Mar 6 2017

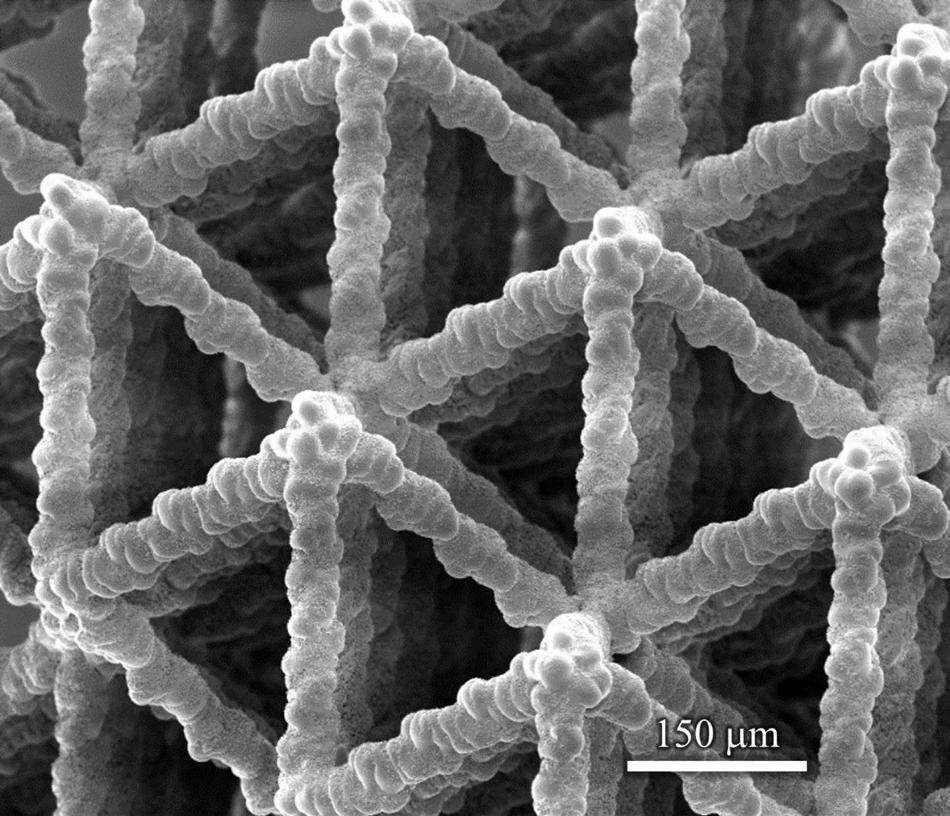

Microstructures like this one developed at Washington State University could be used in batteries, lightweight ultrastrong materials, catalytic converters, supercapacitors and biological scaffolds. Credit: Washington State University

Microstructures like this one developed at Washington State University could be used in batteries, lightweight ultrastrong materials, catalytic converters, supercapacitors and biological scaffolds. Credit: Washington State University

A unique, 3D manufacturing method has been developed by researchers from Washington State University. For the very time, this method rapidly develops and accurately controls the architecture of a material ranging from nanoscale to centimeters. The results obtained closely imitate the intricate architecture of natural materials such as bone and wood.

The researchers have presented a report on their work in Science Advances, and a patent has also been filed by them. This work has a number of high-tech engineering applications.

This is a groundbreaking advance in the 3-D architecturing of materials at nano- to macroscales with applications in batteries, lightweight ultrastrong materials, catalytic converters, supercapacitors and biological scaffolds. This technique can fill a lot of critical gaps for the realization of these technologies.

Rahul Panat, Associate Professor, Washington State University

A 3D printing method was used by the team to develop foglike microdroplets containing nanoparticles of silver and also to deposit them at particular locations. As the evaporation of the liquid in the fog took place, the nanoparticles were retained, developing delicate structures. The small structures, resembling more like Tinkertoy constructions, are porous and extremely strong comprising of a surface area that is extremely large.

The researchers used silver as they found it easy to work with. However, Panat highlighted the possibility of extending the method to various other materials capable of being crushed into nanoparticles– and almost all materials can be.

A number of attractive and intricate structures were developed by the team. The researchers also created microscaffolds comprising of solid truss members such as spirals, a bridge, and electronic connections resembling doughnut-shaped pillars or bellows.

The manufacturing method is similar to a natural, rare process in which small fog droplets that comprise of sulfur evaporate on the hot western Africa deserts and further produce desert roses also referred to as crystalline flower-like structures.

The new method uses 3D printing technology and is considered to be highly effective. Additionally, the method allows for large-scale and rapid manufacturing and produces minimal waste.

The team intends to use such nanoscale and porous metal structures for a wide range of applications. For example, the researchers are producing finely detailed, porous cathodes and anodes for batteries instead of solid structures that are currently used. This advancement will bring about a transformation in the industry by majorly increasing battery capacity and speed and also enabling the use of new and higher energy materials.

Mohammad Sadeq Saleh and Chunshan Hu are graduate students who worked on the project along with Panat.

The research conforms to WSU’s Grand Challenges initiative stimulating research in order to address some of the extremely complex issues present in the society. This research is specifically relevant to the challenge of “Smart Systems” and its theme of emergent and foundational materials.