Mar 20 2015

Scientists from the Empa-led EU project 'TREASORES', have demonstrated novel silver-based transparent electrodes and prototype flexible solar cell modules that are capable of performing better than materials that are currently being used.

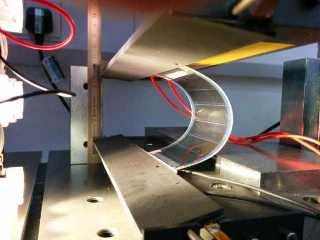

A flexible organic solar cell from TREASORES project undergoing mechanical testing: the cell is repeatedly flexed to a 25 mm radius whilst monitoring its performance. Such cells have shown lifetimes in excess of 4000 hours. (Image: National Physical Laboratory (NPL), England)

A flexible organic solar cell from TREASORES project undergoing mechanical testing: the cell is repeatedly flexed to a 25 mm radius whilst monitoring its performance. Such cells have shown lifetimes in excess of 4000 hours. (Image: National Physical Laboratory (NPL), England)

Flexible optoelectronic devices hold promise for developing cheaper solar cells, LED lighting panels and other such devices. They can be produced at low-cost using a roll-to-roll method, which is similar to the manner in which newspapers are printed.

Worldwide, scientists and engineers are endeavoring to create cost-effective production technologies to increase the affordability of solar energy.

Flexible organic solar cells demonstrate immense potential because they can be manufactured using roll-to-roll (R2R) processing method and in large quantities.

Further, they require low-cost materials in a minimal amount. However, for this to happen, the barrier layers, the transparent electrodes and in fact the entire device must be flexible.

Empa researcher Frank Nüesch leads the TREASORES project that was initiated in November 2012. This project aims to develop technologies that enable production of organic optoelectronic devices using R2R production. The optoelectronic devices include devices such as LED lighting panels and solar cells.

Recently, the mid-term review of the TREASORES project was completed. The project has achieved significant milestones. International researchers from 19 labs and five European companies have collaborated to develop a transparent, ultra-thin, silver electrode that performs better than indium tin oxide (ITO) electrodes that are currently being used in the industry.

This electrode is also lower in cost. When these transparent electrodes were used in a perovskite-based solar cell, it demonstrated an efficiency of 7% which is a record for this material. When solar cells that were manufactured using the R2R method were tested in the field, they demonstrated lifetimes that were commercially acceptable.

“The next step”, says Nüesch, “is to scale up and improve the most promising technologies identified so far, say, to produce barrier materials and transparent electrodes in larger quantities, i.e. in rolls of more than 100 meters in length."

The TREASORES project will continue development of other technologies that show promise. These include flexible, transparent electrodes that are based on carbon nanotubes (CNTs), nanowires and woven fabrics. "We are working on the most crucial issues in large-scale organic optoelectronics.

"Our new low-cost electrode substrates already outperform existing conductive oxide electrodes in many ways", says Nüesch. "But we must further improve the resulting device yields from large-scale production by reducing the defect density of the substrates."

The researchers used special instruments for conducting mechanical, optical and electrical testing of the novel materials. They were also characterized, such as for quality and lifetime of the illumination.

The flexible electrodes were produced using silver nanowires, and these demonstrated a sheet resistance that was less than 20 Ω/m2 and had an optical transmission of 80%. Ohms/square (Ω/m2) is used as a measure for electrical conductivity of thin films.

Nanowires made of copper proved to better with 90% optical transmission on glass sheet and with resistance that was less than 10Ω/m2. The ITO electrodes that are currently used demonstrate more than 100Ω/m2 sheet resistance values for such high transparency.

On these substrates having copper electrodes, solar cell devices that demonstrate more than 3% energy conversion efficiency have been produced.

When electrodes made of CNT were used, sheet resistance of 74Ω/m2 and 90% optical transmission was achieved. When researchers produced organic solar cells using these electrodes, they were able to achieve 4.5% energy conversion efficiency.

However, the electrode technologies mentioned above suffer due to waviness, roughness and also need a flattening layer that would enable optoelectronic device stacks to be deposited in a defect-free manner.

Hence, the researchers developed another electrode technology that utilized thin silver (Ag) films that were sandwiched between two layers of metal oxide (MO). Much flatter films were obtained.

The electrode stacks of MO/Ag/MO demonstrated a sheet resistance of 6Ω/m2 ohms/square having 85% optical transmission. This enabled creation of optoelectronic devices that were comparatively more efficient than other electrode technologies.

The low peak-to-valley roughness of approximately 20nm also contributes to this increase in efficiency. Organic solar cells having these ultra-flat electrodes demonstrated up to 7% record efficiencies. For harvesting light, these cells used materials that were commercially available.

The researchers used the same electrode materials for production of white light organic LEDs (OLEDs) and they achieved 17lm/W. For organic light-emitting electrochemical cells (OLECs) they achieved more than 20lm/W.

For flexible OLEC and OLED devices, these are not quite high values, hence Nüesch stressed that "all electrodes were produced by an R2R process in an industrial environment or with industrially relevant processes on large areas of the polymer substrate. We can thus say that the processes we used are robust and reproducible."