Oct 21 2016

Credit: Colorado State University

Credit: Colorado State University

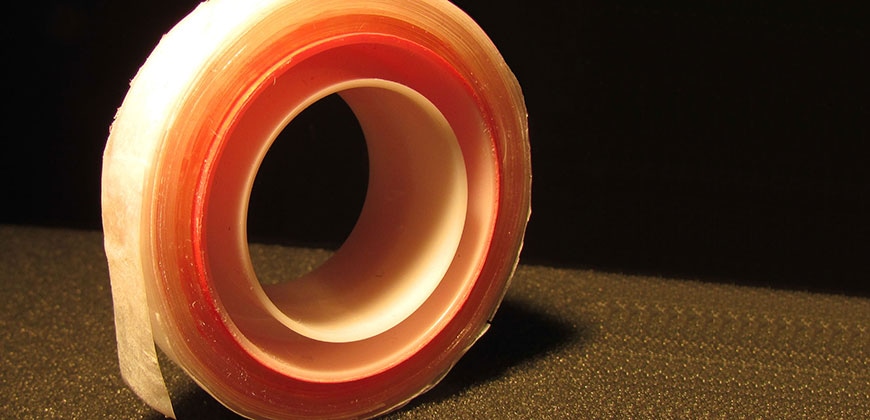

A “superomniphobic” tape that can provide liquid-repelling properties to any surface it is adhered to has been developed by Arun Kota, who works as an assistant professor of mechanical engineering in the School of Biomedical Engineering. The details of this study have been reported by the American Chemical Society.

Superomniphobic surfaces have an air cushion between a solid and a liquid surface, which makes them highly repellent to any liquid. Kota has been working on this area for over a decade, and has made numerous breakthroughs in super-repellent coatings. His latest innovation is similar to a Scotch Tape, but highly liquid-repellent.

This unique tape has been developed by Kota, Hamed Vahabi, a doctoral student, and postdoctoral fellow Wei Wang. The scientists state that although the technology looks simple at first glance, its potential impact is immense.

Simple Fabrication

Superomniphobic surfaces are not new, they have been studied by scientists since 2007. At present, these coatings can be deposited, etched, or sprayed onto any surface to attain a similar effect. However, this requires complex techniques, expensive equipment and an experienced professional.

In contrast, anyone can use the superomniphobic tape, developed by Kota and team. This makes the technology a useful solution for numerous commercial, military, and civilian applications such as self-cleaning, liquid waste minimization, corrosion resistance, drag reduction and many more.

Future Challenges

The scientists believe that the future challenges in this area are exciting, but also puzzling. Although numerous applications with superomniphobic coating have been laid out already, the task of developing mechanically durable superomniphobic coating is still a challenge.

What does the future hold for superomniphobic tape? A patent has been filed by Kota, who believes that adhesive and tape manufacturers, as well as the packing industry will be interested in their product. The team will continue their study of the mechanical durability of the tape.