Inhalation anesthetics for animals are potentially toxic when breathed in by humans, so these must be carefully monitored when in use.

The inhalation anesthetic isoflurane is used with animals, in particular cats, dogs and mice. Isoflurane is a liquid at room temperature and is commonly vaporized in a controlled manner in an oxygen stream. Using half-closed rebreathing systems, evaporator gas flows within the range of 1 L/min are mixed with isoflurane volume fractions of 1.5 to 3% by volume.

Because of isoflurane’s considerable volatility, high levels of workplace exposure can occur during use, with recommended maximum occupational exposure in the range of 10-50 ppm, for an assumed working time of 8 hours.

FTIR (Fourier Transform Infrared) spectroscopy is a respected and recognized method used in the discovery and quantification of gaseous compounds. It is therefore suited for use for the monitoring of toxic gases within a wide range of workplaces.

Instrumentation

The Bruker MATRIX-MG5 FTIR gas analyzer (Figure 1) can work alongside the calibration-free control software OPUS GA and a comprehensive library of high-resolution gas phase spectra, enabling the concentration of isoflurane to be determined with a sub-ppm sensitivity.

Using the MATRIX-MG5, users do not need to possess expert knowledge in FTIR gas analysis to effectively monitor isoflurane in their workplaces.

Figure 1. Bruker Optics MATRIX-MG5 spectrometer with heatable gas cell of 5 m optical path length. Image Credit: Bruker Optics

The MATRIX-MG5 gas analyzer features:

- Rapid, continuous, fully automated identification and quantification of gas compositions

- Exceptional sensitivity, enabling the detection of traces of gas compounds from a few parts per billion up to one hundred percent

- Features a calibration-free easy-to-use and flexible software package - OPUS GA – which includes automatic compensation for atmospheric and other interfering gases.

- An available spectral library of more than 300 gas compounds

- Easy maintenance and operation

- Design based on the RockSolid™ interferometer for insensitivity to vibrations and permanently aligned optics

- Includes a temperature-controlled gas cell (up to 191 °C)

- Can account for variable gas temperature and pressure thanks to included sensors inside the gas cell

- Detection limit of 20 ppb

Experiment

A single self-measured quantitative reference spectrum of isoflurane was employed to develop an analysis method, allowing the OPUS GA analysis software to successfully quantify isoflurane using the MATRIX-MG5.

A detection limit of approximately 20 ppb isoflurane was determined from measurements in ambient air at 40% relative humidity and 25 °C room temperature. This measurement is three orders of magnitude less than the guidelines’ maximum occupational limits for working environments.

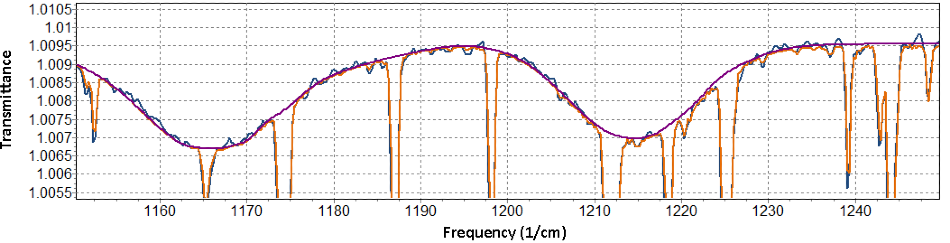

Figure 2 displays the measured spectral fingerprint of 100 ppb isoflurane, overlapped by the infrared signals of ambient water vapor. An accurate quantification of isoflurane was established, even despite significant cross-sensitivity with water vapor.

Figure 2. Measurement (blue) and model fit (orange) to quantify the amount of isoflurane. Also, the contribution of the interfering water vapor is automatically considered in the fitting routine of OPUS GA such that the measurement and the result of the fitting procedure show an excellent agreement. The infrared signal of 100 ppb isoflurane is displayed in purple. Image Credit: Bruker Optics

Determination of the Amount of Substance

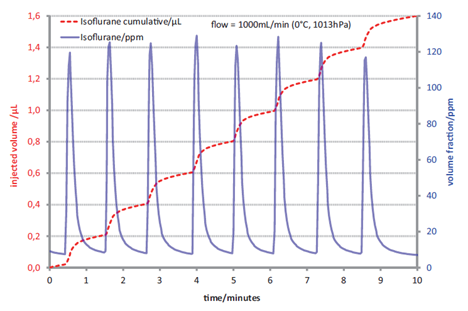

Should the carrier gas flow be satisfactorily known, FTIR analysis values can be integrated in time to reveal a total amount of substance. The result’s accuracy allows a statement about the accuracy of FTIR analysis values.

In this particular experiment, multiple defined volumes of 0.2 μL of isoflurane were injected into a defined airflow using a syringe pump. The carrier gas flow (dry air) was then monitored using mass flow controllers.

Here, integrated FTIR analysis values revealed an impressive accuracy in the range of 2 to 4% (Figure 3). These values are considered to be comfortably within the expected confidence interval, factoring in the accuracy of the measurement of gas flows using mass flow controllers, as well as the deviations attributed to FTIR gas analysis and this particular experimental setup (for example, faulty injection or leakage currents).

Figure 3. Measured volume fractions of isoflurane (blue, right ordinate) and derived quantities (red, left ordinate). Injected volumes: 8 × 0.2 μL= 1.6 μL at 1000 sccm. Image Credit: Bruker Optics

Summary

The MATRIX-MG5 FTIR gas analyzer offers outstanding sensitivity, making it a valuable instrument well suited to the identification and quantification of the smallest traces of toxic gas compounds in ambient air.

The OPUS GA control software allows users to conduct these measurements at the push of a button, with no need for expert knowledge or extensive training. The software also provides a convenient interface to various industrial communication protocols.

FTIR gas analysis also has great potential for use in other scientific fields; for example, exhaust gas analysis in automobile industry, impurity measurements in pure gases, scientific research and the analysis of catalytic reactions.

This information has been sourced, reviewed and adapted from materials provided by Bruker Optics.

For more information on this source, please visit Bruker Optics.