CompEAct offers quick and affordable sulfur and nitrogen assessment of liquids, gases, and LPG samples for refineries, quality control, and contract laboratories in an era of constrained lab resources and growing sample numbers.

Benefits

- Accurate assessment of sulfur and nitrogen content

- Optimized sample throughput for increased efficiency

- Minimum maintenance requirements, maximum safety

- Space-saving design with a compact footprint

- Efficient, time-saving attributes: Pre-calibrated, factory-tuned, swift measurement processes, and continuous 24/7 operation

Simplify Quality Control with compEAct

Reduce expenses and increase efficiency with compEAct's analysis times ranging from 2 to 5 minutes and a high capacity for sample processing.

This system provides field-tested, ready-to-implement standard methods that adhere to the relevant regulations, removing the need for time-intensive method development and optimization.

Designed for continuous, unattended operation 24/7, these analyzers also support remote access.

Features

- Intuitive touchscreen interface providing complete access to a comprehensive method repository

- Broad linear measurement range featuring minimal detection thresholds (N: 15 ppb, S: 5 ppb)

- Automatic supervision and fine-tuning of all process parameters

- The most compact design available, consolidating all essential system components within a single unit (occupying less than 0.3 m2)

Image Credit: Analytik Jena US

Image Credit: Analytik Jena US

Image Credit: Analytik Jena US

Image Credit: Analytik Jena US

The Analyzer That Thinks

The compEAct, despite its compact size, delivers remarkable performance. It excels in high sample throughput, swift analysis times, and user-friendly software, resulting in cost reduction and heightened productivity.

Image Credit: Analytik Jena US

With compEAct, users can bid farewell to laborious maintenance routines and manual system inspections. Its low detection limits ensure compliance with industry standards such as ASTM, ISO, UOP, or IP.

CompEAct helps users with every facet of their lab work. Unplanned downtime for maintenance and system inspections is not a concern because of the analyzer’s self-monitoring system.

The EAsy Protect system continuously oversees and optimizes critical process parameters. The maintenance assistant keeps you informed about impending maintenance needs, reducing both cycles and costs.

The EAsy Protect system actively oversees and fine-tunes all crucial process parameters in real time. The maintenance assistant informs users of upcoming maintenance requirements and minimizes maintenance cycles and costs.

Additionally, the built-in Auto-Protection System ensures dependable operation and extends the lifespan of vital system components. Its compact design incorporates a high-contrast touchscreen, which is user-friendly even when wearing gloves. The nano-coated surface is also resistant to chemical and mechanical wear.

The degree of automation for compEAct is adaptable to each user's requirements – from manual handling of just a few samples a week up to fully automated, unattended operation around-the-clock in high-throughput laboratories.

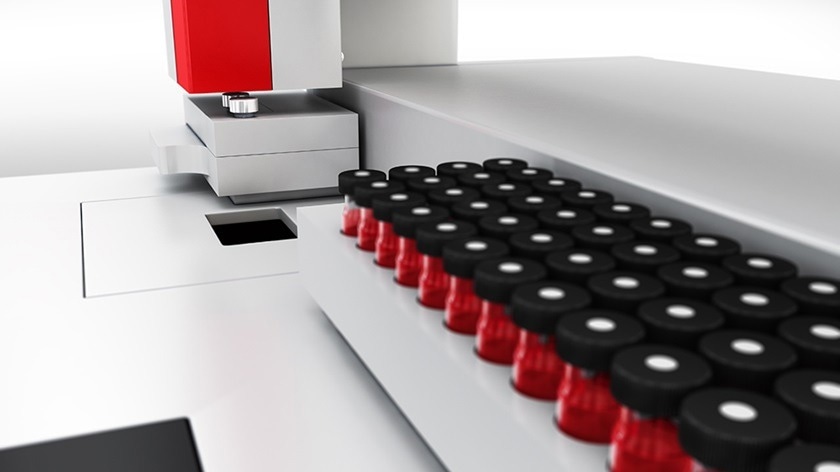

The range of accessories includes autosamplers from 18 to 120 positions with flexible sample volumes and dosing speed, as well as an autoinjector for automated injection without using an autosampler. Additionally, users can add one of the matrix-optimized gas sampling modules for simplified and safe LPG and gas analysis.

In the context of the oil and gas industry, compEAct offers valuable time-saving and workflow simplification benefits, which are particularly crucial given the industry's challenges, including increasingly stringent regulations and a shortage of skilled personnel.

The accurate determination of sulfur and nitrogen impurities plays a pivotal role in ensuring product quality and optimizing processes. This is of paramount importance for control laboratories in both refineries and alternative fuel production facilities.

The compEAct detector spans an extensive concentration range, accommodating everything from high levels in process streams to ultra-trace amounts in the final, pure products, all without the need for dilution or enrichment steps. Suitable applications also include quality control for organic chemicals, solvents, and bio-chemicals.

Depending on user requirements, users can select from two application-optimized versions of the compEAct elemental analyzer: compEAct N for total nitrogen content analysis and compEAct S for total sulfur content analysis.

Furthermore, compEAct S MPO is the recommended choice for interference-free sulfur (TS) determination in fuel analysis and other refinery applications.

compEAct — Choose the EAsy Way

Video Credit: Analytik Jena US

Products

compEAct N

Elemental analyzer for total nitrogen (TN) determination.

Image Credit: Analytik Jena US

compEAct S

Elemental analyzer for total sulfur (TS) determination.

Image Credit: Analytik Jena US

compEAct S MPO

Elemental analyzer for interference-free sulfur (TS) determination in fuels and other refinery products.

Image Credit: Analytik Jena US

Applications

Oil and Gas

- Measuring sulfur content in automotive fuels using ultraviolet fluorescence in accordance with EN ISO 20846

- Determining trace nitrogen levels as per DIN 51444

- Total sulfur determination in aromatic hydrocarbons and allied chemicals according to ASTM D7184

- Total sulfur analysis in aromatic hydrocarbons and allied chemicals following ASTM D7183

- Total nitrogen analysis in bio-based fuels in compliance with ASTM D4629

- Swift and dependable total sulfur assessment in liquefied pressurized gases (LPG) as per ASTM D6667, ASTM D7551, and DIN EN 17178 (EN)

Technical Data

Source: Analytik Jena US

| |

Min. measurement time |

Sample Pressure |

Injection Volume |

Detector |

Sample Supply |

Digestion Mode |

compEAct N

450-300.003 |

3 min |

gas: up to 200 bar

LPG: up to 35 bar |

liquids: 0 - 100 µL

gases: 0 - 100 mL

LPG: 0 - 50 µL |

N: CLD |

vertical, semi- or fully automated (accessories required) |

High-temperature combustion, catalyst-free |

compEAct S

450-300.001 |

3 min |

gas: up to 200 bar

LPG: up to 35 bar |

liquids: 0 - 100 µL

gases: 0 - 100 mL

LPG: 0 - 50 µL |

S: UVFD |

vertical, semi- or fully automated (accessories required) |

High-temperature combustion, catalyst-free |

compEAct S MPO

450-300.002 |

3 min |

gas: up to 200 bar

LPG: up to 35 bar |

liquids: 0 - 100 µL

gases: 0 - 100 mL

LPG: 0 - 50 µL |

S: UVFD, equipped with MPO technology |

vertical, semi- or fully automated (accessories required) |

High-temperature combustion, catalyst-free |