The new CAMSIZER X2 is ideal for substantially improving the quality control of fine powders: More precise and rapid analysis of particle shape and particle size helps to enhance the product quality, save labor costs, energy and raw materials, and reduce rejects.

The design of the CAMSIZER X2 is based on the renowned optical particle measurement system Camsizer but is optimized for finer samples (from 0.8 µm to 8 mm). An extended application range is allowed because of the enhanced optical resolution and also the new options for material feeding. Fine particles are likely to agglomerate which makes it hard to record the properties of a single particle. It is thus important to have different possibilities of feeding the sample to the analysis area in order to find for each material the optimum between the undesired destruction of the individual particle and the desired dispersion of the agglomerates.

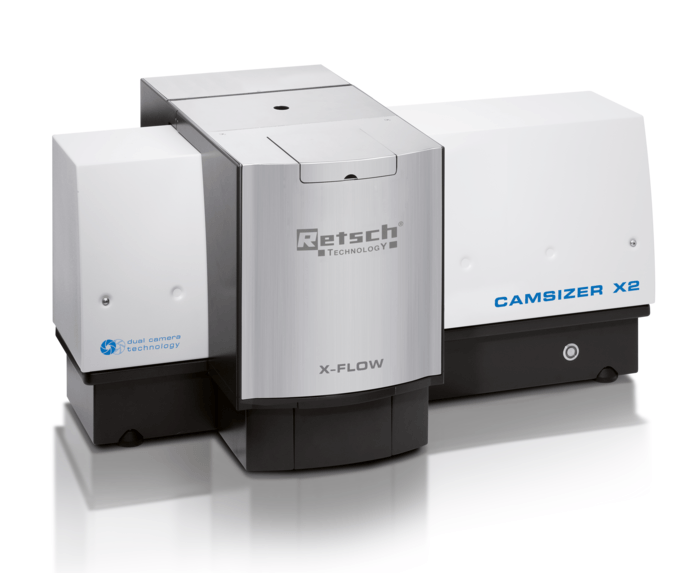

The CAMSIZER X2 provides the flexible X-Change system: from the X-Fall module (free fall mode), which is considered to be the most gentle method for the material, to the X-Jet module with variable nozzle geometry and adjustable pressure and, additionally, the X-Flow module in which particles are dispersed in liquids, optionally by an ultrasonic probe.

Application Examples

abrasives (medium-size and small grit), cement, chemicals, construction materials, activated carbon, detergents and enzymes, foodstuffs (pulverized and granulated), glass beads, metal and ore powders, pharmaceutical powders / granules / fine pellets, plastic powders, plastic fibers, salts, sugar, wood fibers, sand

Product Advantages

- Reliable detection of smallest amounts of "oversize" and "undersize"

- Extremely short measurement time of 1 - 3 minutes

- Modular system X-Change for wet and dry dispersion

- Measurement results are 100% compatible to sieve analysis if needed

- Intuitive software

- Digital image processing with patented two-camera-system (acc. to ISO 13322-2)

- Calibration in seconds

- Simple handling prevents operating errors

- Password protected instrument settings

- Automatic measuring procedure

- Robust design, insensitive to vibrations and dust

- Self-cleaning, maintenance-free, wear-free

- Several language versions (English, German and other languages)

- Detailed particle size analysis - results are saved in more than 1,000 size classes

- Simultaneous analysis of particle size, number, shape, transparency and density

- No-contact, non-destructive measurement

- Less time and labor intensive than sieve analysis

- Wide dynamic measuring range from 0.8 µm to 8 mm (extended measuring ranges available)

- Newly developed optical system with ultra-strong LEDs for highest resolution and exceptional depth of sharpness

Features

| . |

. |

| Measuring principle |

Dynamic Image Analysis (ISO 13322-2) |

| Measuring range |

Standard

0.8 µm to 8 mm

10 µm to 8 mm (gravity dispersion)

0.8 µm to 5 mm (air pressure dispersion)

0.8 µm to 1 mm (wet dispersion)

extended measuring ranges |

| Type of analysis |

dry and wet analysis |

| Measuring time |

~ 1 to 3 min (depends on desired measuring statistics) |

| Number of cameras |

2 |

| Sample volume |

< 20 mg - 500 g (depends on sample type and measurement mode) |

| Measuring methods |

> 300 images/s, each with approx. 4.2 MPixel |

| Width of analysis area |

~ 20 x 20 mm |

| Resolution |

0.8 µm per pixel |

| Measurement parameters |

particle size (smallest diameter, length, mean diameter, etc.) particle shape (aspect ration width to length, symmetry, sphericity, convexity etc., acc. to ISO 9276-6) |

| Dimensions (W x H x D) |

~ 850 x 580 x 570 mm |

| Weight (Measuring unit) |

~ 50 kg |

| Operating unit |

Quad Core PC incl. Windows 10, monitor, keyboard and mouse, network card, PC interface cards for hardware communication, evaluation software |

Function Principle

The CAMSIZER X2 makes use of the principle of digital image processing. The patented principle is reasonably simple: Dispersed particles travel in front of two bright, pulsed LED light sources. Two digital cameras are used for capturing the shadows of the particles.

One camera is optimized to examine the small particles with high resolution, the other camera for identifying the big particles with a good statistic, that means large field of view. Each camera is illuminated by one LED with optimized brightness, field of view and pulse length. A user-friendly software is used for analyzing the shape and size of each particle, and it finally calculates the respective distribution curves in real-time.

Particle X-Plorer Software Module - RETSCH TECHNOLOGY

Particle Analyzer CAMSIZER X2 - RETSCH TECHNOLOGY