Maximize performance and minimize errors with METTLER TOLEDO’s intuitive refractometers.

Performance Meets Simplicity

The Excellence Refractometers from METTLER TOLEDO have been designed to measure virtually any sample with excellent precision and can be used in a wide range of industries.

With features like intuitive operation, measurements of up to five decimal places, and a modular workflow, users can easily eliminate inaccuracy and produce precise, repeatable results.

The Excellence benchtop refractometers offer an ideal solution today and a valuable foundation for the future.

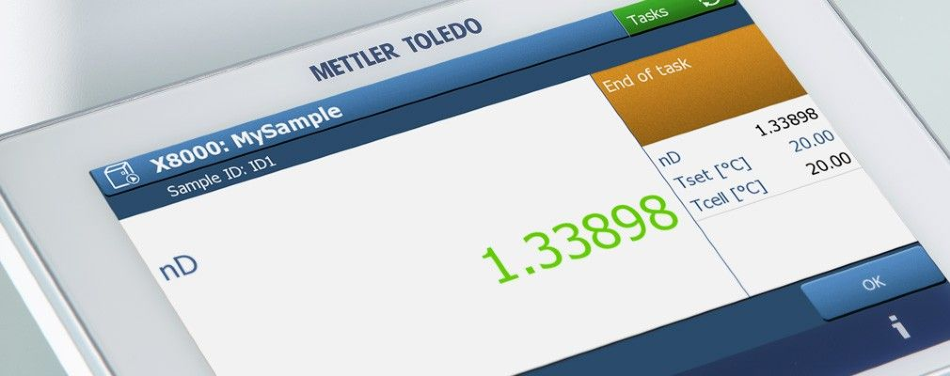

Keep it Simple

The Excellence benchtop refractometers have made refractometry quite easy. With an intuitive touchscreen user interface and easy operating routines, users can carry out measurements rapidly and efficiently.

Shared across various METTLER TOLEDO analytical solutions, the One Click™ user interface offers easy access to all the operations required by users, streamlining their daily work and making them feel right at home.

Image Credit: METTLER TOLEDO

Streamline Quality Control

Training and operator impact can be minimized with just a single click to make completely automatic quality control analysis. Users have to simply click on the product shortcut: quantified products are automatically validated, and the color of the result shows whether specifications have been fulfilled.

Image Credit: METTLER TOLEDO

Automate Analysis

Users can save time, minimize costs, and enhance operational safety by reducing the need for operator interaction. The quality of measurement data can be increased by automating the analysis. This ensures that all steps are carried out in the same way, all the time.

With fully automatic determination, users can take the reliability and repeatability of results to a completely new level.

Image Credit: METTLER TOLEDO

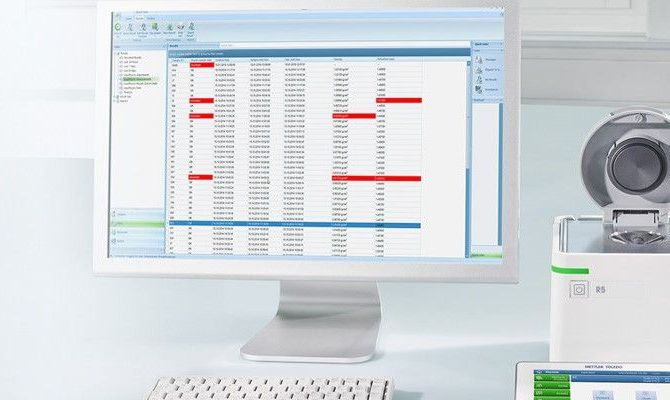

Go Digital with LabX®

Users can future-proof their laboratories. The LabX® PC software is more than just an instrument management software. It manages instruments, data, and users while bringing all the operations directly to the touchscreen of the instrument.

With bi-directional integration into the LIMS, ELN, or SAP systems, users can ensure data integrity, save paper, and prevent transcription faults.

Image Credit: METTLER TOLEDO

Save Time with Multiparameter Measurements

Multiparameter analyses help to make the most of one’s time while improving data quality. They help integrate refractive index, pH, density, titration, and more and prevent the modification of samples between each analysis.

Results can be shown directly on the instrument screen, guaranteeing that all the data is easily accessible.

Image Credit: METTLER TOLEDO

Improve Workflow

Users can log in with their biometric fingerprint, enter a product ID using a barcode scanner, commence the measurement by waving a hand, and export results to a USB printer, PC software, USB stick, ERP, LIMS, or SAP.

High performance of the instrument can be consistently ensured with standard calibration using certified traceable standards.

Image Credit: METTLER TOLEDO

Refractometer—Benchtop Digital Refractometer

METTLER TOLEDO’s benchtop refractometers come with an integrated Peltier thermostat to precisely regulate the temperature. Therefore, a water bath is no longer needed.

The benchtop refractometers can be linked to a UV-VIS spectrophotometer, density meter, titrator, pH meter, or other kinds of instruments to quantify a number of parameters at the same time. Different automation units are also provided to additionally enhance productivity.

The Excellence Line from METTLER TOLEDO is the outcome of elaborate research and technology innovation, invariably focusing on attending the costumer’s requirements.

Applications

The following measuring scales are preserved in the instrument for particular applications:

- Sugar: Brix, HFCS55, HFCS42, Oechsle, and Invert Sugar

- nD, Zeiss (15.00), Zeiss (14.45), chemicals, salt, acid/base scales, and freezing point scales

Some of the standard applications of refractive index measurement are applications in fragrances and flavors production, applications in fats and oils production, Brix measurement, and analysis of juices, carbonated beverages, and juice concentrates.