Mar 3 2016

A mechanical sponge with enhanced efficiency for clearing oil spills requires an interconnected structure, which allows water to flow through easily. Scientists from the Istituto Italiano di Technologia (IIT), Italy, have discovered the following findings, which have been published in the 2nd March 2016 issue of the Journal of Physics D: Applied Physics.

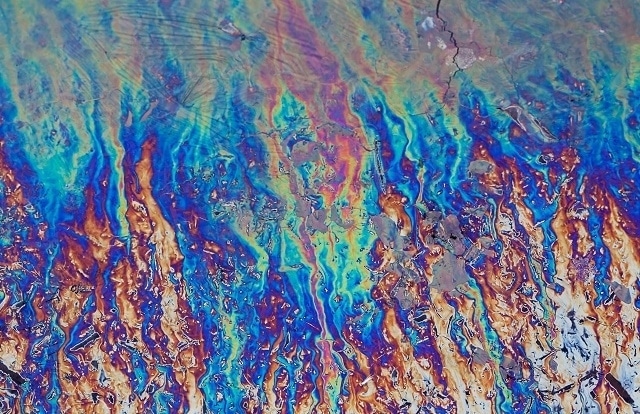

Image Credit: Mycteria/Shutterstock.com

Image Credit: Mycteria/Shutterstock.com

The standard method for clearing an oil spill involved the use of booms, followed by 'sucking' the oil present on the water’s surface. This conventional method is now being replaced with polyurethane foams that can directly sponge the oil out of the water.

We wanted to understand what the key features of such foams are, and how they can affect their performance. Particularly whether it was necessary to modify the surface chemistry, or if you could reach really good performance by simply choosing foams with the right structural parameters.

Dr Javier Pinto, Author

The theoretical and experimental study highlights the possibility of reaching absorption capacities of 30 gm of oil per gram of polyurethane, using strongly interconnected open porous structures, and pore sizes less than 500 micrometres.

Chemical functionalization of the porous structure failed to improve the oil absorption efficiency, but considerably contributed to the selectivity of the process.

It came as a surprise that there is an absence of considerations of the structure or even characterization of the foams employed in several previous studies. Understanding this is key to evaluating proposed treatments and coatings, and their effectiveness.

Dr Javier Pinto, Author

Dr Pinto assumes that the materials used for oil spill remediation can be commercialized in the near future, due to the polyurethane foam’s simplicity proposed by these materials.

Our next steps are to develop composite materials for wider water remediationThese could be low environmental impact - using materials derived from waste - and have biodegradable or biocompatible properties. We'll explore the use of these systems not only for clearing oil spills, but also other contaminants such as heavy metals or pesticides.

Dr Javier Pinto, Author

Source: http://ioppublishing.org/