Software-supported camera-based image evaluation offers numerous benefits, including the early detection of defects and irregularities in a range of production processes. When used appropriately, this image data has the potential to contribute to zero-defect production targets.

Early defect detection is a key component in robust overall quality assurance and a central driver in state-of-the-art camera technology, becoming a standard feature of a range of production lines.

Image Credit: IDS Imaging Development Systems GmbH

The primary goal of the majority of production lines is to work towards zero-defect production, ensuring this is reached as closely as possible.

Towards Zero-defect Production Using 3D Camera Technology

Ongoing improvements in process and product quality have led to near-constant changes and evolutions in manufacturing procedures. Driven by the pressure to save time and money, manufacturers continue to invest resources and energy into automating test steps, aiming to improve throughput while minimizing waste.

Meeting these objectives necessitates the use of machines - there is no way that humans will achieve these objectives otherwise.

As automation becomes central to increasing numbers of quality assurance functions, vital yet cost- and time-intensive lab tests are gradually being superseded by in-line and shop floor product inspections.

Many of these inspections rely on modern camera technology to always maintain an overview of test objects and their properties. This technology can be installed in almost any location as production progresses and can be utilized without the need to actively intervene with the production process.

When used in conjunction with image processing technologies, the use of camera images provides a number of notable advantages and usage options. Optical measurement and test procedures facilitate incredibly fast, wear-free, quality testing options during the manufacturing process.

Standard barcode readers are able to read the content of a code, but industrial cameras offer the ability to read the content of the code, determine and evaluate the item’s color, quality, size, alignment, surroundings and other key parameters.

This expanded functionality extends test capabilities and improves test quality while simultaneously improving the potential for further automation of quality assurance.

The use of camera-based systems allows for the early detection of defects, often long before these lead to irreparable after-effects and the loss of production batches.

Successfully implementing camera technology to help make autonomous decisions requires the selection of instrumentation able to adhere to the rigorous standards of the measurement and test equipment required.

It should be kept in mind that this technology’s core role is to provide humans with the best possible support, potentially ultimately replacing them entirely.

With 3D image processing, the flexibility and accuracy of measurement and test processes can be improved immensely.

Dr. Martin Hennemann, Product Manager for ENSENSO, IDS

Contemporary 3D camera technology empowers robots to actively analyze their environment, providing them with the necessary information to autonomously respond to various situations.

This data allows robots to monitor the dimensions and position of objects on the shop floor, as well as enabling the exact conclusions to be drawn around imperfections or deviations based on comparisons with reference objects.

These applications are employed as part of in-line inspections to confirm that correct product components are assembled.

The automotive industry is particularly error-prone due to typical production processes involving large numbers of variants. Customers will frequently customize vehicles according to individual specifications and preferences, for example, opting to purchase specific tires, engine variants, chassis or interior features.

Production personnel working in these organizations can see considerable benefits from automated systems being able to alert them before an incorrect or defective part is installed.

This additional layer of quality assurance reduces the labor and time needed for post-production inspections and also reduces the risk of errors which can lead to production downtime.

The high degree of individualization in the configuration of cars inevitably results in an immense range of variants, which is practically impossible to manage and check without the assistance of camera technology.

Dr. Martin Hennemann, Product Manager for ENSENSO, IDS

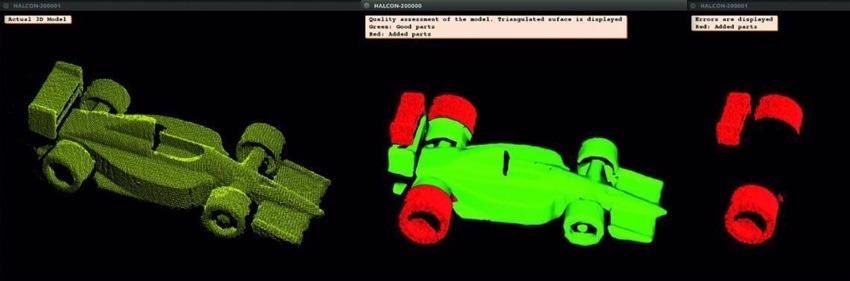

With HALCON 3D image processing, even the tiniest differences between the object and the reference model can be detected. Image: Demo by IDS, Control, captured with an Ensenso 3D stereovision camera. Image Credit: IDS Imaging Development Systems GmbH

HALCON 3D image processing allows for the detection of even the most minute differences between an object and its associated reference model.

IDS recently demonstrated an instance of 3D object verification at the Control international trade fair for quality assurance which took place in Stuttgart. This demo system had been designed to reconstruct objects via an Ensenso N35 3D camera prior to using HALCON image processing to perform a data comparison.

The range of 3D data generated was evaluated against a reference model, allowing the detection of any imperfections or deviations. Using 3D image processing, it was possible to identify irregularities in test objects invisible to the human eye.

By employing this technology, it is possible to significantly improve the quality of manufactured objects during subsequent process steps, achieving this through the use of ultra-high precision digitization via Ensenso 3D cameras and image processing to enable object verification.

3D complements 2D camera technology. Each technology has its own advantages. The combination of 2D and 3D performs the tasks of today and tomorrow while effectively minimizing production errors.

Dr. Martin Hennemann, Product Manager for ENSENSO, IDS

Three-dimensional imaging technology provides a highly beneficial add-on to 2D camera technology, and these two approaches can be used to perform an ever-expanding range of functions when utilized in conjunction with one another.

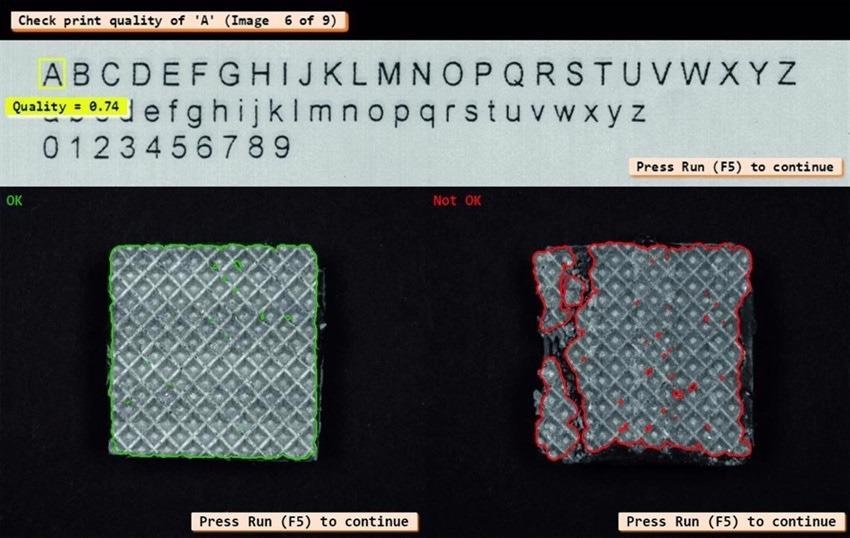

Each of these individual technologies offers specific advantages for certain applications: analysis of 3D data allows the determination of shapes, surface structures or the position of objects in a space. At the same time, 2D data enables the precise detection of edges, colors and markings.

Three-dimensional imaging data was used to perform an object comparison as part of the IDS 2018 Control demo.

Where part codes were present, these could be decoded and identified using 2D camera images.

This approach is commonly used by car manufacturers, who utilize camera-based inspection methods and combined 3D and 2D technology to facilitate final product inspections. Clearance dimensions are acquired on a finished car body to precisely measure or test these against specifications.

For text recognition (OCR) and edge detection, classic 2D image material is the best source material for image processing. Image Credit: MVTec HALCON.

Camera technology offers considerable potential in supporting manufacturers' work towards the ideal of zero-defect production. To minimize production errors, it may be necessary to use 2D or 3D technology or a combination of the two. The choice of approach is highly dependent on what is being tested.

Camera systems offer a number of benefits when used to support manual manufacturing processes. These can be utilized to monitor workflows at manual workstations, as image evaluation confirms that the operator has selected the correct parts, completed all required production steps or fitted the appropriate number of screws to a part.

In these scenarios, a downstream system may also be used to confirm that operations have been performed correctly, highlighting any potential errors via audible or visual alerts. This additional quality assurance step can prove essential to final product quality.

Camera and production technologies continue to evolve, but it should be noted the development of a new camera technology does not immediately render existing technologies obsolete.

There have been significant advances in 3D technology in recent years, and this is now able to display various object features, a development that has led to new application viability and the potential for 3D technology to serve as a useful add-on to 2D camera technology without entirely replacing this.

Cameras themselves have progressed from simple image delivery machines to smart, adaptable image processing solutions.

This robust combination of sensors, camera, communication capacity, intelligence and adaptability has resulted in machine-vision systems that are able to match the functionality of 2D and 3D cameras while also contributing to the prevention of errors in a meaningful way.

Perfect production with no defects or need for reworking remains the ideal aspiration, and while this goal is not realistically attainable, investment into the latest camera and evaluation technology can provide an invaluable tool for any organization working towards zero-defect production.

This information has been sourced, reviewed and adapted from materials provided by IDS Imaging Development Systems GmbH.

For more information on this source, please visit IDS Imaging Development Systems GmbH.