Avantes Offers Truly Unsurpassed Inter-Instrument Reproducibility and Production Scalability

The photonics market has grown exponentially over the past few years. More and more frequently, researchers, companies, and Original Equipment Manufacturers have begun to widely recognize the benefits of applying photonics.

This has been the case for the European Commission, which recognizes photonics as a key enabling technology of the 21st century.

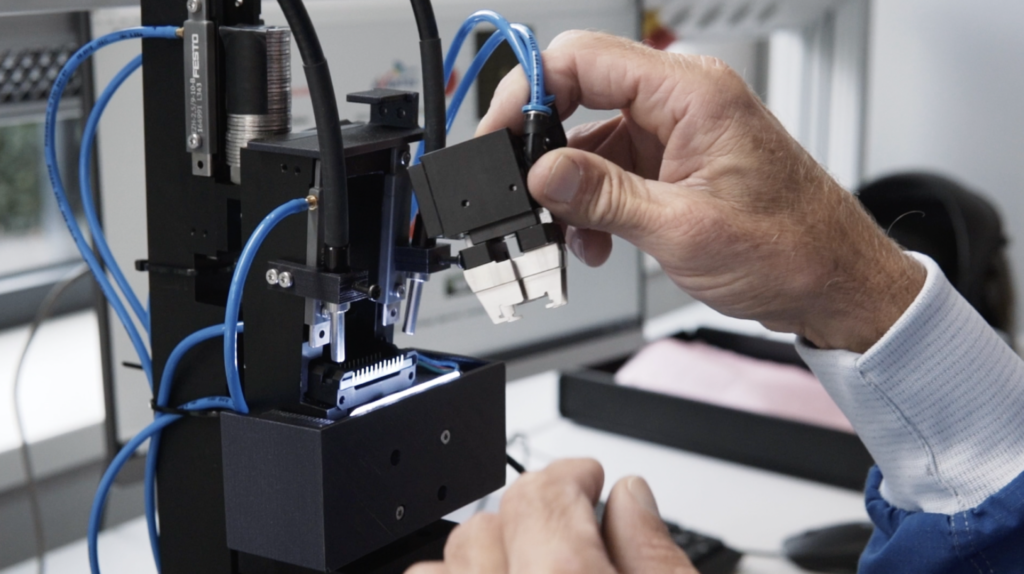

This has come as no surprise to Product Manager Ger Loop, who commented: “Spectroscopy is an amazing technique which can be applied in many markets and industries. We see that reflected in the increasing number of spectrometers we produce each year. That is one of the reasons we upgraded our manufacturing process to be completely future-proof. We go from manual production to automated manufacturing, or, as we like to call it, ‘AvaMation’.”

AvaMation: About the Company

Today, there is an ever-growing global demand for spectrometers. Increasingly, customers purchase in bulk, so consistency is essential: each spectrometer’s performance must be exactly the same. Ger explains: “When a customer integrates a spectrometer in-line at their production facility, they naturally want the same performance at a facility in another location.”

Historically our spectrometers are assembled by hand with great precision and expertise, but we are now able to automate a large part of this process. This way of manufacturing provides unsurpassed inter-instrument reproducibility and scalability in production. We decided to innovate this process to increase our efficiency and precision. We are now ready for a future with an increasing demand of spectrometers.

Ger Loop, Product Manager

What are the Perks for the Customer?

The new method of manufacturing benefits not only Avantes - in terms of the company’s efficiency - but also offers its customers a huge range of benefits. These include:

Manufacturing Capabilities that are Highly Scalable

AvaMation allows Avantes to be flexible when it comes to order customization, from small orders all the way up to high-volume orders.

Excellent Inter-Instrument Reproducibility

AvaMation allows Avantes to rapidly improve their quality assurance, as well as offer a greater degree of speed and manufacturing precision for the end customer.

Enabling Data Analysis

Avantes can continue to improve product lines and innovate as a result of collecting data from the manufacturing process.

Image Credit: Avantes BV

Invest in the Future

Avantes have other plans in addition to developing a future-proof airtight manufacturing process.

Ger shares: “We continuously invest in the future company-wide, not only when it comes to our manufacturing. Innovating, together with our customers, is an important belief within our company. That’s why we invest in in-house application know-how. Our sales team, for example, exists of engineers and physicists with specific market knowledge. Thanks to all this in-house knowledge, we can optimally guide and serve our customers with their application challenges”.

Avantes are passionate about their partnership approach, which Ger believes allows the company to tailor their solutions to meet the end user’s needs.

Of course, we deliver our carefully picked portfolio products, but we can go the extra mile. We are passionate about the success of our customers. That’s why we follow a discovery journey with spectrometer integrating customers to ensure we create their most suitable setup together. After that process, our engineers and support team work collaboratively to ensure successful integration and maximum interoperability. A valuable asset of Avantes in my opinion, which will only grow stronger now we changed to automated manufacturing.

Ger Loop, Product Manager

Keen to Read More About Avantes or AvaMation?

If you’d like to know more about Avantes, AvaMation, Avantes’ product range or vision on the future of spectroscopy, simply contact the team.

This information has been sourced, reviewed and adapted from materials provided by Avantes BV.

For more information on this source, please visit Avantes BV.