Jun 13 2016

Finland-based Runtech Systems has placed its largest multi-million-euro order for high-speed turbo motors from The Switch for use in its turbo vacuum blower systems for paper machines. Using direct-drive technology developed jointly by both companies since the early 2000s, these turbos have now become widely accepted in the paper industry thanks to their superior advantages.

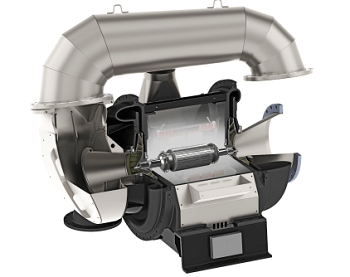

Along with being a reliable, long-lasting solution, they bring customers unmatched simplicity and energy efficiency. Years of product development and unrelenting sales work are now paying back for Runtech Systems with their unique turbo vacuum pump systems specifically designed to replace the poorly performing water ring pumps in paper mills. Runtech has superior competence in analyzing and designing efficient paper manufacturing processes. Together with The Switch, the company harnessed the built-in power of direct-drive, high-speed turbo technology to create a radical solution that has recently become the new industrial standard. The turbo vacuum blower is now a key component in the optimum solution when retrofitting existing paper machines or designing new ones.

Breaking through to standard

We’ve finally made an industrial breakthrough with our turbo vacuum blower systems, which are fully and widely accepted as a viable, long-lasting solution in the papermaking industry. Today, our customers see us a trusted and preferred supplier when it comes to providing energy efficiency.

Jukka Lehto, President and CEO of Runtech Systems.

“Another major step for us in attaining this position has been in strengthening our global sales network. We can now be in closer touch with local paper mills through our sales representatives. Although Europe still represents the largest market for us in total, China and Asia in general are growing the fastest for these products,” he says.

Exceptional savings

The undisputable main benefit of Runtech’s vacuum blower system is its power savings. Results show that mills can save between 30–60% in energy while increasing vacuum speed. Additionally, the solution is water-free, giving mills a 100% savings in water costs, which are exceptionally high in papermaking. Payback time is normally one to three years.

Environmental savings are also important benefits as regulations are becoming more stringent. A recent study proves that electrical machines can increase system efficiency as well as reduce CO2 emissions in both energy production and energy consumption.

Jukka Lehto

Simplicity facilitates uptake

“Now we have an optimum and proven solution that works at the natural speed of the blowers of up to 10,000 rpm to achieve the optimum vacuum for the process,” says Jukka-Pekka Mäkinen, President and CEO of The Switch. “The simplicity of the solution means that extra parts like the gearbox can be avoided, along with any associated cooling and lubrication. The motor offers a much smaller and lighter footprint. And it is all self-contained; only minimum on-site installation is required.”

“With Runtech, we have had a dedicated partner that truly understands the applications and complete paper mill process. Now it is exciting to see them break through with great results,” he continues. “In the future, we see that that our turbo technology can bring advantages to a wider range of industrial applications, such as oil and gas, where we already have experience with high-speed solutions.”

Latest high-performance turbo models

Deliveries of the newest motors will start in September 2016 and include higher power motors that match Runtech’s new models.

In certain cases, there has been a clear need for greater capacity. Instead of delivering five vacuum pumps for a paper machine, these new higher-performing units allow us to deliver only four. What’s more, we do not need to dimension the capacity too tightly for the prevailing conditions with these new units.

Jukka Lehto

The new turbo models are exactly the same physical size as the current ones, which enables Runtech to offer a more powerful turbo solution rebuilt for some of their existing units.