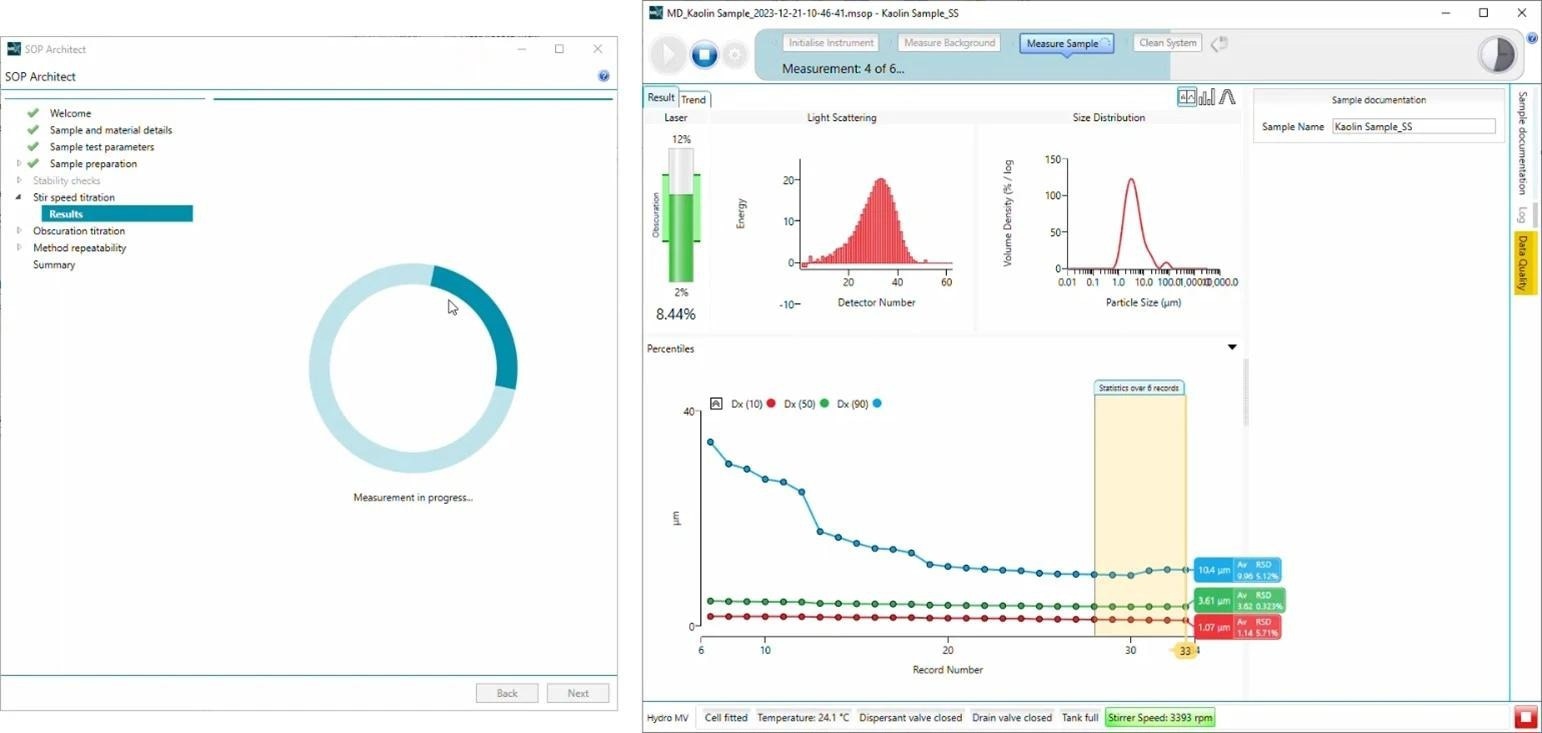

Stage 3: Stir Speed Titration

Optimizing the stirrer speed is crucial to obtain accurate results that faithfully represent the characteristics of the particles under examination, and this stage focuses precisely on this aspect. For instance, dense or large particles may settle too quickly at lower speeds, while emulsions could experience particle shearing at higher speeds.

Within SOP Architect, the system automatically runs six measurements at each of the following speeds:

- Standard: 1500, 2000, 2500, 3000 and 3400 rpm

- Emulsion: 1200, 1300, 1400, 1500, 1600 and 1700 rpm

The recommended obscuration for the sample at this stage is determined based on whether the expected particle size exceeds or falls below 1 µm (if the expected particle size is unknown, a default value is used). Using the collected data, the algorithm assesses particle size in relation to stirrer speed and identifies the region that has the most stable values. Within this range, the stir speed with the lowest standard deviation is suggested (Figure 3).

Figure 3. An example of a stir speed titration performed using SOP Architect. Image Credit: Malvern Panalytical Ltd

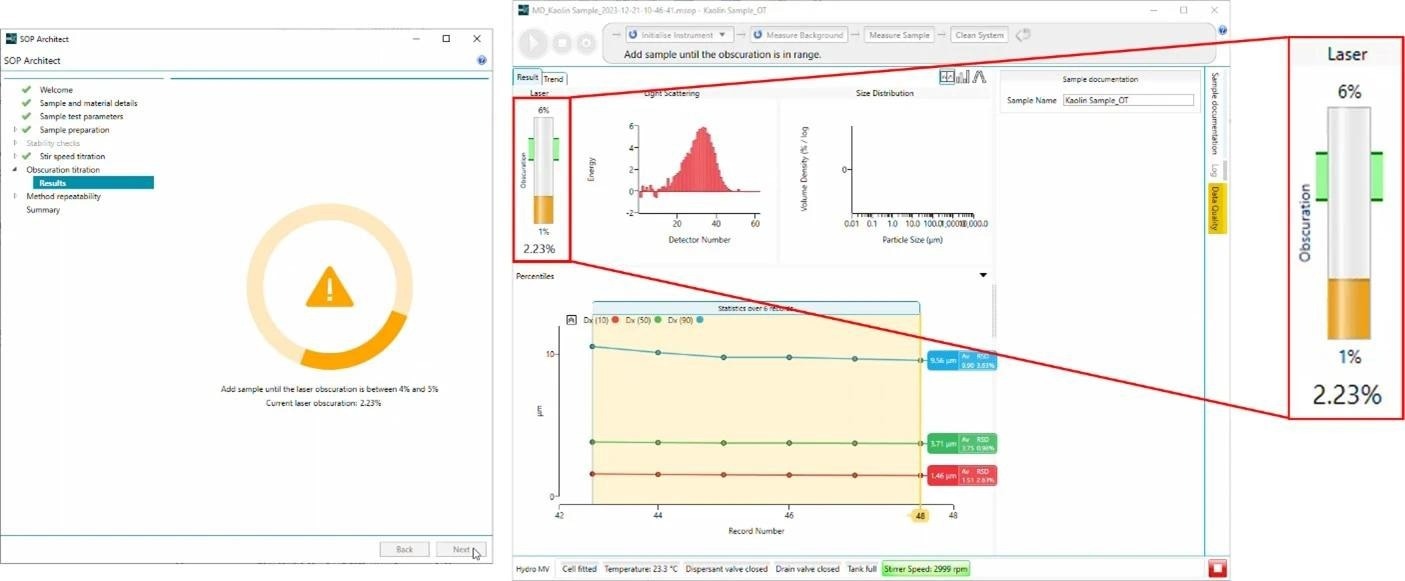

Stage 4: Obscuration Titration

Maintaining precise control over the concentration of the particles being tested is essential in wet measurements. A reliable indicator for this is the extent to which suspended particles obscure the laser beam, which is the subject of the second titration. This is a relatively ‘manual’ process in conventional method development, but with SOP Architect users benefit from prompts and guidance throughout.

Typically, five measurements are taken for each of six escalating concentrations, carefully chosen to align with six obscuration ranges: 2–3, 4–5, 7–9, 10–12, 15–17, and 19–21%. Another advantage of SOP Architect is its ability to streamline the assessment of obscuration ranges in instances of multiple scattering detection, thereby saving time, sample, and money.

A common challenge for beginners is attaining the desired concentration for each aliquot. Yet, with SOP Architect, the software displays the current obscuration level and indicates the target value, facilitating accurate adjustments from the outset (Figure 4).

Figure 4. An example of an obscuration titration using SOP Architect, showing the current and desired obscuration values. A similar interface is used for the stir speed titration. Image Credit: Malvern Panalytical Ltd

Stage 5: Method Repeatability

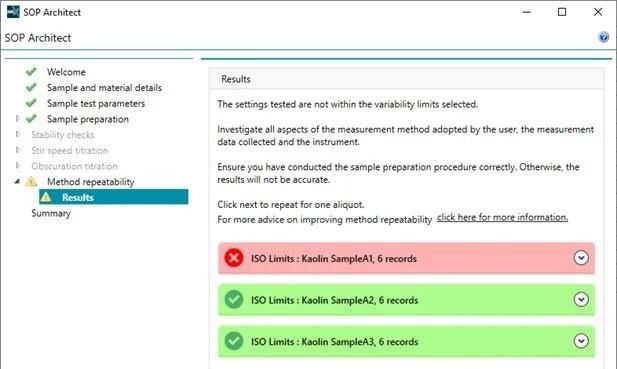

The final step in method development using SOP Architect is to assess the method's repeatability, which is a good indicator of overall data quality.

The software prompts users to run three sets of six measurements using a fresh aliquot. Each data set is passed through the algorithms for assessing RSD variability defined within the Data Quality Guidance module on Mastersizer 3000+ and assessed against the criteria for ISO 13320:2020 and USP variability (Figure 5).

Upon receiving an unexpected result, such as an aliquot failing, the software then guides users on what to do next, helping to improve the method development procedure.

Figure 5. An example of a method repeatability report was generated using SOP Architect, showing the red headers that appear when an aliquot fails a check and the green headers that appear when it passes. Expanding each header shows further information, including the Dv10, Dv50 and Dv90 values, and the RSD. Image Credit: Malvern Panalytical Ltd

Conclusion

With its structured processes and helpful guidance, SOP Architect offers particular advantages for those new to the laser diffraction technique. Even for users experienced in laser diffraction, having best practices embedded in the software, instead of having to remember it each time, reduces the likelihood of errors slipping through unnoticed and subsequent problems for data quality later on.

SOP Architect also fits neatly within the ‘ecosystem’ of SOP software on Mastersizer 3000+, which is particularly useful when users are required to run exactly the same method repeatedly, such as in regulated environments. Methods generated using SOP Architect use Malvern Panalytical’s ‘.sop’ file type, meaning they run on SOP Player and can be edited using SOP Editor.

In summary, using SOP Architect with Mastersizer 3000+ will help users to:

- Standardize or simplify method development

- Embed best practices in method development and achieve consistently high standards

- Reduce reliance on person-to-person knowledge transfer

- Incorporate Malvern Panalytical’s experience in their workflow

- Boost team independence with decision-making

- Move toward automation of their laser diffraction measurements with SOP Player

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical Ltd.

For more information on this source, please visit Malvern Panalytical Ltd.