For the first time 3D-Micromac AG has presented a laser drilling technology for upcoming generations of inkjet nozzles.

3D-Micromac AG, the industry leader in laser micromachining, has introduced a novel laser drilling technology at Laser 2015. The sophisticated machining strategy is perfectly suited for machining of new generation inkjet nozzles.

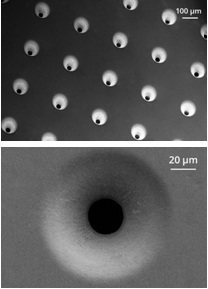

Laser machined inkjet nozzles in stainless steel

Laser machined inkjet nozzles in stainless steel

The growing demand for high throughput inkjet printing systems and resistance to acidic inks or abrasive materials like nanoparticles requires highly resistant nozzle materials in combination with special nozzle layouts. While established fabrication technologies like electro forming, etching, and laser processing with long pulse durations increasingly face their limits, 3D-Micromac AG has developed a sophisticated laser process using ultrashort pulse lasers. Compared to traditional manufacturing processes, digital laser machining provides the highest degree of flexibility in the generation of freeform nozzle geometries, different nozzle shapes and various nozzle tapers. The use of ultrashort pulse lasers guarantees a perfect entrance and exit quality, and excellent surface roughness in highly resistant nozzle materials, such as titanium, glass, stainless steel, etc.

Since laser machining is contactless, there is no tool wear, and expensive or polluting consumables are not necessary. This results in the sustainable manufacturing solution microDRILL™, combining high throughput with extremely low manufacturing costs. The new system is based on existing production systems for dedicated inkjet nozzles that have successfully been used in industrial production over several years.

About 3D-Micromac AG

3D-Micromac AG is the industry leader in laser micromachining. We develop processes, machines and turnkey solutions at the highest technical and technological level. Our aim is to provide superb customer satisfaction even for the most complex projects.

3D-Micromac delivers powerful, user-friendly and leading edge processes with superior production efficiency. These proprietary technology innovations are now readily available on a worldwide scale.

For more information, visit the company’s website at http://www.3d-micromac.com