The quick production of freeform, large departure components, using an Ultra Precision Diamond Turning Lathe, is possible using the Precitech Slow Tool Servo (STS).

The STS uses a Diamond Tuning Lathe for fast, high-volume manufacturing of large departure freeform components. The tool holder of the STS is actuated (by the motion of its slide) in time with the spindle’s rotation and cross slide, which facilitates the formation of larger departures at lower speeds.

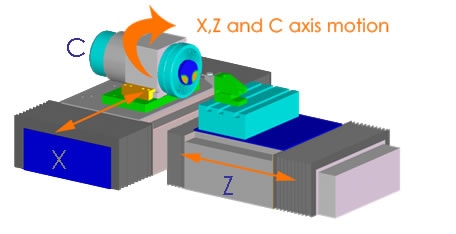

Using a system different from the Fast Tool Servo (FTS), the STS’s tool position is described and controlled by three axes of motion on the machine’s controls. In addition to the above, the STS also includes control software and a specially tuned Z-slide.

The STS’s design, with a positioning C-axis, provides the ability to diamond turn complex surfaces such as off-axes aspheres, torics and progressive lens designs. This facilitates the machining of large-scale sagittal workpieces, without the requirement of extra equipment.

Specifications

- 10 mm amplitudes at 2 HZ*

* Larger excursions available at lower frequencies.