Video Credit: Thermo Fisher Scientific – Materials & Structural Analysis

The Energy 11 Twin-Screw Extruder can be configured for various applications experienced in current battery research and development. The horizontally split, completely ported barrel enables flexible feeding of solid and liquid ingredients. Interchangeable die designs accommodate various materials, including dry granules, polymeric solid-state electrolytes, electrode films, and wet slurries. Eight accurately temperature-controlled zones along the barrel provide processing flexibility.

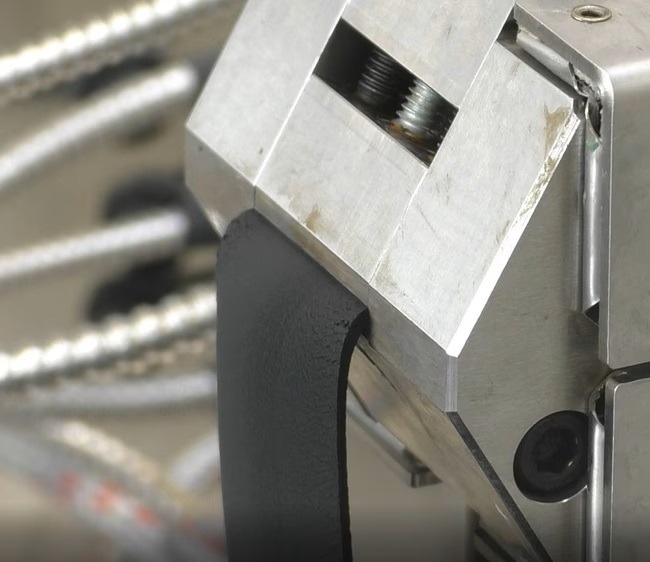

Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

Product Overview

The Energy 11 Twin-Screw Extruder assists in overcoming challenges in battery processing by enabling continuous and thorough mixing. The horizontally split barrel with fully ported ports allows for flexible feeding of solid and liquid ingredients.

The final product throughput ranges from 50 g/h to 5 kg/h. The extruder can be operated inside a fume hood or glovebox using the detachable control panel when necessary. All product contact parts are made of CPM® steel, specifically for the requirements in battery applications, minimizing the risk of metal abrasion in the final product.

With just one tri-clamp connection, the entire assembly of feedport, barrel, screw, and die can be detached. This ensures quick cleaning and prevents cross-contamination.

The Energy 11 Twin-Screw Extruder can significantly decrease solvent during mixing—from typically 60% down to 15%—due to its high shear force capability. Scaling to a manufacturing process reduces costs for solvents and offers the possibility of significant energy savings during the subsequent drying process.

Video Credit: Thermo Fisher Scientific – Materials & Structural Analysis

Specifications

Source: Thermo Fisher Scientific – Materials & Structural Analysis

| . |

. |

| Amperage |

16 A |

| Speed Range |

11 mm |

| Voltage |

230 V |

| Screw Diameter (Metric) |

11 mm |

| Heating Zones |

8 |

| Dimensions (L x W x H) |

890 x 490 x 425 mm |

| Barrel Length L/D |

40 L/D |

| Max. Temperature |

280 °C |

| Description |

Energy 11 Parallel Twin-Screw Extruder |

| Unit Size |

Each |