Scientists from the National Research Center in Cairo, Egypt, have reported the development of a hydrophobic thin film coating for harvested fruit preservation. Their findings appear in the journal Scientific Reports.

Study: Synthesis of a new hydrophobic coating film from stearic acid of buffalo fat. Image Credit: designium/Shutterstock.com

Ensuring the Quality of Fresh Fruit and Vegetables

Fresh fruit and vegetables are an essential part of a healthy diet, possessing good nutritional benefits due to the presence of organic acids, vitamins, minerals, sugars, phenolic compounds, and carotenoids.

The valuable chemicals in fresh fruit and vegetables have many health benefits, such as antioxidant properties, anti-inflammatory properties, and anti-coagulant properties, and helping to prevent potentially fatal conditions like heart disease.

Ensuring the freshness and quality of fruit and vegetables is essential, and severe post-harvesting quality issues can occur due to mechanical damage, chemical action, and microbial activity. Environmental factors in the supply chain, from transportation to marketing processes, such as humidity, vibration, and shock, reduce the quality and shelf life of products.

Furthermore, these products have a limited shelf life, which limits long-distance transportation, and they are not available all year round. The various issues across the entire food supply chain lead to product waste and economic loss. To overcome these critical challenges, researchers have developed improved storage and preservation techniques over the years.

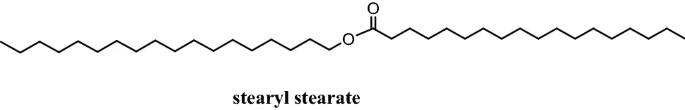

Chemical structure of stearyl stearate. Image Credit: Soliman, H.A & Zahran. H.A., Scientific Reports

Biodegradable Films

Packaging technology has evolved over the span of the past several decades, offering improved preservation of fruit and veg and, thus, extending their shelf lives and enhancing the quality, freshness, and nutritional content of products. Suitable packaging can prevent issues such as gas exchange, moisture, microbial growth, firmness loss, and various physiological disorders.

Thin film packaging technologies have been the subject of intense research in recent years, with various synthetic and organic-based polymers and materials explored by academics in the food production sector. Bio-derived materials have emerged as viable alternatives to synthetic polymers because of benefits such as biodegradability, biocompatibility, non-toxicity, and sustainability.

The use of biodegradable thin films overcomes several reported issues with synthetic packaging, such as waste, the use of non-renewable petrochemical-derived products, and carbon emissions produced during plastics manufacture.

Biodegradable films can be easily functionalized with useful properties such as antimicrobial behavior to create antimicrobial films and offer the additional benefit of being edible. Natural material sources such as cellulose, starch, gelatin, and milk proteins can be used to manufacture organic thin film coatings for fresh vegetable and fruit products.

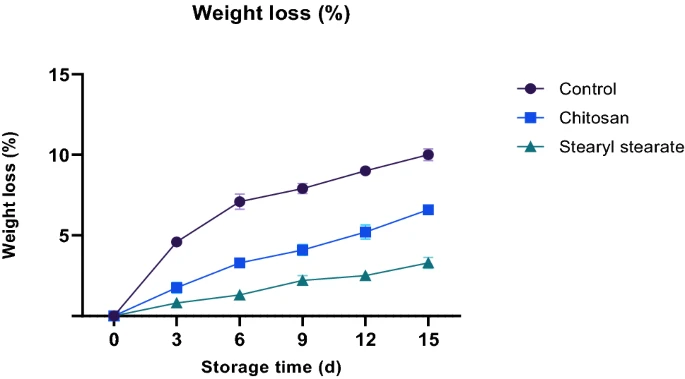

Weight loss of stored tomatoes. Image Credit: Soliman, H.A & Zahran. H.A., Scientific Reports

The Study

The focus of the current study in Scientific Reports is the development of a novel hydrophobic waxy thin film coating for fresh fruit preservation and quality assurance. The coating is prepared from stearyl stearate, which lacks an unsaturation center in its hydrocarbon chain. Buffalo fat was chosen as the natural material for the synthesis of the proposed film as it contains high levels of stearic acid.

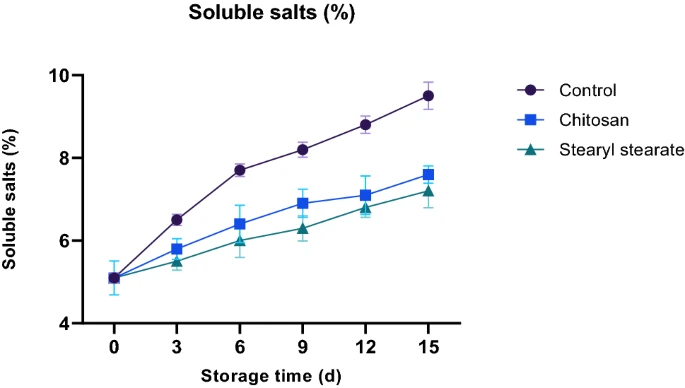

Tomatoes were selected as the target product for the study. The stearyl stearate-coated tomatoes were compared to tomatoes coated with chitosan. Over a fifteen-day period, the coated products were evaluated for firmness, pH, weight loss, concentrations of ascorbic acid, and soluble solids. Sensory evaluations were also carried out as well as acute oral toxicity lab tests on albino mice.

Dry rendering was used to extract fat from adipose tissue sourced from buffalo meat to prepare the stearyl stearate films. This process was carried out for three hours at 90 oC. Once cooled to 50 oC, a filtration method was applied, and the fat was stored at 5 oC until analysis. Elemental analysis, as well as spectral data, confirmed the chemical structure of the prepared stearyl stearate compound.

Quality parameters such as acid value, refractive index, iodine value, peroxide value, and determination of the compound’s content of unsaponifiable matter were determined and characterized. Additionally, oil hydrolysis and fatty acids concentration were analyzed and characterized. The authors performed analytical determinations and experiments three times, with the averages and standard deviations statistically analyzed.

Soluble salts % of stored tomatoes. Image Credit: Soliman, H.A & Zahran. H.A., Scientific Reports

Study Conclusions

Freshly harvested tomatoes are especially sensitive to fast spoiling. The prepared waxy, biodegradable, non-toxic, and sustainable buffalo fat-derived stearyl stearate thin film coating presented in the research was effective at delaying ripening and associated spoilage issues. By controlling water permeability through the fruit’s epidermis, the hydrophobic film can extend shelf life.

Physiological changes that would otherwise cause quality and shelf life issues can be controlled and mitigated using this novel thin film organic coating. In mouse-model toxicity tests, complete safety was demonstrated up to 25 g/kg by mouse weight. Due to the favorable results demonstrated in the paper, the authors have proposed that this thin film coating can be safely and effectively applied for the preservation of fast-spoiling food products.

Further Reading

Soliman, H.A & Zahran. H.A. (2022) Synthesis of a new hydrophobic coating film from stearic acid of buffalo fat Scientific Reports 12 article no: 18465 [online] nature.com. Available at: https://www.nature.com/articles/s41598-022-23003-4

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.