At JEC World in April 2023, AZoM sat down with Alexander Weis from Hunstman to discuss their award-winning composite and adhesive products.

Please could you introduce yourself and your role at Huntsman?

My name is Alexander Weis, and I'm the European strategic marketing manager for our adhesives in Huntsman’s Advanced Materials division. In my role, I work closely with our technical R&D and operational marketing teams to lead the commercialization of Huntsman innovations.

In addition, it's also my task to identify trends and understand future market needs for our customers and see how we can develop our innovation pipeline.

Huntsman has three divisions spanning polyurethanes, advanced materials, and performance products. Which divisions, if not all, are represented at JEC World?

The show is mainly for advanced materials, where we focus on composites and adhesives.

Our polyurethane division also attends, focusing on some applications that are related to their PU materials, for example, for interior parts used in automotive transportation and e-mobility applications.

What industries do your technologies mainly target?

For our adhesives, especially in the area in which I'm working, we are heavily focused on the transportation industry, which for us includes buses, trucks, marine, and rail. In the transport industry, you need tough structural adhesives that perform over many, many years in challenging applications, conditions, and climates.

And then, of course, you have the big haystack of general industrial applications, which is by far the largest segment for adhesives.

For our composite materials, lightweighting is still a big trend in the industry for energy and fuel savings, and these materials are a vital part of those industries. Whether they are used on the outer structures or on the interior parts, everything needs to be lighter and cleverly designed, and composites play a big role in that.

How important is sustainability to the different divisions of Huntsman?

For Huntsman as a company, sustainability is one of the most important topics of all because, in the end, whatever we do needs to serve the needs of our customers. That means we need to have the right modern materials to enable our customers’ sustainability goals. It's all about replacing old inefficient materials with new modern materials that are really making a difference, and that's a vital part of our strategy. It's up to us to understand what customers need in the future and develop those new materials.

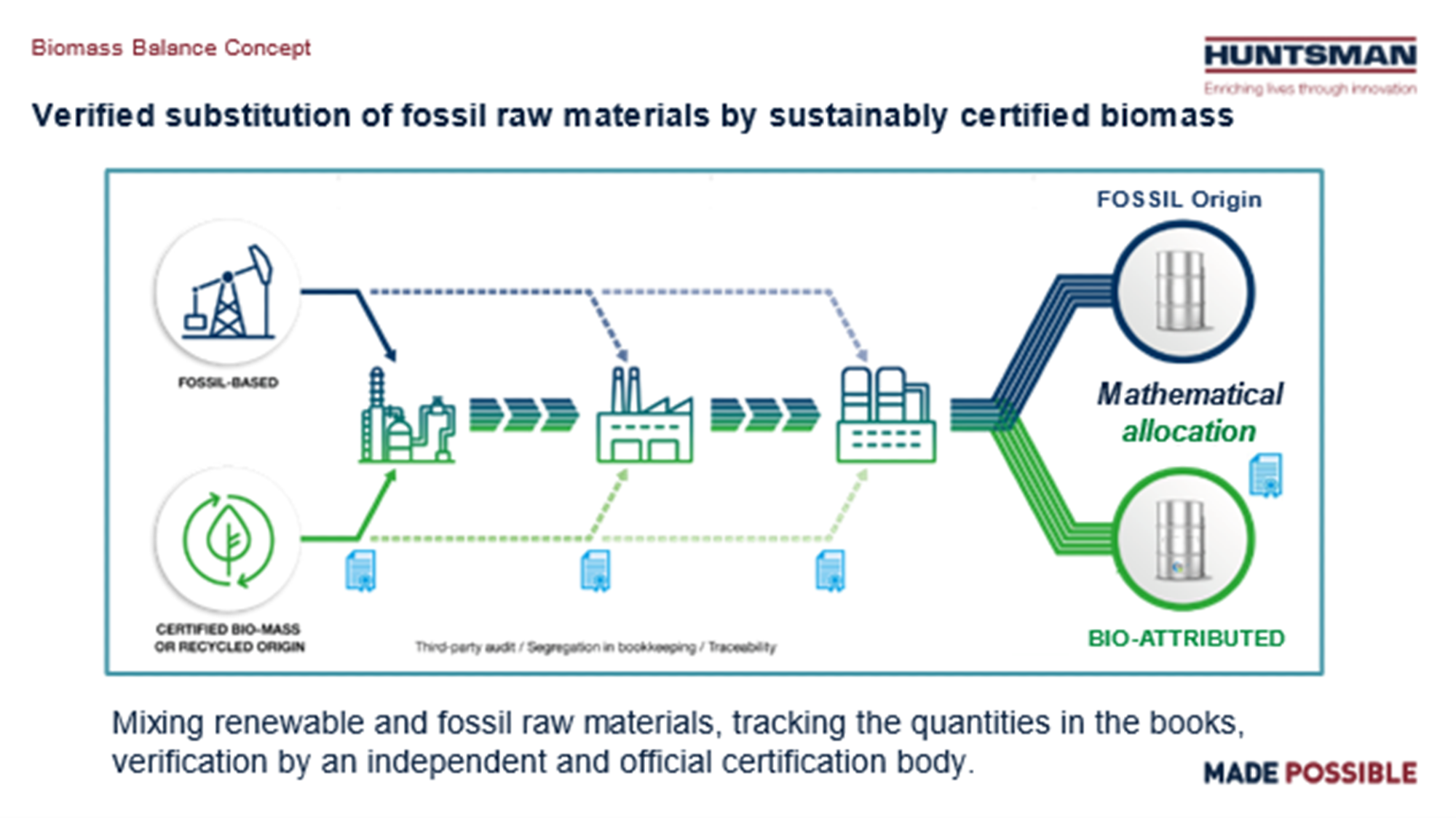

With our composite resins, we've been making them for over 65 years. Our brand is really based on the invention of epoxy in Europe. Over 65 years ago, the predecessor of our company developed epoxy technologies for the aerospace industry, and ever since, we have been driving innovations in the market. Our solutions often address key sustainability challenges and act as catalysts for the success of our customers’ innovation. One example of this is seen in our latest offering, which is bio-attributed, mass balance certified epoxy resins. We have achieved REDcert2certification for a mass balance approach, enabling our customers to decide how much bio-attributed material of feedstock they want to have in the product. And basically, with that, we've enabled the reduction of the CO2 footprint for our epoxy resins by up to 80%, enabling all our customers to take their part in reducing CO2 levels.

Another consideration for the sectors we target is what happens at the end of life. We have launched several initiatives to identify solutions to key challenges. For instance, we are looking at designing new molecules with intrinsic recycling capabilities and we are also looking at the possibilities to recover chemicals from current thermoset polymers. Regarding adhesives, we investigate ways to avoid that - due to their structural performance and durability - they are being considered as an obstacle to the recyclability of parts or products in which they are use.

You have many years of experience developing adhesive technologies. What sets your products apart from competitors?

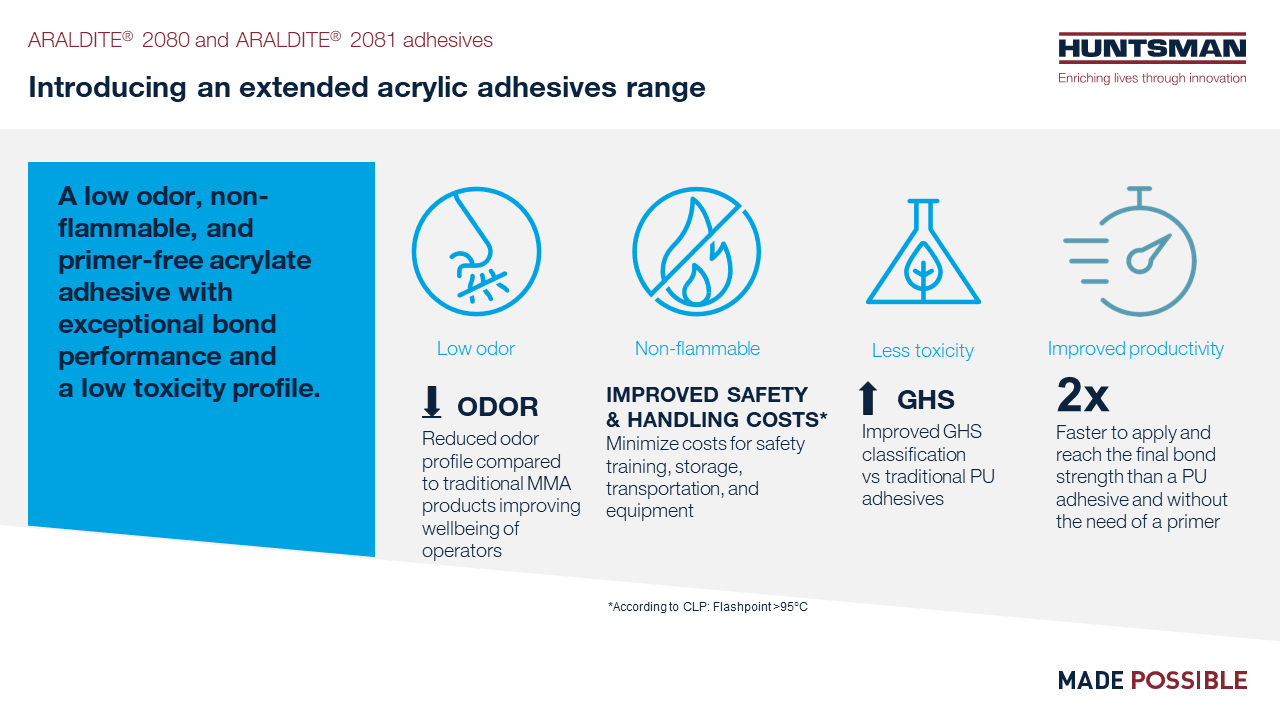

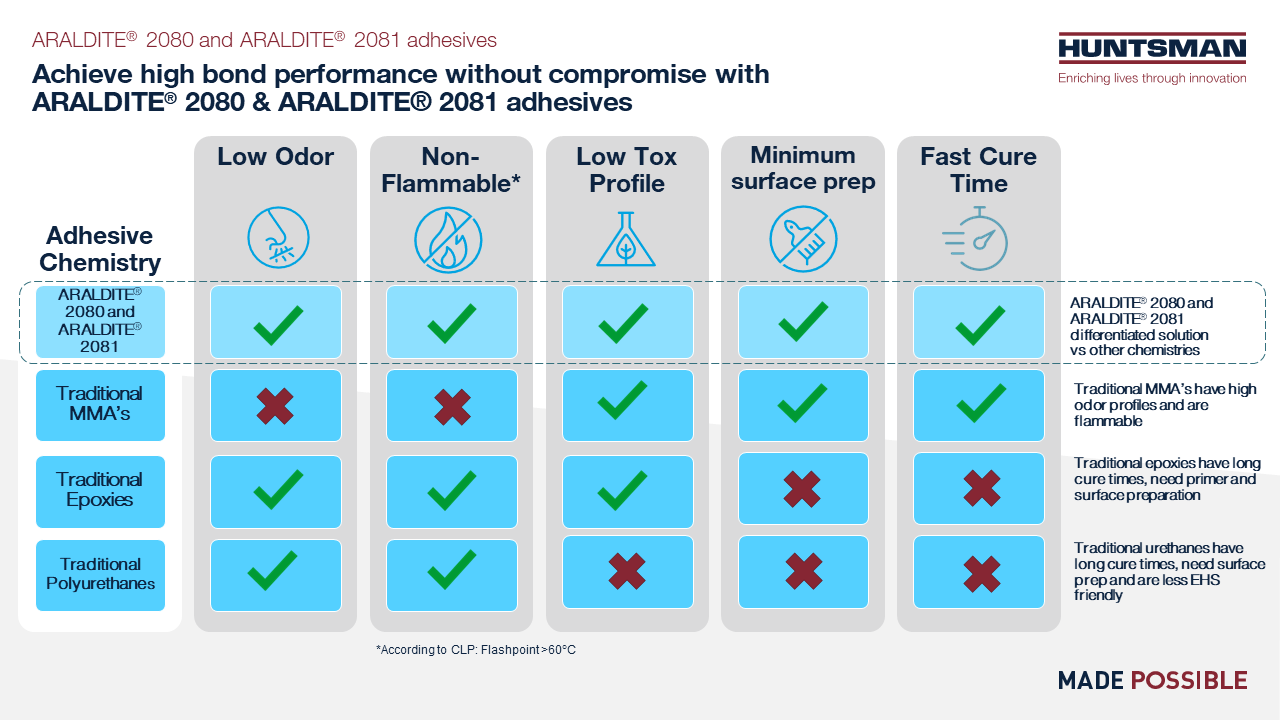

So apart from composites, for our adhesives, I think what sets them apart is that, especially for ARALDITE® 2080 and 2081, for which we won a JEC Innovation Award this year, we have developed a unique structural adhesive that is tough and has a very high technical performance.

At the same time, it also has a very balanced chemistry, enabling a high level of worker safety and worker wellbeing, but also a low tox classification and, importantly, a non-flammable classification. In the end, it is also very good for sustainability because you don't need a means of special transport or special storage, which shortens transportation routes and protocols, resulting in more energy efficiency.

You also don't need extra energy or heat to cure; it cures at room temperature, and that makes it quite a unique product.

Whenever you have a worker that needs to work in a very confined space, you want to give them the best possible chemistry that's technically suitable for the job, making it safe and also comfortable for them to use without requiring bulky or excessive protective equipment.

What does research and development look like at Huntsman?

We have, per division or even per product group, a dedicated R&D team, which is twofold. On the one hand, we have scientists working on the formulation of the adhesives, and on the other hand, we have an application technology group, which works with our customers to understand the way they process and apply the substrates.

I'm part of the technology and innovation group, so basically, I'm marketing inside R&D. We call this strategic marketing and it enables us to work together really well. If an idea comes from the R&D team, I look into it and say, "Okay. Cool innovation, but where's the market and how big is it, or is it something for us?" It can also be the opposite. When I talk with our customers, and we work a lot also with distribution partners, they may say, "I'm just coming back from this customer, and he has a new type of plastic, could be polyamide or other hard-to-bond substrate, for a very specific application." And I might say, "Okay. We don't really have the right adhesive now, so let's take a closer look into it. How big is the potential? And let's develop a new product, because there is a gap in the market."

Why is it important for Huntsman to attend shows like JEC World?

It really depends a lot on personal contact and personal discussions to come up with good ideas. So especially in our industry, whether composites or adhesives, every product and project is unique, and every bonding application is a challenge. Often, it's very important that experts talk to experts to come up with the best ideas.

Most of our team are experts in what they do, from technology to marketing to R&D. They meet our customers, they meet new people, and they talk about challenges they have and how we can overcome them together. It’s so much easier to do that in person than in a virtual environment.

Do you have any exciting developments on the way?

We are really focusing a lot on sustainability, as I said, replacing old inefficient materials with new modern ones that enable our customers to achieve their goals. One area we’re developing is how we can reduce plastic packaging waste. So at the moment, a lot of the adhesives are in solid plastic packaging because of technical reasons, such as stability, shelf life, and so on. But we are showcasing here a concept that reduces plastic packaging waste after use by up to 75% using a different kind of cartridge.

Then, of course, we talked about recycling, and to make recycling possible, you have to also enable adhesives to de-bond at some point. If you look at it technically, it doesn't make sense because our customers tell us that they want to have a bond that's tough and lasts forever. But what happens when the product needs repair or has reached end-of-life? You must come up with ways to enable de-bonding whenever you need to do it. So we also look into that for enabling, repairing, and recycling.

This debonding topic, I think, is really going to be a challenge. Because when we talk with our engineers, they say, "Hey, first you want us to achieve the maximum bond strengths, and they should be chemically resistant; it should work under these conditions and those conditions. And then very efficiently, within five minutes, you want to take it apart again." So how does that work?

Also, looking at the different applications and the different industries we have, there will be no single solution to every problem. That's going to be the challenge, but it's also going to be an interesting one.

Beyond this, we are also, as I said, using bio attribution as a mass balance concept to step by step replace fossil-based materials to reduce the carbon footprint.

And finally, we are also looking into the recycling of composite materials ourselves for carbon fiber structures. At Huntsman, our motto is “Enriching lives through innovation,” and we have an exciting journey ahead.

More from JEC World: How Can Composites Make Construction More Sustainable?

About Alexander Weis

Alexander Weis achieved an M.B.A. in Marketing from the University of Georgia (UGA), USA. He has +20 years’ experience in adhesives and bonding industry, incl. self-adhesive tapes and labels, and has held positions in sales, key account management, product- and market management – always focusing on new, innovative products.

Alexander has worked with customers from many different industries, such as: chemicals, FMCG, home appliances, transportation, furniture, oil & gas. He is currently the European Strategic Marketing Manager for Adhesives at Huntsman Advanced Materials, focused on working closely with technical, R&D, operative marketing, and sales teams, on supporting the successful commercialization of innovations.

Living in Hamburg Germany since 2004, he has two kids (5 and 8) – which keep him busy! He enjoys the outdoors, the beach, mountains, and nature in general, and still goes back “home” to Bavaria as much as he can.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.