Writing in the journal Energies, a team of scientists from Canada and Mexico has investigated the production of biofuels from waste cheese whey.

Study: Cheese Whey as a Potential Feedstock for Producing Renewable Biofuels: A Review. Image Credit: New Africa/Shutterstock.com

Cheese Whey Waste: A Critical Environmental Issue

The food and agricultural industrial sectors are essential for meeting the nutritional requirements of the growing world population. Dairy products are one of the most widely consumed types of food globally, with foodstuffs such as milk, cheese, yogurt, and desserts being produced and sold in vast quantities annually.

As with every industry, however, the dairy industry produces significant amounts of waste during manufacture. Several agro-industrial residues are produced during dairy production, with cheese whey in particular gaining special research attention due to the vast quantities of this critical waste material produced. In excess of 160 million tons of cheese whey is generated annually across the world.

The disposal of this material is problematic, and due to the environmental harm it can cause, governments in multiple jurisdictions have introduced regulations to control the amount of untreated cheese whey waste which enters water bodies or soil.

The ecological damage caused by untreated cheese whey is well-recognized by researchers. This agro-industrial waste causes eutrophication in water bodies and affects the pH of soil, increasing its acidity, depending on the type of discarded whey. Cheese type, curding processes, and milk source all affect the acidity of contaminated soils.

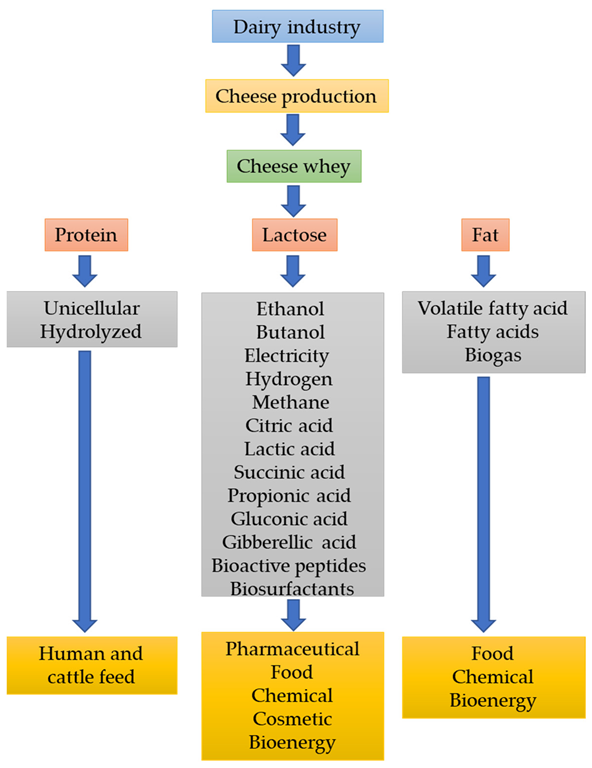

Biorefinery concept of cheese whey. Image Credit: Osorio-González, C.S et al., Energies

Producing Biofuels from Cheese Whey

Recognizing the scale of cheese production and environmental contamination caused by waste products such as cheese whey, research has turned in recent years to utilizing cheese waste products for value-added products in line with the concept of the circular economy.

Biofuels are a cleaner alternative to fossil fuels, and significant research has been conducted into producing them from agro-industrial waste streams. Some studies have explored the use of secondary whey products from cottage cheese production to produce these sustainable fuels. Limitations in the use of this substrate have been identified by researchers, such as low solid content, high biological demand, and increases in acidity.

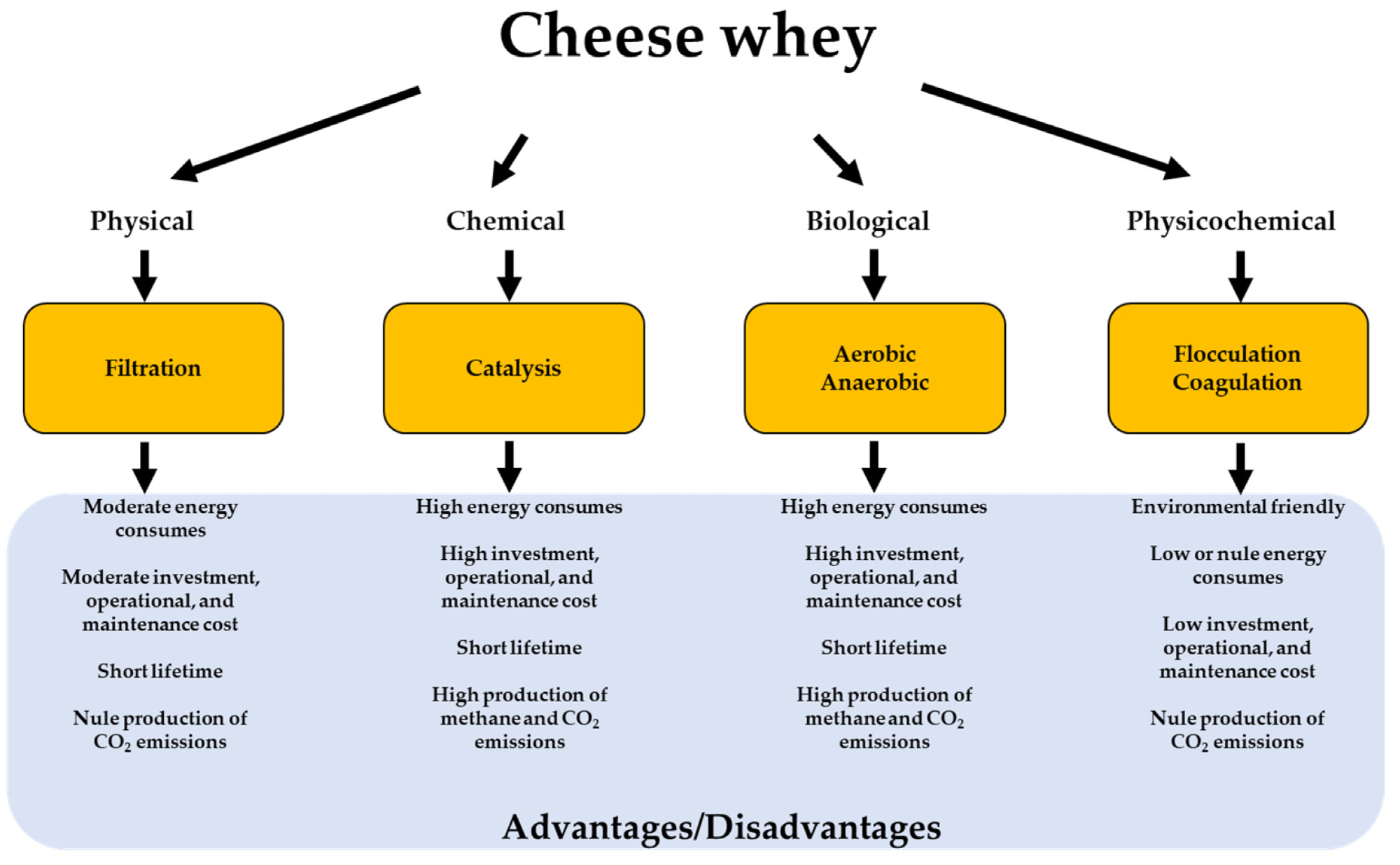

Several processes are utilized to treat cheese whey for the production of value-added products such as biofuels, each with its distinct advantages and disadvantages. Physical, chemical, biological, and physiochemical processes are all used for this purpose. Utilizing this key dairy industry waste stream can help meet the growing global demand for renewable and sustainable energy production.

Conventional process to treat cheese whey. Image Credit: Osorio-González, C.S et al., Energies

The Research

The paper in Energies has provided a timely review of the recent advances in the use of cheese whey waste for the value-added production of biofuels such as biodiesel, biomethane, biohydrogen, and bioethanol. The paper also provides an overview of technologies and microorganisms currently used for this purpose.

Production Status and Whey Properties

In 2020, 183 million tons of cheese whey were produced worldwide. Four types of milk are commonly used to produce cheese: cow, sheep, goat, and buffalo. Two types of whey are produced, acid and sweet, with acid whey the result of directly using organic acids and the production of lactic cultures, whereas sweet whey is produced by the coagulation of milk proteins with animal and microbial enzymes.

The physiochemical properties of the different types of whey are the direct result of the processes used during production. Chemical composition varies by milk source, such as moisture, total solids, lactose percentage, protein content, fat content, ash content, and pH values.

The technologies required for the value-added synthesis of products such as biofuels are expensive, which limits their use in small and medium-size cheese producers. Using this substrate as a carbon source for microorganisms produces several secondary metabolites such as organic acids, enzymes, and biofuel components. Producing biofuel from cheese whey substrates improves the income of producers as well as reduces environmental impacts.

Biofuel Production from Cheese Whey

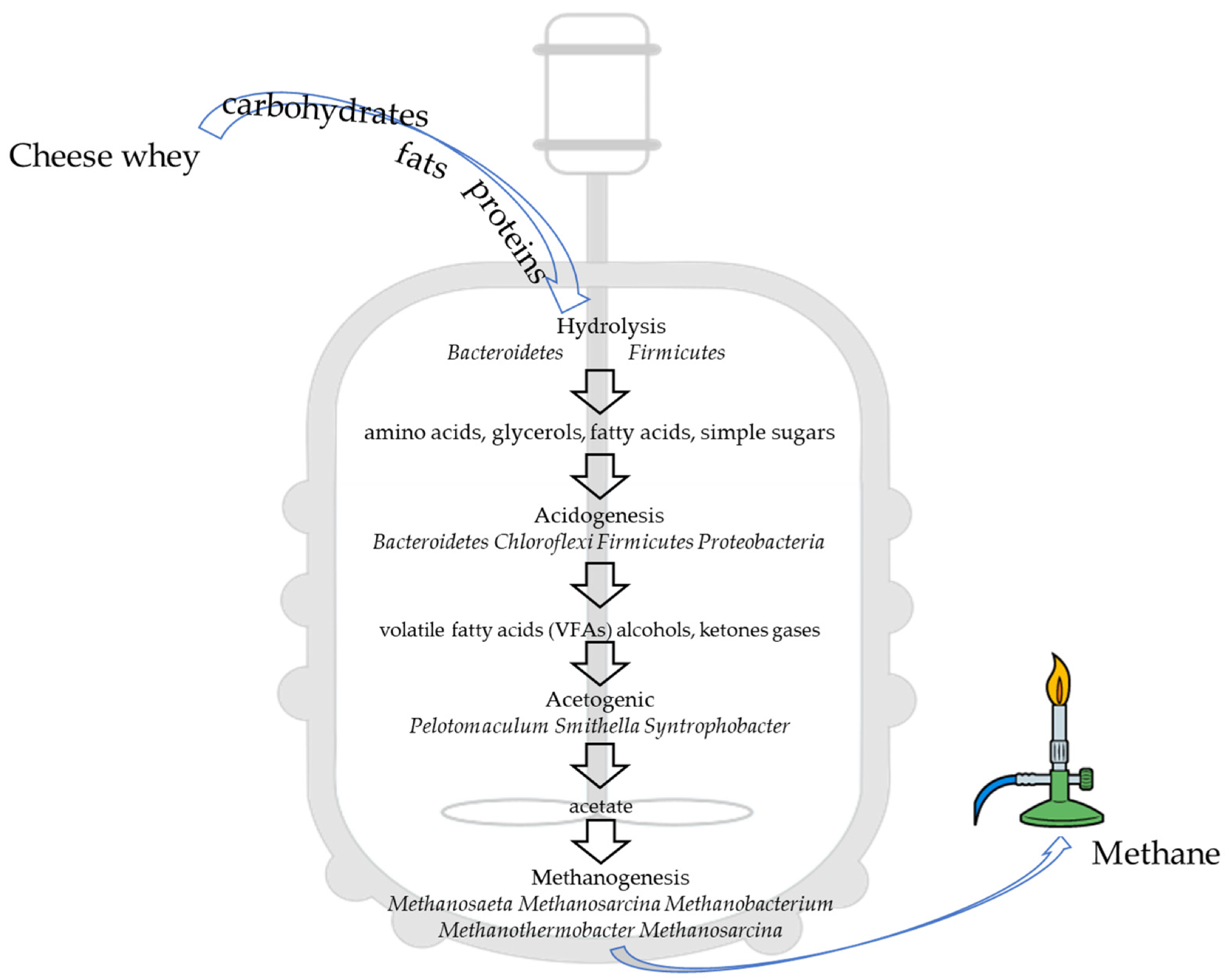

In order to produce value-added biofuel products, several important parameters and factors need to be considered by researchers. For biomethane and biogas production, cheese whey can be used in pure powdered form or in co-digestion modes in bioreactors, with waste products such as sugarcane vinasse, sugarcane stillage, and poultry slaughterhouse sludge explored over the past decade.

Cheese whey presents a sustainable alternative to fossil fuels for biohydrogen, with dark fermentation producing the highest yields. However, this process is challenging, and processes must be optimized to produce these high yields. Development of new microbial strains will aid the process. Bioethanol production can be enhanced through the use of wild ethanologenic microbial strains which can metabolize lactose.

Cheese whey is a low-cost, renewable, and abundant feedstock for the production of bacterial lipids which are essential for biodiesel synthesis. Substrates such as deproteinized cheese whey, ricotta cheese whey, whey permeates, and secondary cheese whey wastewater have been explored in recent research. These materials have been used as substrates for strains such as M. circinelloides and W. anomalus.

Main steps involved in anaerobic digestion processes. Image Credit: Osorio-González, C.S et al., Energies

In Conclusion

The paper has provided an in-depth review of current research perspectives on using cheese whey for the production of sustainable biofuels. A low-cost, abundant, and renewable material, valorizing this dairy industry product will help to reduce the environmental impact and waste production in the dairy industry and can play a key role in the green economy of the future.

Further Reading

Osorio-González, C.S et al. (2022) Cheese Whey as a Potential Feedstock for Producing Renewable Biofuels: A Review Energies 15(18) 6828 [online] mdpi.com. Available at: https://www.mdpi.com/1996-1073/15/18/6828.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.