High efficiency makes all the difference: it is essential for heat exchangers to transmit heat or cold as efficiently as possible – and the connection elements, in particular, play a significant role in that process. Thus, the induction brazing of the components is a vital part of the process in heat exchanger assembly. Generators from eldec act as an efficient source of energy.

Induction Brazing with Eldec; More Reproducible, Faster, and More Reliable

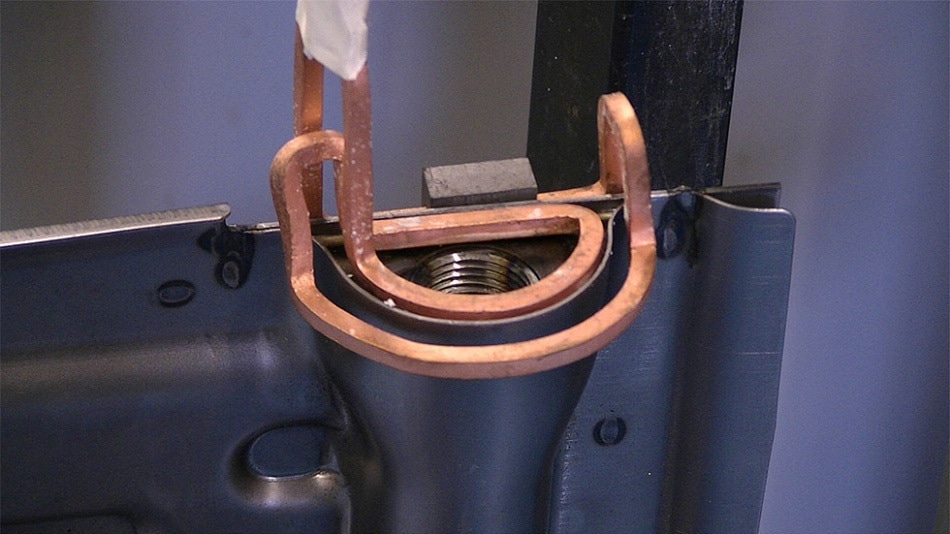

Heat exchangers are employed in a wide range of applications that include energy supply, power plant construction, and machinery manufacture. Usually, induction brazing with a phosphorus brazing alloy is the preferred technique. This enables the brazed connection to be extremely secure. Additionally, the alloy fills the joint between the connection element and the heat exchanger in a reliable manner.

Many users prefer to use a flame for these brazing processes, but this process is extremely slow. In addition, it is not possible to precisely control the temperature, which results in variable brazing quality. Induction heating, by contrast, is faster, more reliable, and more reproducible, as demonstrated by the induction brazing shown here using a phosphorus alloy.

An eldec medium-frequency generator with 15 kW power output was used as the energy source. The user benefits from a technology that makes it possible to control its energy supply within a few percent. It takes only a few seconds to complete the whole process. This indeed increases the reliability of the brazing process to a considerable extent. Additionally, the high efficiency of the eldec generator reduces the overall energy consumption.

Heat exchanger connection element

Induction brazing enables high processing quality and reproducibility

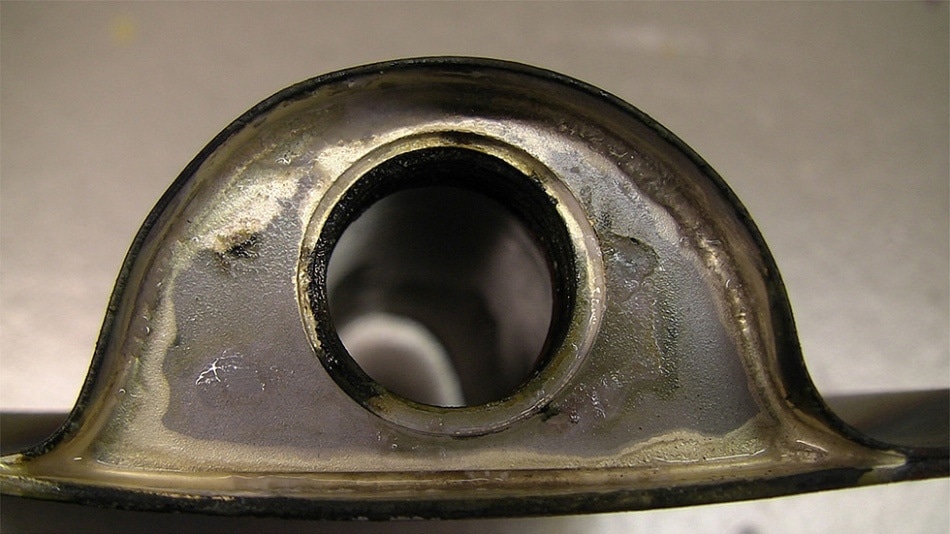

Heat exchanger components, fast and safe due to induction brazing by eldec

Brazing heat exchangers

Benefits

- High device protection

- High process speed

- Easy handling and operation

- Maintenance-free generator technology

- Reproducible brazing processes

Relevant Generators

This information has been sourced, reviewed and adapted from materials provided by Eldec Induction USA, Inc.

For more information on this source, please visit Eldec Induction USA, Inc.