Chemical engineers and researchers at Virginia Tech have developed a unique approach that could have a significant impact in design and discovery of future materials. This approach reveal a distinctive model that would enable quick and precise prediction of new alloy materials that could be used for efficient conversion of chemicals.

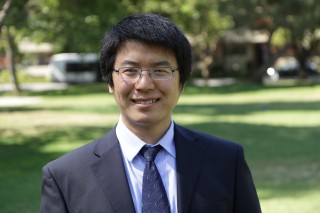

Hongliang Xin and members of his Virginia Tech chemical engineering research group, and fellow faculty member Luke Achenie developed a novel approach that should significantly accelerate materials discovery.Credit: Virginia Tech

Hongliang Xin and members of his Virginia Tech chemical engineering research group, and fellow faculty member Luke Achenie developed a novel approach that should significantly accelerate materials discovery.Credit: Virginia Tech

The paper was authored by Luke Achenie and Hongliang Xin, chemical engineering faculty members at Virginia Tech, along with Zheng Li and Xianfeng Ma, belonging to Xin’s research group.

When the addition of a catalyst speeds up the rate of a chemical reaction, the process is called catalysis. Catalysts are available in different forms, including nanoparticles, acids, enzymes, large protein molecules and solid metal.

Catalysts are used for producing 90% of the chemicals that are very important for industrial applications. Hence, the newly developed approach could have significant implications.

Xin states that, when two or more metals having accurate atomic structures and compositions are mixed, the mixture, “has shown great promise for catalyzing many chemical and electrochemical reactions.”

In previous experiments, when mixed blends of metals had been tested, they produced new physical and chemical properties. “However the process is very time-consuming and costly to search for highly optimized alloys” using the conventional approaches, Achenie added.

This is the first example of learning from data in catalysis. We anticipate that this new approach will have a huge impact in future materials design.

Xin

Hence, Achenie and Xin utilized the machine learning approach, and used existing data for training computer algorithms to predict new materials. They state that their novel approach captures complicated nonlinear molecular interactions on metal surfaces. This takes place through artificial neural networks, and hence allows exploration of alloy materials on a large scale.

Xin explained that the team focused on carbon dioxide’s electrochemical reduction on metal electrodes “because of the current interest in this process for sustainable production of fuels and value added chemicals”.

Carbon dioxide is widely used in a range of industrial applications, including carbonated beverages, oil recovery and fire extinguishers. However, carbon dioxide is a greenhouse gas, and it would be very useful to find out ways to reduce its emissions, thereby reducing global warming.

The team identified a couple of copper multi-metallics that possessed higher energy conversion efficiency and higher selectivity for electro-reduction of carbon dioxide to ethylene. In the plastics industry, ethylene is a very useful chemical.

This study opens a new way for designing metal-based catalysts with complexities, for example, geometry and composition, promoters and poisons, defects, and nano-effects.

Xin

The research group has published its findings in the Journal of Physical Chemistry Letters, a peer-reviewed journal.

References