Raith’s ELPHY MultiBeam establishes a new commercial standard for SEM and FIB-SEM nanolithography solutions. It combines the latest technology for 3D ion beam based nanofabrication and other 3D nanofabrication techniques with the excellent EBL performance, and helps to unlock the total nanofabrication potential of a SEM, FIB-SEM or HIM system.

The ELPHY MultiBeam includes comprehensive multiple method nanopatterning functionality in a single tool for Electron Beam Lithography (EBL), Focused Ion Beam Nanofabrication, Etching and Deposition, Helium Ion Beam Patterning and Gas assisted Focused Electron Beam Induced Processing (FEBIP).

ELPHY MultiBeam Product Details

Main Applications

- SEM lithography

- (3D) rapid nano prototyping

- Nanolithography

- FIB-SEM nanolithography and nanopatterning

- Helium Ion Microscopy - HIM - lithography

Attachment

- Attach to analytical SEM, FIB-SEM, or HIM supplier instrumentation

Stage

- Depends on analytical FIB-SEM, SEM, or HIM supplier

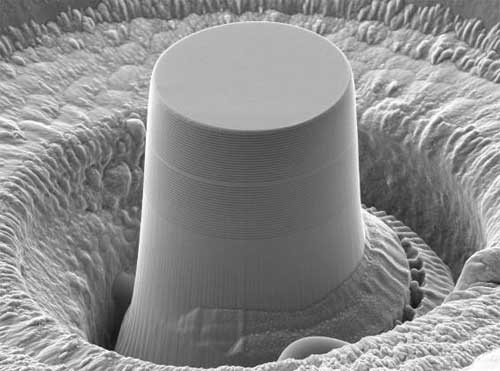

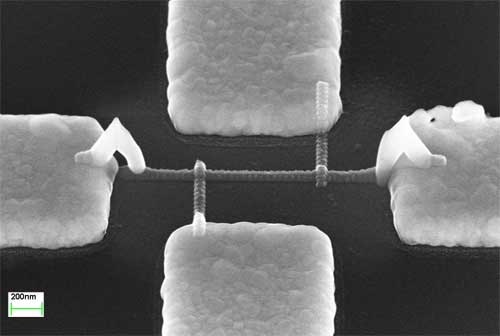

Nanolithography “pen” – ELPHY turns your SEM or FIB-SEM into a nanofabrication system. Image credit: Raith

Undreamt-of Possibilities

- Free of charge global support infrastructure for a broad range of nanofabrication and nanolithography applications

- Full on-site system installation and training

- Flexible upgrade (trade-in) concept with access to the whole Raith product line

- Maximum-speed 20 MHz dual DAC addressing for X and Y main beam deflection (16 bit) with low noise differential outputs

- True multi user management by user authentication and related specific system parameter administration; Users find their system as they have left it

- Separate thermo-stabilized and RF-shielded 19” electronic unit with DSP technology supplying ultimate performance regarding maximum precision, lowest noise and long term stability enabling complex applications

- Accurate six additional multiplying 16-bit DACs for multilevel lithography, maximum precision overlay alignment, and write field calibration with sub-nm step size control

- Multi I/O Signal Router with touch screen display for simple automatic or manual signal switching between ELPHY and other auxiliaries sharing same external scan input as EDX/WDX/…

- FLEXposure directional scanning modes, flexible patterning attributes manager, recipe manager and GDSII patterning-on-image (POI) functionality

- Easy to use, fully integrated Raith NanoSuite software

- Dedicated NanoPECS Proximity Effect Correction and advanced 3D-Lithography software modules, calibration standards, test samples, starter kits and additional accessories available

Relying on Field Proven Technology and Being Prepared for the Future

The ELPHY nanolithography and nanofabrication upgrade kits are the perfect, most flexible and cost-effective solution for entering the Electron and Ion Beam Lithography domain by speeding up FIB-SEM, SEM, and HIM. With a track record of about ~1000 installations, ELPHY is the most widely distributed SEM/FIB lithography attachment in the market. Raith Nanosuite software is combined into ELPHY as well as into full Raith systems, process compatibility is maintained and upgrading made simple.

ELPHY MultiBeam Applications

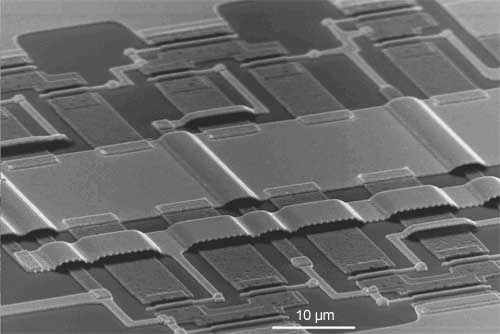

- DEMUX device - J. Degenhardt, University of Duisburg, Germany

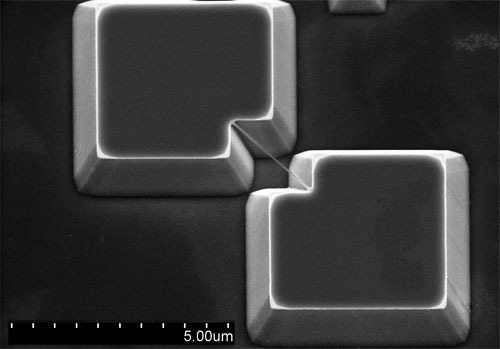

- Quantum effect device - A. Nadzeyka, customer demo Raith @ Zeiss

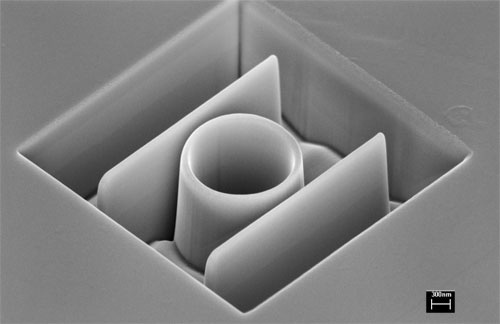

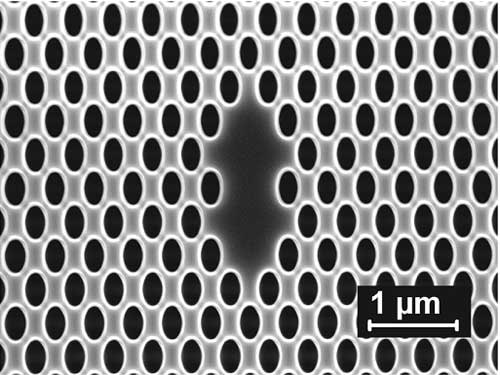

- Inner part of photonic crystal with defect

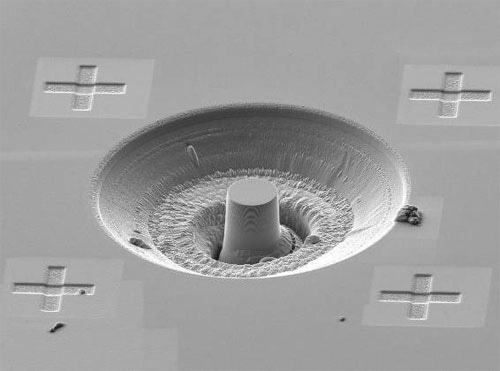

- Nano mechanical resonator for sensing applications - M.Ali, UAlberta, CA

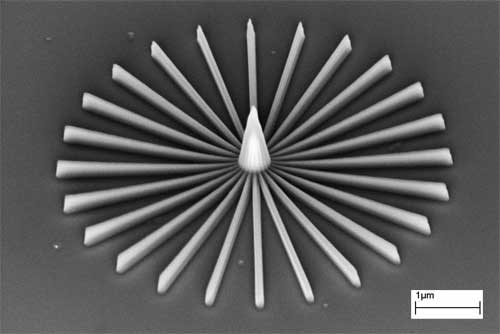

- Prototyping of optical resonators - F. Pérez-Willard

- Insulator deposition for growth rate studies - S. Bauerdick, Raith GmbH

- Conductive 3D deposition for optimized contact resistance - S. Bauerdick, G. Piaszenski, Raith GmbH

- Prototyping of optical resonators - F. Pérez-Willard