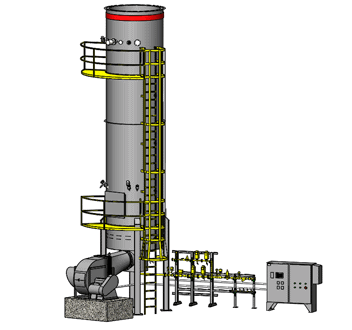

The Anguil Vapor Combustion Unit incorporates the efficiency of a thermal oxidizer with the simplicity of an enclosed flare. Anguil VCU technology has several advantages over conventional enclosed combustion systems, whether installed on a continuous emission stream or intended for intermittent use.

It is a durable device that can handle changing emission flow rates and concentrations.

Image Credit: Anguil Environmental Systems

There are two fundamental types of flame burners: open and enclosed. These burners are employed in thermal flaring technologies to destroy hydrocarbons, volatile organic compounds (VOCs), or hazardous air pollutants (HAPs).

Recent limitations on greenhouse gases (GHGs), vapor radiation, visible emissions, and noise pollution have compelled the industry to switch from open flaring to enclosed vapor combustion systems.

Product Overview

Benefits of Anguil’s VCUs

- The requirement for water or steam injection is eliminated via a proprietary burner design

- The design of the air staging burner further minimizes the output of nitrogen oxides (NOX) and carbon monoxide (CO)

- Skid-mounted style makes installation easier and costs less

- Multiple independent process streams can be injected separately and simultaneously owing to a specialized burner design

Image Credit: Anguil Environmental Systems

- 99%+ Destruction Rate Efficiency (DRE), Regulatory Compliance Guaranteed

- Optional Corrosion Resistant Coatings

- Access Ladder & Platforms to Sample Ports & Combustion Chamber

- Free Standing Fuel Train & Control Rack

- Forced Draft or Natural Draft Systems

- Free Standing Construction

- Gas trains are designed to meet FM Global or any international certifications such as CSA, EN, TSSA, or CGA

- Programmable Logic Controllers (PLCs): automate operation startup to shut down, minimizing operator interface requirements. Remote telemetry capable with various enclosure options

Air Flow Range and Efficiency

Air Flow Range

- Varying flows and concentrations

Turndown Capabilities

Destruction and Removal Efficiency

Ideal Applications

- Changing vapor concentrations and process flow rates

- High emission destruction requirements

- Low maintenance demands

- Mixing operations, tank vents, loading stations, and more

Features

Features and Design Options

- Flame-arresting burners for flashback mitigation and safe operation

- Reliable, automatic pilot ignition systems

- Sample test and sight ports

- Gas trains are designed to meet FM Global or any international certifications such as CSA, EN, TSSA, CGA, and ATEX

- Robust Programmable Logic Controller (PLC) based controls with digital data recording, remote telemetry, and various configuration options

- Process gas capacities up to 100 MMBTU/H

- Destruction rate efficiencies up to 99+%

- Multiple burner options for fuel input, including natural gas, propane, and hydrogen, as well as ultra-low NOx or electric heating elements

- High turndown capabilities / 10:1 or greater

- Fully integrated burner management system

- Stainless steel construction on components susceptible to weather damage

Options

- Corrosion-resistant metallurgies

- Detonation or deflagration flame arrestors

- Natural draft or forced draft combustion

- Knockout pots for upstream liquid separation

- Forced draft configuration

- Low, medium, or high-temperature designs

- Refractory lined with ceramic fiber insulation

- Heat transfer tubes for process heating needs

Image Credit: Anguil Environmental Systems

Operating Cost Reduction Strategies

- Oxidizer Service and Preventive Maintenance Evaluations (PME)

How Do Vapor Combustors Work?

Depending on the sector, the terms Low Emission Flare (LEF), Medium Temperature Flare (MTF), High-Temperature Flare (HTF), Industrial Burners, Enclosed Flares, Biogas Flares, Gas Burners, Fired Heaters, Open Flame Flare, Candlestick Flare, Flare Stack, Thermal Combustors, Fire Box, Enclosed Burners, and Vapor Combustor Units (VCUs) could be interchanged.

A purge sequence within the VCU is initiated before the introduction of process gases to eliminate any existing combustibles from the device. Only once the system controls establish a safe state can the pilot ignite. The process gas enters the system via an isolation valve or intake duct. These process emissions are subsequently used to feed the combustion device.

Under low process pressure settings, Anguil’s vapor combustion unit can be configured in a natural draft configuration, eliminating the requirement for combustion air fans, or with a blower package.

The combustion air is typically pulled into the destruction chamber via one or more natural-draft air inlets. Temperature control is provided automatically by modulating control dampers, which provide optimal combustion temperatures for the oxidation of the various components.

In the case of highly variable process circumstances, both in terms of flow and hydrocarbon content, emissions can be fed into the combustion chamber via a variety of different burner heads or stages.

The gradual introduction of process gases results in larger system turndown ratios and lower GHG emissions such as NOX and CO2. This steady, staged combustion burner can also destroy emissions at low working temperatures, typically between 1500 and 1800 °F (815 and 982 °C).

In the combustion chamber, process gases are typically destroyed during operation using an exothermic reaction. When there are insufficient VOCs to support oxidation on its own, additional fuel is needed to achieve destruction temperatures.

In low BTU content process gas conditions, the natural gas burner is solely employed as supplemental firing to maintain operating temperature and emission destruction. The VCU often achieves destruction efficiency of up to 99+% with the right combination of duration, temperature, and turbulence.