A research team led by Karl Sieradzki, materials science and engineering professor at Arizona State University, has provided new insights into the causes of stress-corrosion cracking in components employed in aircraft framework and nuclear-power-generating stations as well as in metal alloys employed in pipelines for transportation of fossil fuels, natural gas and water.

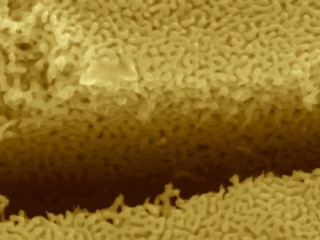

The image shows corrosion of a silver-gold alloy spontaneously resulting in the formation of nanoscale porous structures that undergo high-speed cracking under the action of a tensile stress. It helps demonstrate a discovery by an Arizona State University research team about the stress-corrosion behavior of metals that threatens the mechanical integrity of engineered components and structures

The image shows corrosion of a silver-gold alloy spontaneously resulting in the formation of nanoscale porous structures that undergo high-speed cracking under the action of a tensile stress. It helps demonstrate a discovery by an Arizona State University research team about the stress-corrosion behavior of metals that threatens the mechanical integrity of engineered components and structures

The study focuses on the interactions of metal alloys at atomic and nano levels, aiding the developments related to the prevention of the failure of systems in industrial and public infrastructure.

Sieradzki is the faculty of the School for Engineering of Matter, Transport and Energy, one of ASU’s Ira A. Fulton Schools of Engineering. The study results have been reported in a paper titled, "Potential-dependent dynamic fracture of nanoporous gold," on the Nature Materials journal website.

The team used advanced tools for ultra-high-speed photography and digital image correlation to closely monitor the events that induce stress-corrosion fracture in a model silver-gold alloy, and to observe the speed at which cracking is initiated. The cracks moving at 200mps were measured with respect to around half of the shear wave sound velocity in the material.

According to Sieradzki, the study results are remarkable considering the fact that this type of fracture can be observed only in brittle materials like glass and gold alloys are one of the most malleable metals.

The gold alloys tend to fracture under non-corrosive environment in the same way as that of children’s modeling clay. Sieradzki explained that by roll modeling clay into a cylindrical shape, it can be stretched by around 100% before breaking down. Silver selectively dissolves from the alloy under corrosive conditions, causing porosity. If this takes place when the alloy is under exposure to stress, the material tends to fracture like glass.

With the research findings, the stress-corrosion characteristics of metals like stainless steel, brass and aluminum alloys that are critical to the mechanical stability of the engineered components and structures can be understood better.

The team’s discoveries could provide a guide for “designing alloys with different microstructures so that the materials are resistant to this type of cracking,” Sieradzki said.

The Department of Energy’s Basic Energy Science program funded this research. The co-authors of the study include former and current ASU materials science and engineering graduate students, including Shaofeng Sun, Xiying Chen, and Nilesh Badwe.

References