The Dynamic Mechanical Analysis (DMA) method improves the sensitivity of measuring material stiffness, glass transition, and the effect of frequency on mechanical properties. It measures a material’s viscoelastic characteristics.

DMA analyzers provide accurate measurements of mechanical properties for both basic and complicated materials, making them dependable for product engineers working in applied research and materials development.

With the help of its cutting-edge Real View® camera system, which provides real-time observation during measurements, the DMA can better analyze unforeseen behaviors such as color shifts and sample damage. Even after the measurement procedure is finished, it guarantees the validation of data point dependability.

The DMA's extraordinarily broad measurement range and quick electronic response make it the ideal instrument for evaluating both soft and stiff samples and recording quick modulus changes.

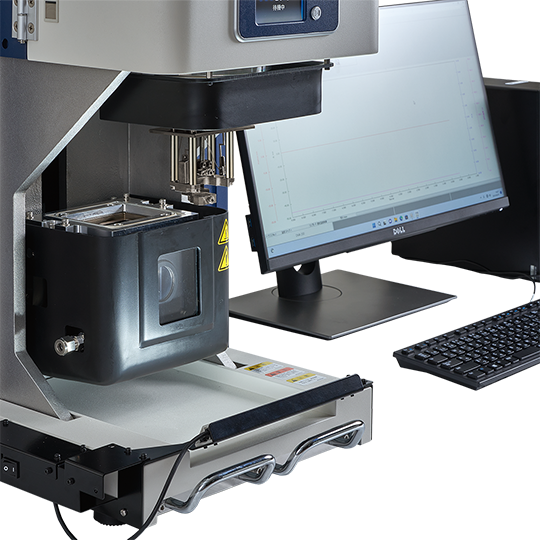

Image Credit: Hitachi High-Tech Analytical Science

Product Highlights

Comprehensive Material Characterization Made Easy

Video Credit: Hitachi High-Tech Analytical Science

- For the analysis of stiff materials, such as carbon fiber composites and other high-performance materials, use the 20 N force range

- The ability to access a wide applied force range with low output signal noise and 5E–6N resolution enables the resolution and identification of even the smallest transitions

- Select between air, liquid nitrogen (LN2), or electrical gas cooling. The LN2 cooling platform uses up to 30 % less energy than electrical gas cooling, which depends on power, removing external resources

- Ensure confidence in the results by validating them during or after analysis using the Lissajous monitor function

- The Real View system, numerous measuring modes, quick modulus change detection, and sophisticated analysis offer dynamic insights for research

- Maximize convenience with the user-friendly ‘Guidance Mode’ software, delivering step-by-step analysis and measurement help for non-experts. Advanced options for various applications are included as standard, including activation energy calculations and master curves (TTS)

- The DMA instrument adheres to ISO, ASTM, DIN, and JIS standards, with crucial specifications incorporated into the software, including ISO 6721-11, ASTM D7028-07, IPC 2.4.24.2, JIS K7095, and more

What Makes the DMA Instruments Unique?

Real View® Camera for Visibly Better Thermal Analysis

Combined, the DMA200 and the Real View camera system work flawlessly, enabling real-time observation of changes in the sample status during analysis. Changes in the sample’s size, shape, color, and other characteristics can be seen in high-resolution images. Images are captured and automatically timestamp-linked to the thermal analysis results, simplifying image processing and facilitating easy sharing.

Optional Data Input and Output Software Package

Boost productivity and minimize human mistakes with the automatic measurement input. To make data management simpler and more dependable, use a barcode reader to enter crucial information such as name, method file, and lot number.

Product Specifications

Source: Hitachi High-Tech Analytical Science

| . |

. |

| Deformation Mode Options |

Tension, single/dual cantilever, 3-point bending, shear, film-shear, compression |

| Maximum Force |

20 N |

| Modulus Range |

103 to 1013.5 Pa |

| Frequency |

Sinusoidal wave oscillation: 0.01 to 200 Hz, max 20 frequencies

Synthesis wave oscillation mode: 5 frequencies |

| Measurement Range |

105 to 1012 Pa(Tension),

105 to 1012 Pa(Dual-Cantilever Bending),

103 to 109 Pa(Shear),

104 to 1010 Pa(Film Shear),

105 to 109 Pa(Compression),

106.5 to 1013.5 Pa(3-Point Bending) |

| Temperature Range |

Liquid nitrogen cooling

-150 to 600 °C

Electrical gas cooling

-100 to 600 °C

Air cooling

RT to 600 °C |

| Sample Observation |

Real View® ready |

| Driving shaft |

Spring mounted (no compressed air required) |

| Sensor |

LVDT |

| Dimensions |

420(W), x 630 (D) x 725(H) mm |

*Deformation modes "Bending", "Shear", "Film Shear", "Compression" and "3-Point Bending" are optional.