ESI Group has unveiled two new composites manufacturing simulation solutions, PAM-FORM and PAM-RTM. These solutions are ideal to design and enhance manufacturing processes of prepregs and dry textiles. They help to achieve improved quality and also minimize composite part production time cycle and cost.

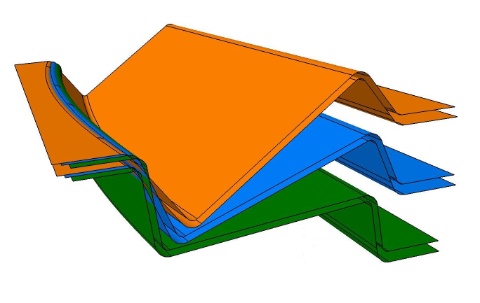

Thermoplastic rib forming simulation using PAM-FORM

Thermoplastic rib forming simulation using PAM-FORM

The PAM-FORM simulation application was developed through several collaborations in defense, aerospace, automotive and other fields. The solution is suitable for several composites manufacturing processes, including rubber pad forming, stamping, hand lay-up diaphragm forming and stamping. It allows simulation of forming and pre-forming processes of laminated composite parts in a realistic manner. This helps engineers to choose the right material, tooling design and top process parameters. With the use of PAM-FORM tool, engineers can also forecast manufacturing defects such as bridging, excessive shearing, wrinkling and improper thickness distribution, and rectify them by changing the tooling or process parameters.

ESI Group has designed the PAM-RTM solution for resin infusion or injection of composite performs. The tool helps to predict manufacturing process of large-sized and thicker composite parts that are commonly found in automotive, aeronautics and wind sectors. It addresses different Liquid Composites Molding production processes, including Compression-RTM (CRTM), Articulated-CRTM (A-CRTM), Vacuum Assisted Resin Infusion (VARI), Vacuum Assisted RTM (VARTM) and Transfer Molding (RTM).

Source: http://www.esi-group.com/