The exceptional mobility and tough industrial radiography conditions were taken into consideration when designing this incredibly durable and waterproof digital detector array (DDA).

- High Resolution

- Compact design

- The 10×24 cm active area is ideal for inspecting welds.

- Lightweight and ruggedized

- 2.2 kg/1 m drop test pass.

Important Features

Image Credit: DÜRR NDT GmbH & Co. KG

- Ideal for X-Ray and gamma sources.

- Electronics shielded for usage up to 350 kV.

- Highly robust design with a carry handle that can detach.

- High resolution 76 μm pixel pitch (6.5 lp/mm).

- Wireless access point integrated into the design.

- Connector for Gigabit Ethernet and power.

- Passes drop test (1 meter).

- Dust-tight and waterproof (IP67)

- For stationary and mobile applications

Technical Data

Source: DÜRR NDT GmbH & Co. KG

| |

DRC 1024 NDT |

| Active area |

97 mm x 233 mm (3.82" x 9.2") |

Dimensions

(H x W x D) |

132 mm x 335 mm x 30 mm (without handle) |

| Weight |

2.2 kg (4.9 lbs) |

| Number of pixels |

1280 x 3072 |

| Exposure time |

0.5 s to 180 s |

Image transfer time

(wired/wireless) |

1.9 s / 2.6 s |

| Max. energy |

350 kV (for long life in typical applications), Isotopes (higher energies possible) |

| Pixel pitch |

76 μm |

| Scintillator |

GOS |

| ADC |

16-bit |

| Interface |

Gigabit Ethernet, WLAN: 2.4 GHz (802.11abgn) / 5 GHz (802.11ac) |

| Battery |

Lithium-ion (11.25 V, 33.2 Wh) |

| Operating conditions |

0 to 45 °C (32 to 113 °F), 30 to 85 % humidity |

| Protection level |

IP67 (dust-tight and waterproof) |

| Housing |

Aluminum frame, carbon-fiber entrance window |

| Software |

DÜRR NDT D-Tect X |

| Scope of supply |

Detector, 2 batteries, battery charger, Ethernet and power adapter cable |

Sample Images

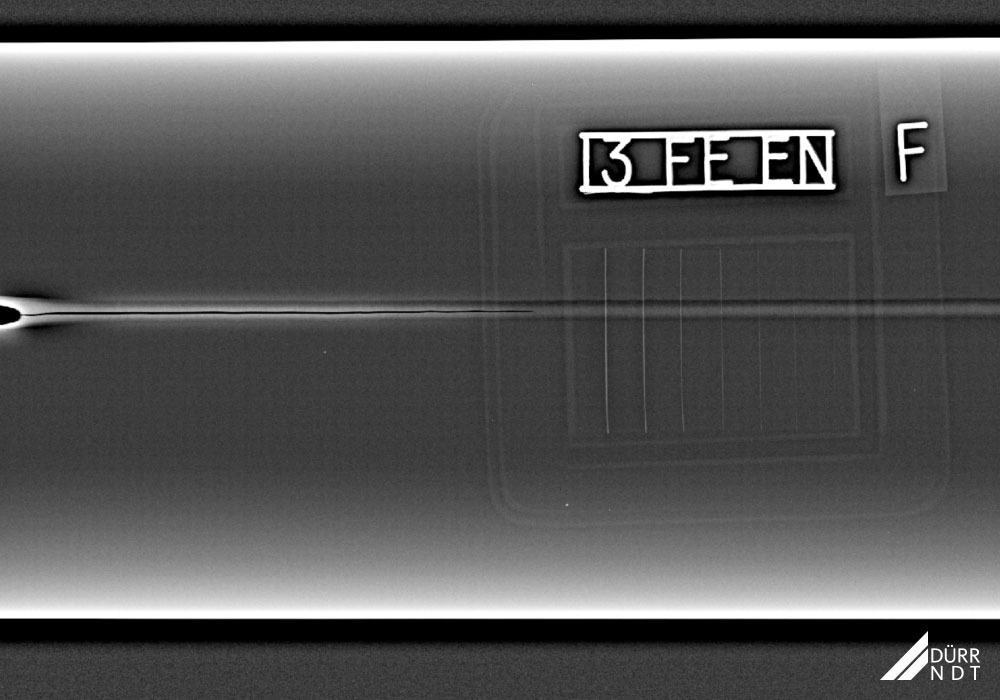

Thin-walled stainless-steel cylinder with longitudinal weld seam. Image Credit: DÜRR NDT GmbH & Co. KG

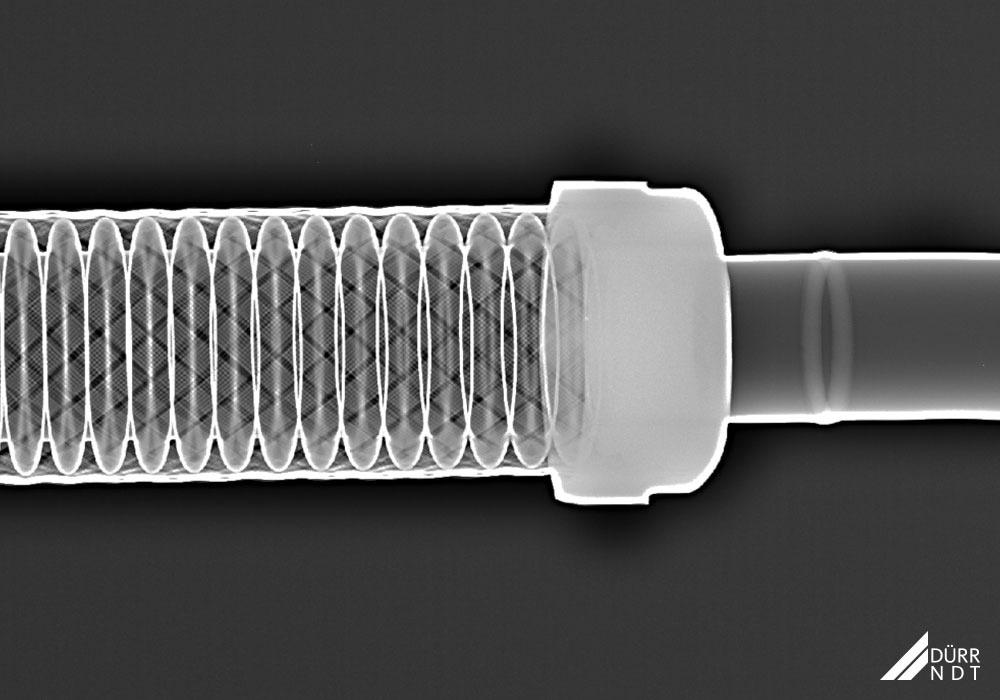

Flexible engine hose line with circumferential weld seam. Image Credit: DÜRR NDT GmbH & Co. KG