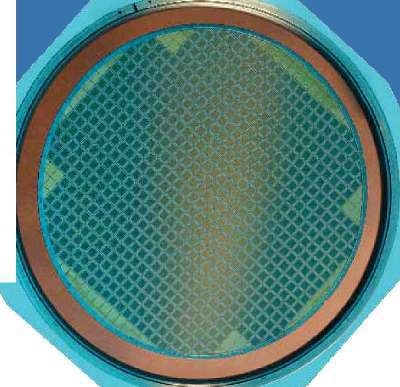

Opportunity for semiconductor suppliers is tremendous as the demand from new energy efficiency industries starts to grow. Nevertheless, the suppliers face mounting challenges during their attempt to increase output of wafers, semiconductor industry raw materials and finished products. Precision controlled heating is a crucial operation in the production of raw materials or crystals for wafers as well as in the final semiconductor product.

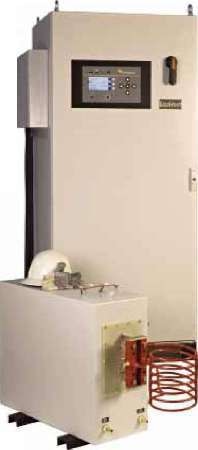

Advanced induction heating from Ambrell adds benefits such as more reliability, precision and cost effectiveness to the crystal growing and wafer production process. Ambrell’s EKOHEAT products are specially engineered for semiconductor applications as they heat the wafer platen or crucible more evenly and efficiently when compared to resistance heating. The company’s non-contact, electromagnetic heating technology saves energy, while improving productivity and delivering a superior quality semiconductor product.

Innovation through Induction Heating – Advantages

Induction technology is a flameless process to heat electrically conductive materials. The fast and clean method electromagnetically creates the required heat to provide a highly controlled environment for crystal growth. Alternating current passes through an induction coil surrounding a crucible. Heat is produced when eddy currents flow within and against the resistivity of the crucible. The heating of the mass is done with unparalleled uniformity, while the coil remains cool.

Process Integration

Ambrell has a good track record of performing advanced research and development to deliver innovative production solutions. The company has more than 20 technology patents and recognized as the key player in solid-state induction heating. Its EKOHEAT solutions help crystal growing system operator to achieve precise control over heating process, enabling stringent regulation of molten mass temperature. Its clean and exacting method to heating in different environments facilitates growth of superior quality crystals.

EKOHEAT by Ambrell.

EKOHEAT design not only allows the meticulous regulation of output power over AC line voltages between 360 and 520 V but also regulates output control between 2% and 100% of full power. This controls the temperature during cooling and heating, thus ensuring more utilization of the Boule. Accurate, frequency-agile tuning not only provides the required precise degree of power for optimal quality under varying load conditions but also precisely changes for process or set-up variations.

EKOHEAT induction heating systems can be easily and rapidly integrated into the existing production process. This not only reduces downtime or modification to the current setup but also provides an innovative and more-efficient heating process. They are automation-ready and feature full analog and digital I/O panels. They can be customized depending on the business requirements of customers. Besides providing a tiny and minimally intrusive footprint, they offer external workheads if the process is remote. The instrumentation in a customer’s operation can be easily accommodated in the built-in 110 or 220 Vac convenience receptacle.

Induction heating delivers sizable energy savings when compared to resistive heating techniques as it focuses exclusively into materials. Moreover, it reduces defect rate and associated costs thanks to its reliability and consistency. Ambrell’s 0.92 power factor further saves energy expenses, shorter heating cycles improve production rates, and induction’s targeted heating purges the cost of furnace ramp-up. Moreover, water cost is decreased due to reduced cooling requirements.

Ambrell assigns an exclusive team of induction heating specialists to a customer to design a customized solution for its discrete or continuous production process. The company will apply its recognized induction heating power systems to a customer’s process. Its service department is prepared to render preventive maintenance and timely emergency support.

Benefits

| The Ambrell Innovation |

The Benefit to Customers |

| Options of external or internal tank circuit |

External tank reduces clean room space, while internal tank |

| Power control using 4-20 mA input |

Facilitates superior crystal growth by controlling power between 2% and 100% of full power |

| Quick on-time for full power |

Eliminates the necessity to scrap the Boule subsequent to short power outages, thus improving crystal quality and reducing waste |

| User-friendly operator interface with digital display |

Reducing operator error through clear readings, thus improving crystal quality |

| Frequency-agile design with more consistent power delivery |

Better crystals, fewer defects |

| Easy change-over of systems for compatibility with various sized crucibles and coils |

Lower heating expenses and enhanced production efficiency |

| Multi-zone heating through separate coils |

Allows for zone refining and accurate control over temperature gradients for better crystal quality |

| Operator preset heating profiles enable replay of fixed processes |

Minimal set-up time and improved productivity |

| Fewer components than other induction heaters |

Improved up time, fewer parts to fail, lower part inventories and eventually lower maintenance expenses |

| Isolated high voltage output to 2500 V |

It is possible to pull larger crystals as higher inductance coils are efficiently powered |

This information has been sourced, reviewed and adapted from materials provided by Ambrell Induction Heating Solutions.

For more information on this source, please visit Ambrell Induction Heating Solutions.