A paper recently published in the journal Energies reviewed the use of different organic waste as fuels in microbial fuel cells (MFCs) for bioenergy production.

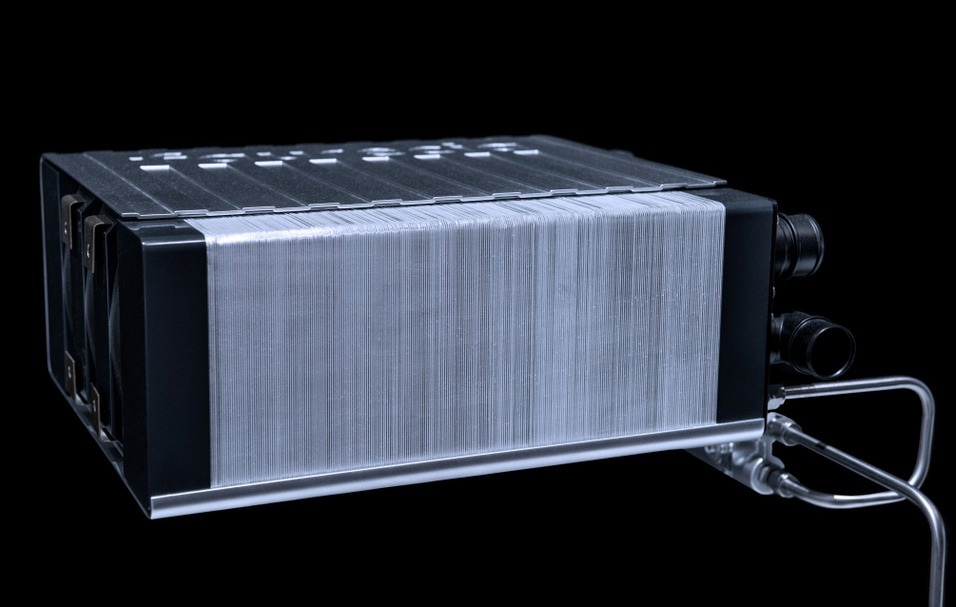

Study: Organic Waste Substrates for Bioenergy Production via Microbial Fuel Cells: A Key Point Review. Image Credit: Sergii Chernov/Shutterstock.com

Background

The growing consumption of energy across the world has increased concerns about the adverse impacts of the existing high-cost and less eco-friendly fossil fuel-based energy generation processes. MFCs used for bioenergy production represent an eco-friendlier and more economical alternative as they primarily use organic waste matter as fuels.

MFCs typically function as bio-electrochemical devices that use organic substrates to enable the enzyme cultures and/or electrogenic bacteria to generate electricity, which reduces the environmental hazardous value, such as chemical oxygen demand (COD), of the organic waste. An extensive range of by-products from several industries was evaluated as fuels in MFCs in several studies.

In this study, researchers reviewed multiple organic waste substrates that can be utilized as fuels in MFCs for the generation of bioenergy and the effect of their utilization in improving the Coulombic efficiency, COD removal efficiency, and power density.

Energy Generation Using Organic Waste as MFC Substrates

Vegetable, Fruit, Food Waste, and Wastewater

Food waste generated from restaurants and households is considered suitable for bioenergy production. Two-chamber MFCs are typically used for energy generation using food waste.

High Coulombic efficiency was realized when potato pulp and canteen waste leachate were used in single-chamber MFCs. The maximum volumetric power densities were achieved when potato pulp, natural vegetable waste, food waste leachate, food waste, and canteen waste were used in three-chamber and two-chamber MFCs, while the highest areal power densities were realized when culled tomatoes, potato, food processing waste, canteen waste leachate, canteen waste food, and food waste ethanol fermentation stillage were utilized as a fuel in single-chamber and two-chamber MFCs.

Seafood Industry

Waste generated from the seafood industry contains a high organic content, including nitrates, oils, and fats. Moreover, the industry also generates a significant amount of wastewater during equipment cleaning and seafood processing.

The highest volumetric power density was realized when seafood waste was used in a two-chamber MFC with a graphite rod as both cathode and anode, while the maximum areal power density was achieved when seafood waste was used in a two-chamber MFC with polypropylene as the cathode and anode.

Seafood waste in air-cathode MFC and single-chamber MFC with carbon cloth steel mesh as a cathode and anode led to the highest COD removal efficiency, while the maximum Coulombic efficiency was achieved when the waste was used in air cathode MFC.

Dairy Industry

The dairy industry acts as a leading source of wastewater that contains high content of vitamins, lipids, proteins, and lactose and several pollutants such as solids, chlorides, phosphates, sulfates, and nitrates.

The highest areal power density was achieved when yogurt was used as fuel in a single-chamber air cathode MFC with activated carbon as cathode and stainless-steel fiber felt as the anode, while the maximum volumetric power density was realized when dairy manure was utilized in a three-chamber MFC with graphite fiber brush and granules as cathode material and graphite fiber brush as anode material.

Dairy waste in a single-chamber MFC with graphite plate as both cathode and anode resulted in a maximum COD removal efficiency, while the highest Coulombic efficiency was realized when cheese whey was employed as fuel in single-chamber MFC with graphite fiber cloth as the cathode and graphite fiber brush as an anode.

Overall, the use of dairy wastewater in two-chamber MFCs led to better Coulombic efficiency and power density, whereas in single-chamber MFCs led to maximum COD removal.

Winery and Brewery Waste

Winery and brewery wastewater is rich in heavy metals, phosphorous, nitrate, carbohydrates, and sugars and considered to be a major source of bioenergy production. The highest areal and volumetric power density were achieved when winery waste and brewery waste were used in tubular and single-chamber MFCs, respectively.

Additionally, the use of brewery waste in single-chamber MFC resulted in a maximum COD removal efficiency, while the use of winery waste in tubular MFC led to the highest Coulombic efficiency. Overall, single-chamber MFCs led to the highest Coulombic efficiency, COD removal efficiency, or power density with different working volumes.

Oil Industry

Oil waste is primarily composed of nitrogen, sugars, lipids, and solids. The use of soybean oil as fuel in single-chamber MFC with carbon cloth/stainless steel as the cathode and graphite felt as the anode led to the highest COD removal efficiency and power density, while the maximum Coulombic efficiency was realized when vegetable oil effluent was used in dual-chamber MFC with carbon cloth as a cathode and graphite rod as an anode.

Animal and Meat Industry Waste

Rising demand for meat around the world has increased the waste generated from the meat industry. Typically, two-chamber MFCs are utilized to achieve the maximum power density, while the single-chamber MFCs generate the highest Coulombic efficiency from meat waste.

Additionally, the maximum COD removal is realized by a tubular MFC. The highest power density and COD removal efficiency were achieved when goat rumen fluid and slaughterhouse waste were used in four two-chamber MFC and MFC aerobic bioreactor, respectively. Slaughterhouse waste in MFC with air-breathing cathode led to maximum Coulombic efficiency.

Distillery and Sugar-Based Industries

Molasses is the major byproduct of sugar-based industries and is rich in salts and sugars, while wastewater containing solids is the primary byproduct of the distillery industry. The highest power density, COD removal efficiency, and Coulombic efficiency were realized when distillery waste, molasses, and alcohol distillery were utilized in single- and two-chamber MFCs, MFC with the membrane electrode assembly (HEM), and plate-type thermophilic MFC, respectively.

Agricultural and Soil Waste

Agricultural processes produce plant waste composed of lignin, hemicellulose, and cellulose, while soil waste is generated due to the accumulation of synthetic nitrogen, urine, urea, and other substances in the soil.

The maximum power density in agricultural waste and soil waste was achieved when cellulose and human urine were used as fuel in single-chamber membrane-less MFC and soil-based MFC, respectively.

Additionally, the highest COD removal efficiency and Coulombic efficiency were realized when starch wastewater and rice straw powder were used in air-cathode MFC and 3 in a series H-type two-chamber MFC, respectively.

Municipal/Solid Waste—Mixed Waste

Municipal waste is a major source of energy generation in different types of MFCs. Vegetable waste with molasses in six U-shaped dual-chamber MFCs led to the highest power density, while municipal or agro or diary wastewater in two-chamber MFCs led to maximum COD removal efficiency. The highest Coulombic efficiency was achieved when sludge and potato were used in eleven two-chamber MFCs.

Conclusion and Future Outlook

Treated food waste is the most suitable organic waste substrate for MFCs among the various types of waste reviewed in this study, followed by dairy, brewery, and animal waste, due to their continuous availability. Additionally, a substantial increase in the use of food waste as fuel in MFCs can significantly increase power densities.

However, the identification of a suitable cathode electrode material is one of the notable challenges of MFCs, which must be resolved to achieve enhanced energy efficiency in MFCs. Moreover, several other factors, such as diffusion of substrates into the biofilm and microbial growth, must be investigated for all kinds of waste for improved bioenergy generation. Although MFCs are currently a nascent technology, upscaled MFC systems, and their sustainability will play a crucial role for future generations.

More from AZoM: ICP-MS for Trace Metal Analysis

Source

Mamma, D., Sourkouni, G., Argirusis, C. et al. Organic Waste Substrates for Bioenergy Production via Microbial Fuel Cells: A Key Point Review. Energies 2022. https://doi.org/10.3390/en15155616

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.