Jan 22 2016

Polyimides are considered to be a lot denser than metals and are capable of withstanding chemically aggressive solvents and heat. This is the main reason why polyimides remain popular in the industry especially in aerospace applications or as an insulation layer used on PCBs. Researchers at TU Wien have developed a synthesis procedure, providing new possibilities for polyimides. For the first time, it is now possible to develop angular polyimide particles.

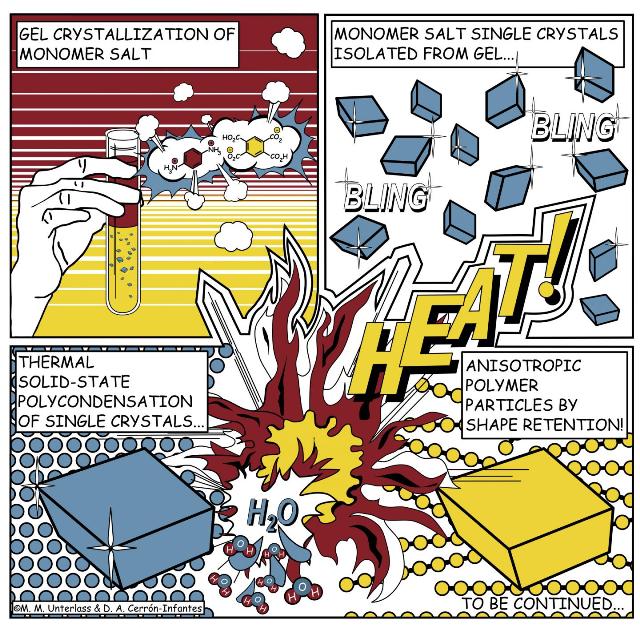

Gel crystallization produces salt, which is then turned into polyimide. (Credit: TU Wien)

Gel crystallization produces salt, which is then turned into polyimide. (Credit: TU Wien)

"Small plastic particles are usually obtained as spherical objects." says Miriam Unterlass from the Institute of Materials Chemistry at TU Wien. However, roundish particles are poorly suited for many applications."Particle-containing liquids are extensively used as paints and protective coatings. The geometric shape of the particles then determines how the particles are arranged and move within the liquid."

It is not possible to obtain uniform dryness for a number of dispersions, due to the production of an unfavorable current moving particles during the evaporation process.

Despite several attempts, little success has been made in providing an angular shape for polyimide particles and other similar materials. Miriam Unterlass' team have recently come up with a new approach, first using two different molecules to form an angular salt crystal. The two molecules are linked in a disorganized manner, and the salt crystal is developed from a gel reaction. This gel reduces the pace of the molecules and slows down the reaction to develop high-quality, well-ordered and visible crystals comprising a diameter of hundreds of micrometers.

The important step begins by heating the crystals to produce a chemical reaction. This is followed by the conversion of the salt crystal into a solid-state polyimide material, where the salt crystal does not melt or dissolve. Water is developed as a harmless byproduct and the original salt crystal’s angular shape is retained and an angular polyimide particle is produced without any curvature.

The material continues to remain stable up to a temperature of 700 degrees and resists any kind of solvent. This type of resistant particle can be used with other materials to develop special materials used for space traveling or protective coatings.

Gel crystallisation, high-performance materials, solid-state synthesis and crystallography are areas that are rarely combined. It was not easy to bring such different approaches together, but it was definitely worth it in the end.

Miriam Unterlass, Institiute of Materials Chemistry at TU Wien

The researchers are hoping that other types of high-performance materials can be synthesized using the same method of producing a salt in gel, which is converted into crystal shaped polymer particles when heated. The researches are currently performing other experiments.