Nov 1 2017

The steel used for constructing a building can be protected from being buckled and failing during a fire by adding additional coats of “paint.”

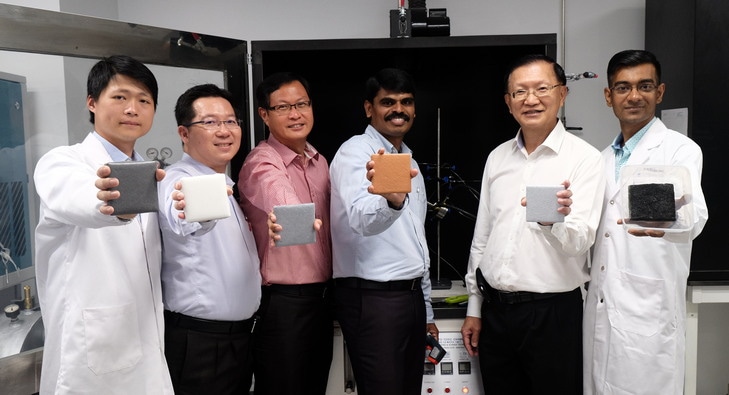

(From left) NTU PhD student Mr Ng Yan Hao; Principal Engineer at JTC’s Civil and Structural Department Mr Ng Kian Wee; NTU Professor Tan Kang Hai; NTU Assistant Professor Aravind Dasari; Director, Technical Services Division of JTC and Co-Director of the I3 Centre, Mr Koh Chwee; and NTU research fellow Dr Indraneel S Zope; holding steel plates coated with FiroShield of different colors. Credit: Nanyang Technological University, Singapore

(From left) NTU PhD student Mr Ng Yan Hao; Principal Engineer at JTC’s Civil and Structural Department Mr Ng Kian Wee; NTU Professor Tan Kang Hai; NTU Assistant Professor Aravind Dasari; Director, Technical Services Division of JTC and Co-Director of the I3 Centre, Mr Koh Chwee; and NTU research fellow Dr Indraneel S Zope; holding steel plates coated with FiroShield of different colors. Credit: Nanyang Technological University, Singapore

Researchers at Nanyang Technological University, Singapore (NTU Singapore) and national industrial developer JTC proposed this concept while looking for a commercially feasible solution to safeguard reinforced concrete from underground fires.

The interdisciplinary team spent 2 years on in-depth research and development, and they invented an economical 3-in-1 coating that provided improved fire and corrosion protection.

The new coating, which is known as FiroShield, is less laborious and less costly to apply, and can aesthetically function similar to normal paint.

Prevalent steel structures in buildings are normally coated with a fire-resisting layer to protect the bare metal from fire and to fulfill the fire protection standard of 2 hours, which is intended to provide occupants of the building adequate time to vacate the building. Prevalent traditional intumescent coatings are very thick, costly and strenuous to apply.

When compared to the prevalent coatings, the coating produced in Singapore can be coated on bare steel without sand blasting to prepare the surface, and it will safeguard the material from fire for 2 hours without being destroyed. Hence, the total time for coating can be decreased by half when compared to traditional coatings, thus reducing the man-hours needed. The investigation also tested FiroShield on other construction materials (e.g. laminated timber and reinforced concrete) which exhibited the same exceptional endurance.

In order to accomplish a 2-hour fire rating, FiroShield needs to be coated for only five layers, as against traditional coatings that have to be coated for nearly 15 layers. Thus, it can be applied two times faster and is less expensive by nearly 50% owing to its lower manpower and materials cost requirements.

As well as its easy application and fire-retardant characteristics, FiroShield can also prevent the corrosion of steel surfaces, which cannot be achieved by any other fire coatings found on the market at present.

It is anticipated that FiroShield will last longer upon being exposed to weathering elements like ultraviolet rays and moisture. On being subjected to laboratory weathering tests, performance of FiroShield was reduced only by 2%, as opposed to a reduction of nearly 75% in the case of traditional coatings. This minimizes the frequency of inspections and the maintenance expenses over the lifetime of a building.

Assistant Professor Aravind Dasari from the School of Materials Science and Engineering and Professor Tan Kang Hai from the School of Civil and Environmental Engineering led the research team.

The team also includes Dr Indraneel S Zope and Mr Ng Yan Hao from NTU, and also Ng Kian Wee, Principal Engineer at JTC’s Civil and Structural Department, who offered his experience from engineering projects. The interdisciplinary perspective connecting the materials with the structures was an important aspect of this study.

According to the researchers, the insights they have acquired from many years of research on the various features of polymers and combustion, together with civil and structural engineering experience, assisted in streamlining their strategy.

Their coating achieves its strength from a balanced combination of additives which together function optimally to enable simultaneous chemical reactions while being subjected to exceptionally higher temperatures. They were quite sure that they had zeroed in on the precise formula when they found that they could evenly coat FiroShield on steel samples by using a spray gun.

In a fire, our coating forms a compact charred layer that acts as a protective barrier against the heat, while typical fire coatings will also form a charred layer, those are thick and foam-like, which can fall off easily and leave the steel exposed to the fire. What we aimed at was an innovative coat that works differently from conventional intumescent coatings and can stick to the steel surface for as long as possible under high temperatures, and yet has durability and weather resistance under normal conditions without a need for a top coat of paint.

Assistant Professor Aravind Dasari, School of Materials Science and Engineering,(I3 Centre).

According to Mr Koh Chwee, Director, Technical Services Division of JTC and Co-Director of the I3 Centre, by partnering with academic institutions such as NTU, JTC hopes to create innovative and futuristic solutions to improve construction productivity and safety for its industrial infrastructure projects.

“The ease of application of this new fire and corrosion resistant coating on steel structures will help reduce labour-intensive work, thus improving productivity and enabling faster coating of prefabricated steel components. More importantly, the new coating’s ability to maintain superior adhesion under high temperatures leads to increased building safety for occupants. We are confident that the new coating will be able to reduce both paint material and labour costs, and become a new alternative to other fire protection products,” stated Mr Koh.

According to Professor Chu Jian, Interim Co-Director of the I3 Centre, the new coating is one of the successful instances of industry and academia research collaborations, as NTU has been successful in acquiring on relevant industry knowledge from JTC while offering technological know-how and research skills to create an innovative solution that will be advantageous to the building and construction industry.

Combination of materials used for coating

The innovative coating’s base material includes synthetic resins, which are polymers usually used to produce paints. In order to incorporate corrosion- and fire-retardant characteristics in the coating, Assistant Professor Dasari and his colleagues added a formulation of common chemicals, including an endothermic chemical, in order to absorb heat to initiate a chemical reaction that makes the coating firmly adhere to the steel.

The researchers also developed a coating that had assorted colors. They achieved this by adding pigments to the mixture, thereby accomplishing the aesthetics of normal paint.

Paint manufacturers aiming to add the advantages of FiroShield to their products will find that commercialization is very easy because the advancement is just dependent on adding key chemicals to their paint production procedure.

For the next stage of development, FiroShield is to be sent to the United Kingdom for an industry certification, incorporating a load-bearing fire test, which at present cannot be carried out by any of the facilities in Singapore.

The proprietary formulation of the FiroShield has been filed with the innovation and enterprise arm of the NTU, NTUitive, and on the completion of this certification, NTUitive will collaborate with JTC to investigate options for commercialization.

Once the certification is achieved—anticipated to be in April 2018—the innovative coating will be coated on steel structures in the upcoming JTC Logistics Hub. The joint study group will also partner with suitable agencies to expand this technology on a wider scale.

Using this technology, Assistant Professor Dasari will also collaborate with JTC at the I3 Centre to create a different kind of advanced coating for the construction and building industry that has more useful characteristics apart from corrosion and fire resistance.

Started in the year 2011, the goal of the NTU-JTC I3 Centre is to introduce avant-garde industrial infrastructure solutions to overcome challenges of Singapore and its companies in fields such as productivity, safety, and resource and manpower restrictions.