Jun 17 2016

Increasing amounts of energy are lost on a daily basis in the form of waste heat. A recent interdisciplinary project at Chalmers has discovered that a unique class of material, known as high-entropy alloys, is capable of making room for efficient heat recycling.

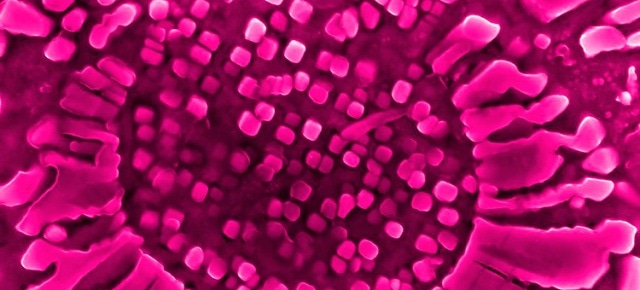

A high-entropy alloy imaged with a scanning electron microscope. ​Image: Sheng Guo

A high-entropy alloy imaged with a scanning electron microscope. ​Image: Sheng Guo

Improving energy efficiency is a significant element of the conversion to a sustainable energy system. There are huge savings to be made. For instance, less than half of the total energy content of diesel is actually utilized to power a diesel truck. The remaining energy content is lost, mostly in the form of heat. The issue of excessive waste heat is also experienced by a number of industrial processes.

This is the reason why a number of researchers are working towards producing thermoelectric materials, which are capable of transforming waste heat into energy. However, this is not an easy task. To carry out efficient heat to electricity conversion, the materials should be good at conducting electricity, but they should also have a poor heat conducting characteristic. This happens to be a contradiction for most of the materials.

One particular challenge is creating thermoelectric materials that are so stable that they work well at high temperatures.

Anders Palmqvist, Professor of Materials Chemistry, Chalmers

Palmqvist initially met Sheng Guo, a materials scientist, at an interdisciplinary workshop based on materials used for energy applications at Chalmers. Guo works with a new kind of material known as high-entropy alloys. Typically, these alloys comprise of almost five elements, which are mostly metals, at moderately similar quantities. They remain stable even when the temperatures are high, and it is also possible to control the characteristics of the alloys by changing the quantities or the components of the components.

It sounded as if high-entropy alloys could be a good new track to test in thermoelectric materials. As far as I knew, no one had done it before, so we decided to initiate a project together.

Anders Palmqvist, Professor of Materials Chemistry, Chalmers

Paul Erhart at the Department of Physics was also invited into the project, and with funding from Chalmers’ Materials Science Area of Advance, the team mutually hired a postdoc, Samrand Shafeie.

“It was an efficient model, with three research leaders who complement each other very well,” Palmqvist says.

The team developed and studied high-entropy alloys comprising nickel, iron, chromium, cobalt, and aluminum along with differing quantities of aluminum. This led to the possibility of improving the qualities that deliver good thermoelectric capabilities. The scientists arrived at a conclusion that high-entropy alloys are capable of developing into extremely good thermoelectric materials.

The results were published in Applied Physics, and the article turned out to be extremely popular in January. Editors labelled the article “exciting”.

The current task is to continue with the production of materials and understand the perfect formulation of high-entropy alloys in order to obtain optimal thermoelectric properties.

It’s a slow process, because there are many variables to play around with and a whole periodic table of elements to investigate, but with good theoretical understanding, we can try to predict which elements are the most interesting.

Paul Erhart, Department of Physics, Chalmers

The joint project turned out to be beneficial experience for the Chalmers scientists, who have actually started to think about various ways to help improve their research. These scientists have also been invited to team up with KTH Royal Institute of Technology and Uppsala University.

“Currently, the automotive industry is showing the greatest interest in converting waste heat to electricity,” Palmqvist tells us. “But if we create a really good thermoelectric material, the potential applications would expand. For example, we could produce electricity as a by-product at industries like steel mills.”

Source: http://www.chalmers.se/