The Emission Concentrator from Anguil is an adsorption system developed to concentrate low-concentration, large-volume process exhaust into a much smaller, more concentrated air stream.

The highly reduced flow with higher Volatile Organic Compound (VOC) concentration is transmitted to a thermal or catalytic oxidizer available for VOC destruction.

Furthermore, the destruction device can be much smaller, considerably decreasing capital cost. The consecutive higher VOC concentration regulated in the smaller abatement equipment reduces auxiliary fuel consumption.

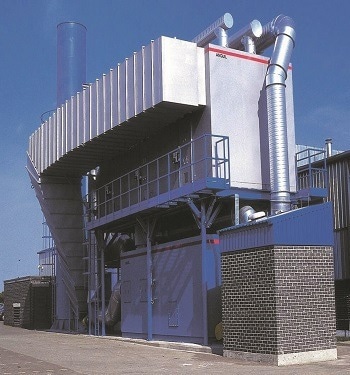

Image Credit: Anguil Environmental Systems

Product Overview

Benefits of Anguil’s Emission Concentrators

- Largest flow capacity in the industry at more than 120,000 SCFM (192,600 Nm3/hr) in a single rotor

- Helps decrease abatement equipment size by around 90 to 95% of the original volume, offering striking capital and operating cost energy savings

Air Flow Range and Efficiency

Air Flow Range

- 5,000 to 120,000 SCFM (8,025 to 192,600 Nm3/hr) (Single Rotor)

Destruction and Removal Efficiency (DRE)

- 95 to 99% (Higher DRE could be achieved with several rotors in series)

Ideal Applications

- Low relative humidity and 90% max RH

- Large volume and low concentration

- Exhaust of 100 °F (38 °C) or less has been provided

- Around 99%+ Destruction Efficiency (DRE), Regulatory Compliance Guaranteed

- Programmable Logic Controllers (PLCs): operation startup to shut down could be automated, reducing operator interface needs. Remote telemetry allows the system’s operation to be viewed and altered through a modem, decreasing maintenance charges and downtime. Comes with control rooms and several enclosure options.

- Zeolite wheel options to avoid polymerization and reduce the risk of fires.

- Concentration ratios as high as 20:1

- High-efficiency filter plenums available

- Concentrator wheel, desorption air heat, and oxidizer combined as a single system, simplifying the installation and control scheme

- Numerous options for the source of desorption air heat.

- Regenerative Thermal Oxidizers (RTO’s), Thermal Recuperative Oxidizers, and Catalytic Recuperative Oxidizers can be supplied to treat the concentrated stream.

Image Credit: Anguil Environmental Systems

Features

- Entirely shop-assembled, pre-wired, and tested before shipment

- Removal efficiencies range from 95 to 99%

- Zeolite adsorbent rotor reduces the risk of fires common to carbon systems with some VOC or HAP emissions.

- Low-pressure drop, normally 3″-5″ W.C.

- The concentration ratios provided are as high as 25:1

- Constant adsorption of VOCs onto the rotor is contrary to batch-type adsorption vessels.

- Comes with desorption air heat, concentrator rotor, and oxidizer combined as a single system, thereby streamlining installation and controls

- More than 120,000 SCFM (192,600 Nm3/hr) capacity with a single rotor system

- Robust Programmable Logic Controller (PLC) based controls with digital data recording, remote telemetry, and various configuration options.

Options

- Several rotors are available in series or parallel for even higher DRE or higher airflows

- Numerous zeolite substrate options to prevent polymerization

- Several options for the desorption of air heat

- Completely-integrated concentrator–oxidizer systems, including standard controls stream

- High-efficiency filter plenums to safeguard the adsorbent from process particulate exhaust

Image Credit: Anguil Environmental Systems

Operating Cost Reduction Strategies

- Primary or secondary heat and Energy Recovery Solutions

- Oxidizer Service and Preventive Maintenance Evaluations (PME)

How Do Emission Concentrators Work?

The high volume and low concentration airstream pass via a rotor concentrator where VOC emissions have been stripped from the air and adsorbed onto the zeolite.

The majority (around 90 to 95% of the total air volume) of this clean air is then exhausted into the atmosphere. A small portion of the air stream (approximately 5 to 10% of the total air volume) is heated to a high temperature for desorption air.

The concentrator rotor spins constantly at a very slow rate, transporting adsorbed pollutants into a desorption section. Regarding the desorption section, the VOCs are released or desorbed from the adsorptive media with the low-volume heated airstream—an oxidizer further processes this low-volume, high-VOC-laden air.

The concentrator with the combined oxidizer is usually the most affordable technology for processing high-volume and low-concentration streams. While the capital cost of a system has been competitive with other technologies, the true savings is identified in decreased operating costs.

An oxidizer will function with little to no natural gas consumption when coupled with a concentrator. At higher concentration values, it has enough “free energy” to offer desorption energy for the concentrator.