In this interview, Chuck Hagyard, EV Business Development Manager at Cincinnati Test Systems, talks about the importance of testing electric vehicle battery trays.

To begin, can you give us an introduction into Electric Vehicle Battery trays?

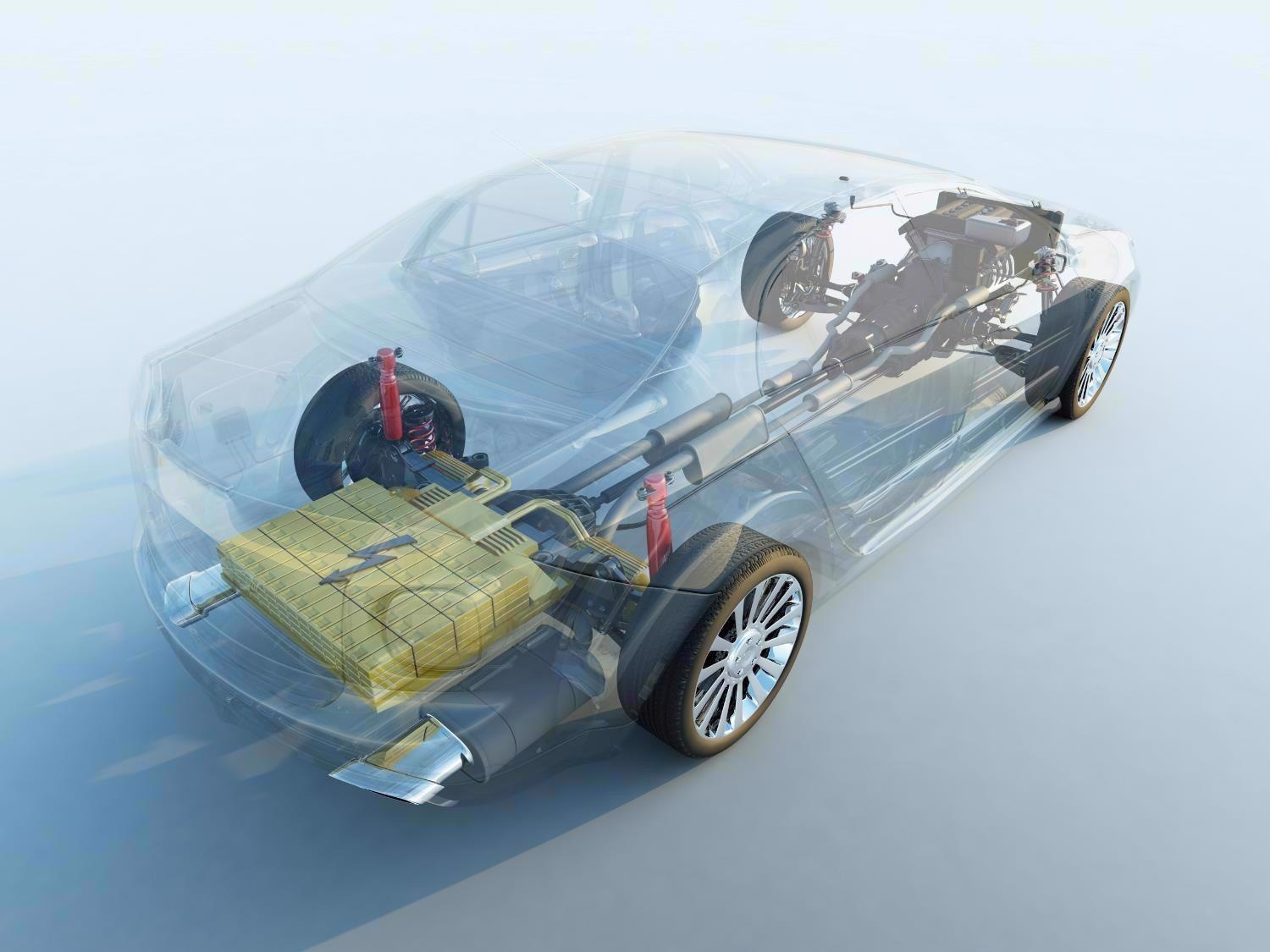

Electric Vehicle (EV) Battery Trays constitute the structural element of the modern-day EV Battery System. Battery Trays are designed to provide structural integrity to the Battery Pack while also being sealed to prevent fluid ingress into the Battery Pack.

The Battery Trays being produced today are delicately balancing weight and structural integrity through the use of innovative materials and processes to provide adequate structural rigidity. Rigidity is critical, but reducing weight is also a key consideration as it can significantly impact the range of the electric vehicle.

How important is the Electric Vehicle Battery trays in terms of the battery (and EVs) performance/efficiency?

The material and construction of the Battery Tray can have a significant influence on the efficiency of an electric vehicle. Reducing overall curb weight is essential to extend the range to a point where consumers will no longer experience range anxiety that has been one of the factors hindering the adoption of electric vehicles.

A balance must be struck between reducing weight while not compromising on the structural integrity of the Battery Pack. Cast aluminum and highly rigid composite materials are being introduced that maintain structural integrity while minimizing the electric vehicle's actual curb weight.

What are some of the adverse effects that can come from an inefficient Electric Vehicle Battery tray?

Suppose the proper balance between structural integrity and weight is not found. In that case, range anxiety will continue to be a factor that could potentially dissuade possible EV buyers from taking that leap and fully embracing the full-scale implementation of EV technologies. It's also essential for the Battery Trays to be designed so that they're robust and not subject to fluid ingress, which could result in a catastrophic failure of the Battery Pack system and, ultimately, the EV.

What is the Electric Vehicle Battery tray testing?

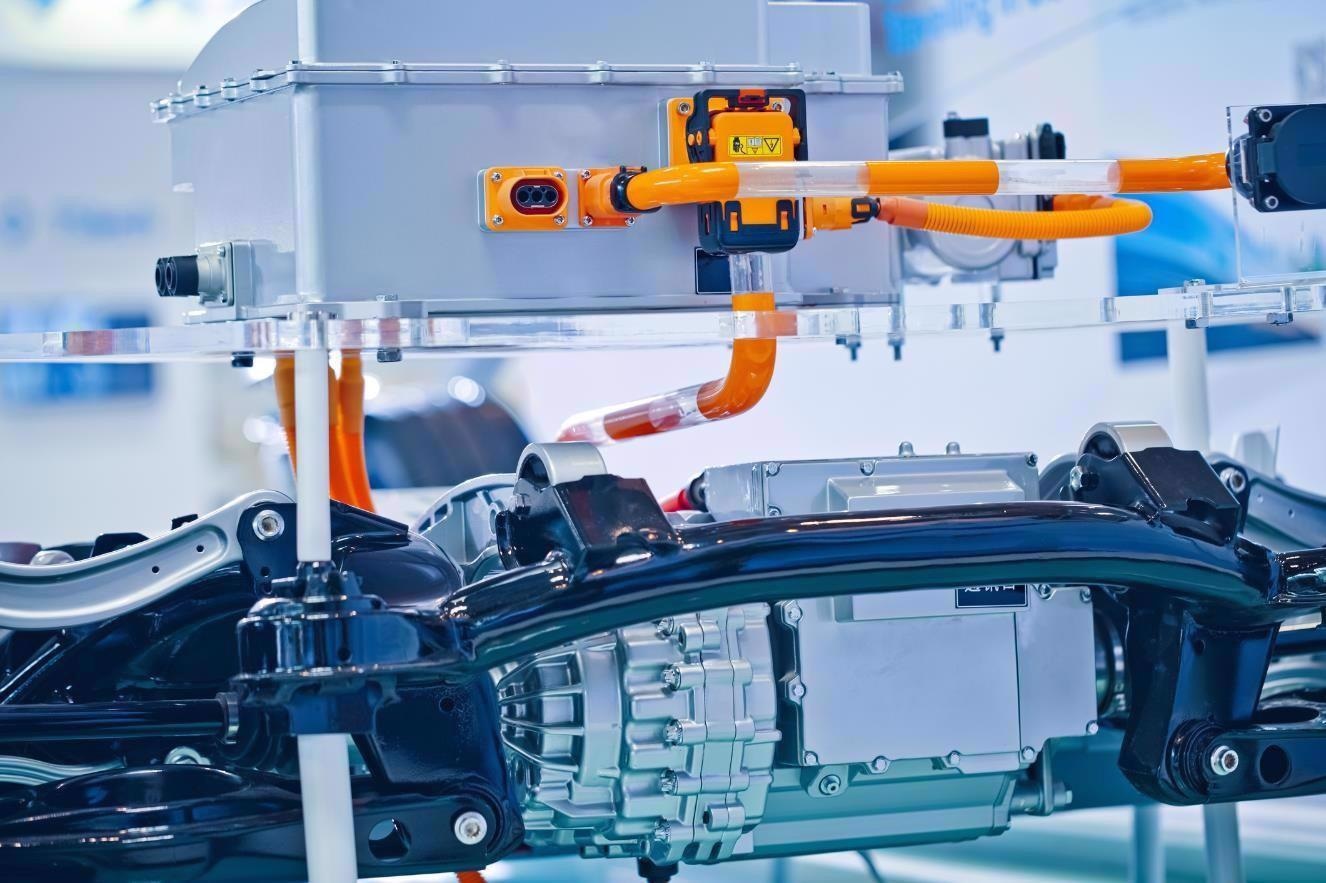

Electric Vehicle Battery Tray Testing is a crucial element in the manufacturing process. Manufacturers need to develop a robust and reliable product, and the leak test process becomes an essential means of verifying the integrity of the product and, ultimately, the manufacturing process.

The implications of selecting the wrong leak test method could have far-reaching consequences. Fluid ingress into the Battery Pack could be catastrophic to the vehicle, so the worlds of product design and manufacturing must converge to select the most appropriate test method to ensure the Electric Vehicle's long-term integrity.

What is the importance of this?

The implications of fluid intrusion into the Battery Pack are potentially devastating. The Lithium-Ion batteries powering today's EV's react negatively to the presence of fluid. In the most extreme cases, vehicles have caught on fire as a result of fluid ingress.

What would you say are some of the most significant challenges associated with Electric Vehicle Battery trays (and testing), and how can this be overcome?

Without question, the sheer size and the construction of the Battery Tray make it an extremely difficult leak test application. In addition to the Battery Tray's size and construction, the upstream manufacturing processes prior to the leak test play a very important role in the ultimate robustness of the test method. For example, processes that create heat, like a welding operation, could make the pressure or flow test method impractical.

In cases where the volumes are large, parts may flex, and temperature may be unstable, a pressure/flow-based measurement technique may not be suitable. In these cases, a tracer gas technology may be required to provide a robust and reliable test method.

Can you give us an introduction to Cincinnati Test Systems?

Since 1981 Cincinnati Test Systems has become a world leader in leak and functional testing for an extensive range of applications across every conceivable vertical market. With nearly 40 years of experience providing solutions, Cincinnati Test System's business has continued to grow.

Cincinnati Test Systems remains keenly focused on fueling its' growth through rigorous adherence to a multi-year technology development plan geared toward ensuring that we stay in a leadership position from both a product and test technology perspective. Constant innovation is the cornerstone of the Cincinnati Test System's growth plans.

What solutions do Cincinnati Test Systems offer in terms of tray testing?

Cincinnati Test Systems offers a full range of Battery Tray test solutions ranging from pressure/flow-based systems to more precise, tracer gas methods. The application requirements and manufacturing process-related concerns must be considered carefully when selecting the optimal test method. Cincinnati Test Systems stands apart from the competition because we can offer a solution for any test application based on having a complete toolbox of test solutions.

What is the current Electric Vehicle Battery tray testing market like, and how does Cincinnati Test Systems differ from other available options?

The Battery Tray test market is very diverse, with a multitude of companies offering different solutions. Cincinnati Test Systems is different from our competitors because we are not limited to any single test method or solution.

The overwhelming number of companies in the industry have a much narrower range of solutions and test expertise that they can leverage. Cincinnati Test Systems is different because we have a diverse tool kit of solutions ranging from pressure/flow-based options and tracer gas solutions.

The Battery Tray test is one of the most technically challenging applications in the Electric Vehicle test world. The most successful companies can be wholly objective and let the application requirements dictate which test method is best suited for the application. In this regard, Cincinnati Test Systems stands out among our peers in the industry.

https://www.youtube.com/watch?v=yoO-b0g277E

About Chuck Hagyard

I'm tasked with coordinating the EV Business Development activities for Cincinnati Test Systems in my current role. Over the past 28 years living and working in Detroit, I have been very fortunate to have gained significant insights into how the automotive industry functions. The insights gained and the relationships built have allowed me the great opportunity to marry the unique capabilities of Cincinnati Test Systems with the evolving needs the automotive industry is experiencing with EV technology coming to the forefront.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.