The innovative DSC 300 Caliris® Classic is user-friendly, accurate, robust, and optimized for daily use. This instrument's special design comprises everything required for successful DSC investigations—irrespective of whether the user is a beginner or an experienced professional.

The innovative software sets new standards: the established AutoEvaluation and Identify currently fulfill the next generation of data management LabV®, which maintains track of the gathered data and sets it up for a smooth laboratory workflow.

The DSC 300 Caliris® Classic provides:

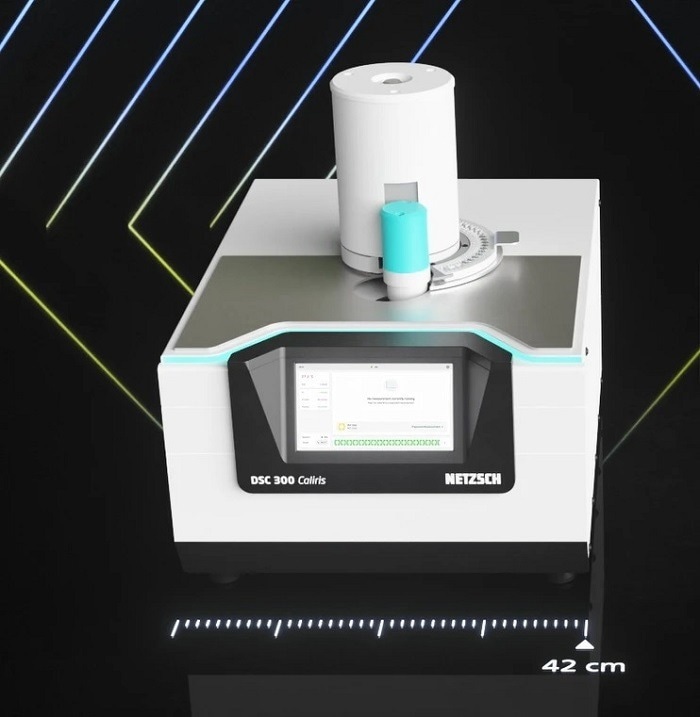

- A small design for more space in users’ laboratory

- Smart software that enables users to begin quickly with DSC measurements

- Automated measurement and evaluation, making routine simple

DSC 300 Caliris Classic

Video Credit: NETZSCH-Gerätebau GmbH

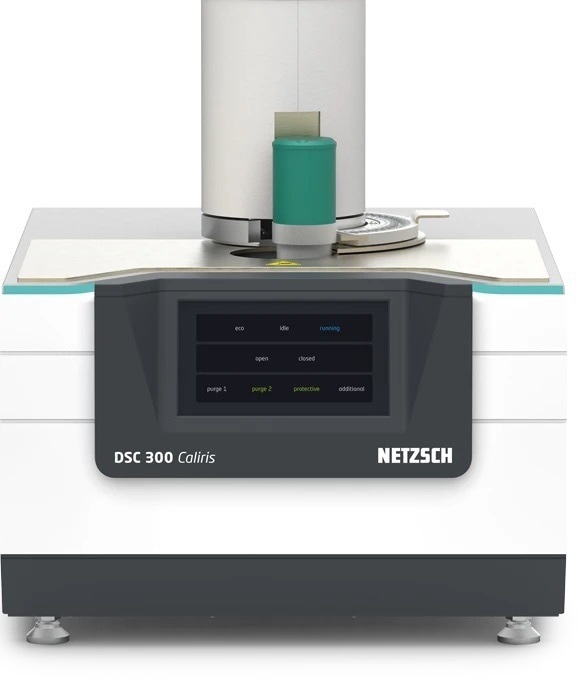

Compact Lab Instrument

Laboratory space usually comes at a premium cost. Therefore, the DSC 300 Caliris® Classic's small design with cooling accessories like the intracooler makes it a fantastic choice. It is ideal for at-line testing and could easily be set up in a production environment for QA or QC purposes.

Image Credit: NETZSCH-Gerätebau GmbH

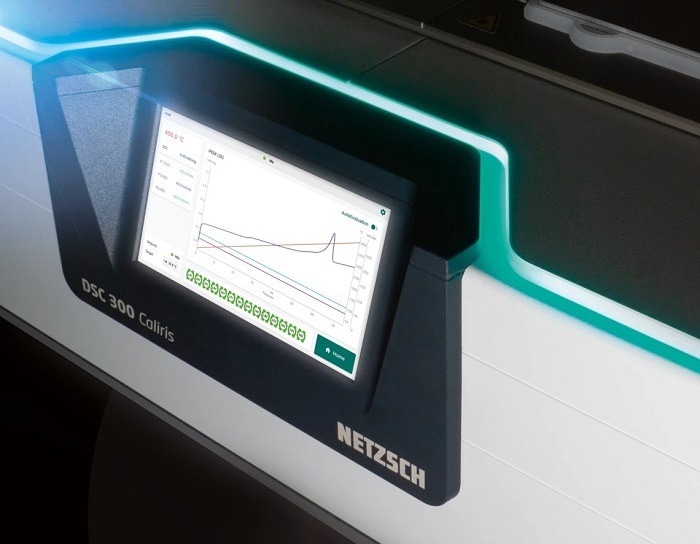

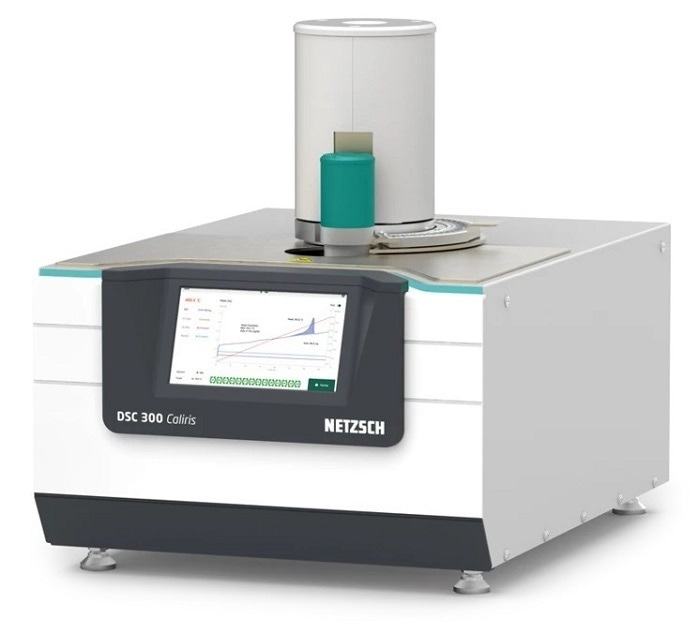

Touch Display for Improved Productivity and Workflows

Besides the conventional display, the DSC 300 Caliris® Classic provides an optional integrated touchscreen display with elaborate instrument and measurement information.

As soon as a measurement has been made with the help of the Proteus® software, it can be started instantly from the touch display. When a measurement is prepared, the touch display offers up-to-the-minute measurement information without PC access.

Image Credit: NETZSCH-Gerätebau GmbH

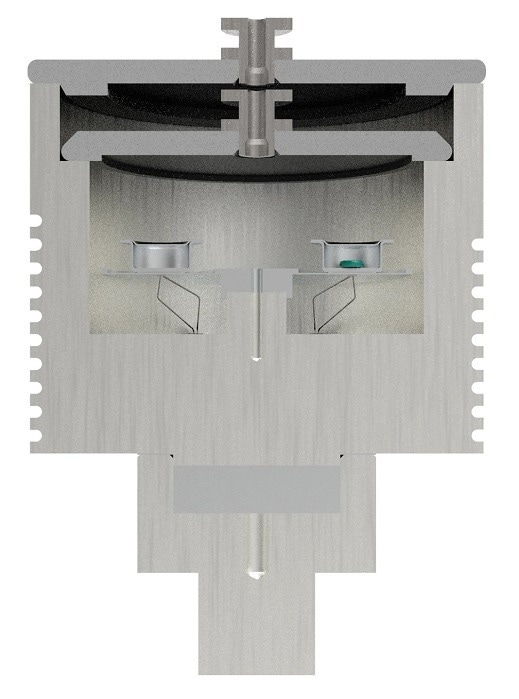

Excellent Performance Even in Less-Than-Perfect Environments

The monolithic DSC sensor is stable in tough environments and offers ideal resolution. The thermocouple wires and sensor disks are laser-welded for ruggedness and high sensitivity.

The sensor can also be cleaned with a glass fiber brush. In case of undesirable cell contamination or sensor contamination, the temperature range of up to 600 °C enables simple cleaning by baking out the contaminants. Cleverly designed connectors enable rapid and straightforward installation of numerous cooling systems

Ideal Combination of Furnace, Sensor, and Crucible. Image Credit: NETZSCH-Gerätebau GmbH

The Future is Now

Users can bring the devices into their laboratory with a click of a button.

Users can scan the QR code and get a 3D model of the instrument directly on users’ mobile phones or tablets. Using the latest artificial reality (AR) technology, the 3D model can easily be positioned in users’ laboratories in its original life-size. This function is browser-based and requires no app.

Image Credit: NETZSCH-Gerätebau GmbH

Technical Data

Temperature Range

−170 °C to 600 °C

Automatic Sample Changer

For up to 20 samples and references

Heating/Cooling Rate

0.001 K/minute to 100 K/minute

Enthalpy Precision

± 0.1% for indium

Specific Heat Determination

Optional

Temperature modulation

Optional

Gas Atmospheres

Inert, static, oxidizing, and dynamic operation

Automatic Sample Changer (ASC)

Up to 20 samples and references, optional available

Cooling Device Options

- Compressed air cooling (RT to 600 °C)

- IC40 (−40 °C to 600 °C)

- IC70 (−70 °C to 600 °C)

- LN2 (−170 °C to 600 °C)

Indium Response Ratio

>100 mW/K

(Mean value, connected indium as standard material under measurement conditions normally utilized for polymer investigation)

Heating/Cooling Rate

(Maximum rate relies on temperature)

Image Credit: NETZSCH-Gerätebau GmbH

Image Credit: NETZSCH-Gerätebau GmbH

Software Proteus®

Get started quickly with SmartMode

The system’s SmartMode interface has been thoroughly developed with a clear and steady structure, guaranteeing simple navigation and easy use, even for beginners. Its intuitive interface offers rapid and effective access to the information users need.

The Wizards menu provides an extensive set of pre-configured measurement templates that need the least input, enabling instant measurements with a single click.

In the Predefined Methods section, users will determine all of the materials that have been featured in the NETZSCH Thermal Properties of Polymers, which could also be discovered on the NETZSCH Polymer Poster, together with corresponding measurement techniques that have been particularly developed for experimentation.

The User Methods menu enables users to save their earlier executed techniques as templates for future measurements. This removes the need to redefine measurement parameters often, simplifying the process.

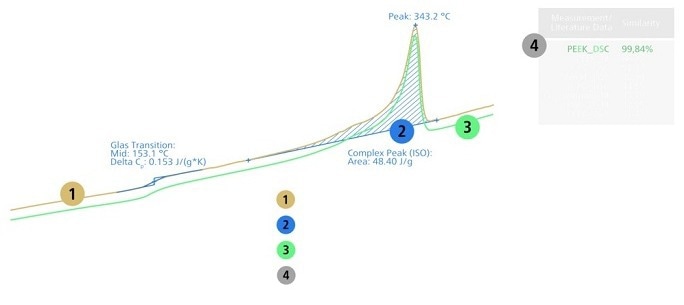

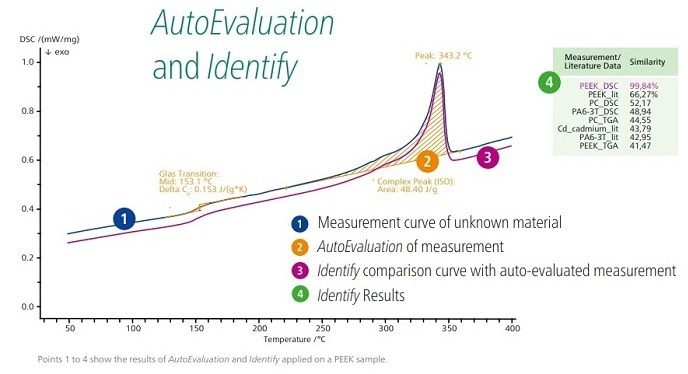

AutoEvaluation

AutoEvaluation is an intelligent software enabling the evaluation—self-acting or at the push of a button—of unidentified curves.

AutoEvaluation examines DSC curves by first identifying any critical effects like glass transitions or melting peaks, and further correctly rendering side effects like recrystallization effects in logical steps.

Initially, users can access expert applications knowledge through an intelligent software algorithm.

Image Credit: NETZSCH-Gerätebau GmbH

Identify

Identify is a unique software tool for classifying and identifying measurements through database comparison. As well as enabling one-on-one comparisons with separate curves and literature data, it also checks if a specific curve belongs to a few classes.

These classes comprise curves of the same material type (material identification) or reference curves for Pass or Fail testing (quality control).

The NETZSCH libraries offer around 1300 entries concerning various application areas such as organics, polymers, inorganics, pharmaceuticals, metals/alloys, and ceramics.

The KIMW* database comprises the DSC curves for another 1,150 commercially available polymer products. Users can expand Identify as desired, adding endless amounts of their data. Generally, all database entries act as a pool of outcomes and beneficial measurement conditions.

Image Credit: NETZSCH-Gerätebau GmbH

LABV®

LabV®®-Primed-Enter the Digital Lab

The volume of data recorded in analytical laboratories is increasing continuously. People, devices, and systems will be connected end-to-end in future laboratories.

Tracking and organizing gathered data from analytical instruments for additional experiments, final reports, or comparisons is critical to simplifying laboratory workflows. Predictions based on collected data enhance quality, part and process performance, making the future laboratory highly efficient.

The NETZSCH DSC 300 Caliris®® comes LabV®®-primed. Utilizing the optional LabV®® cloud solution keeps all users’ laboratory data in one place and connects all users’ devices and systems regardless of manufacturer.

Effortless documentation provides more time for tests and interpretation of data. LabV®® links all the analysis methods, making processes transparent. Projects turn out to be highly flexible, and product quality is predictable.

PROTEUS® Search Engine

Proteus® Search Engine’s extensive search capability increases users’ analysis tasks and data exploration effectiveness and efficiency. It offers various convenient features to improve data handling.

Users can easily access and sort data depending on specific criteria and can effectively arrange and navigate via users’ stored information. The system also offers a preview feature that lets users view their stored data without opening individual files.

This preview capability stretches to measurements and analyses, enabling users to assess their contents without laborious file openings rapidly. The system offers strong search capabilities that allow users to quickly determine data utilizing several parameters like instrument name, operator, file, method, signal type, date, measurement conditions, or evaluated effects.

Autocalibration

Calibration of the DSC instrument is a prerequisite for proper DSC measurements. It guarantees that the instrument always quantifies within pre-defined parameters. However, the calibration process must be easy, quick, and ideally performed together with the process.

The solution for this is AutoCalibration. This unique software-developed feature provides pre-defined calibration techniques for common standards and begins the calibration measurements. It also automatically examines melting peaks, computes calibration curves, and checks their validity.

AutoCalibration makes a regular task that could otherwise be very laborious simpler.