Sep 29 2014

An international team of researchers from Rice University, Marseille University and the Massachusetts Institute of Technology have developed atom-scale computational models to enhance the properties of concrete for general applications.

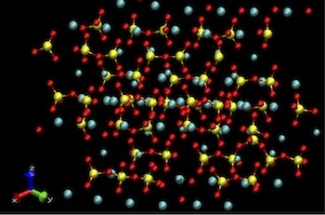

The generic molecular structure of cement consists of silicon (yellow) calcium (blue) and oxygen (red) atoms, with the addition of water molecules (not shown). A team of scientists including Rouzbeh Shahsavari of Rice University has created computational models to help concrete manufactures fine-tune mixes for specific applications. Courtesy of the Shahsavari Lab

The generic molecular structure of cement consists of silicon (yellow) calcium (blue) and oxygen (red) atoms, with the addition of water molecules (not shown). A team of scientists including Rouzbeh Shahsavari of Rice University has created computational models to help concrete manufactures fine-tune mixes for specific applications. Courtesy of the Shahsavari Lab

The new computational models will help manufacturers of concrete to tune their mixtures so as to suit specific applications.

Worldwide, over 20 billion tons of concrete are produced every year. This contributes to around 5 to 10% of the carbon dioxide emissions release to the atmosphere, which makes it the third-largest source of greenhouse gas.

Rouzbeh Shahsavari, a materials scientist and assistant professor of civil and environmental engineering at the Rice University, stated that the computational models would help optimize the production process for concrete, which will be beneficial for construction and also for the environment.

Concrete is composed of calcium, silicate and water (C-S-H). The researchers attempted to enhance the mechanical properties of concrete by decoding C-S-H phases in various chemistries. The attributes contributing to defects in concrete were analyzed. The topology of structures at their atomic-level and the calcium to silicon ratio were studied. The bonds between atoms of silicon and oxygen, and calcium and oxygen were analyzed along with the defect locations. Concrete derives its properties from these defects.

The researchers studied how regimentation or randomness affected properties of concrete. The calcium to silicon ratio is important and a lower content of calcium would provide equivalent strength and would also be friendlier to the environment. A higher calcium content would, however provide increased fracture toughness, that would be favorable for bridges and buildings.

The researchers observed that based on molecular topology new degrees of freedom were seen in concrete formation. Around 10-20 molecular shapes with specific mechanical properties were observed for particular ratios of calcium and silicon.

MIT’s Concrete Sustainability Hub, the National Ready Mixed Concrete Association Research and Education Foundation and the Portland Cement Association have supported this study which has been published online in Nature Communications.

References