Jul 18 2017

A new multimillion pound collaborative research project headed by BP and The University of Manchester could help to greatly minimize the impact that surface degradation processes such as corrosion and wear have on industry globally.

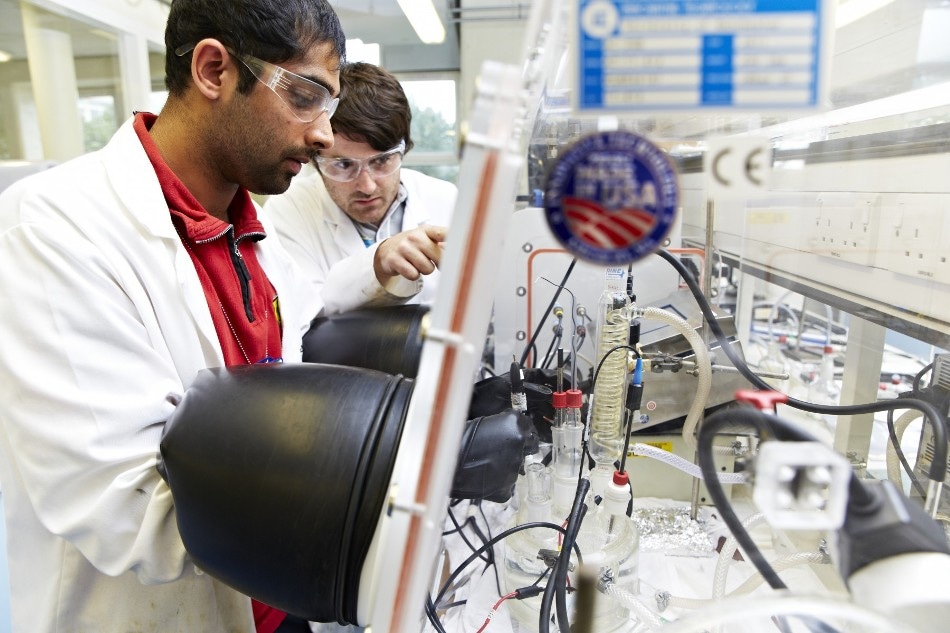

Credit: The University of Manchester

Credit: The University of Manchester

Corrosion and wear processes have extremely significant economic, societal and safety implications for industry. From machinery and tools to platforms, oil pipes and refineries, a number of industrial assets are vulnerable to these surface degradation issues. This is particularly true when they are exposed to challenging environments such as those encountered in the oil and gas sector.

According to NACE International, the global corrosion authority, it is projected that the global annual costs related to corrosion alone are more than $2Tr. Despite this large economic influence, the central processes of corrosion are not properly understood and industry depends on field experience for its management.

Although there have been impressive strides in the empirical understanding of corrosion, many of the underpinning assumptions and industrial practices date back decades.

Professor Philip Withers, the University of Manchester’s Regius Professor of Materials and the Chief Investigator on the project

But this could all transform with a new collaborative research project, ‘Preventing Surface Degradation in Demanding Environments’, funded by the Engineering and Physical Sciences Research Council (EPSRC). The project brings together top Researchers from BP, the University of Manchester, Imperial College London and the University of Cambridge, who already work together on corrosion research via the BP International Centre for Advanced Materials (BP-ICAM), plus added expertise from the Universities of Leeds and Edinburgh.

The collaborative team has received £5m of joint funding from the EPSRC and BP to analyze the processes that result in surface degradation and to form new strategies to alleviate them.

By harnessing the latest advances in computer modeling, atomic level in-situ experimental techniques and in-operando imaging and characterization; this program will focus on understanding corrosion scales and localized corrosion. Simply put, we aim to decipher the fundamental mechanisms that cause corrosion so that we can combat it more effectively in the future.

Professor Philip Withers, the University of Manchester’s Regius Professor of Materials and the Chief Investigator on the project

The funding award is part of the EPSRC’s ‘Prosperity Partnerships’ scheme which aims to support current, strategic, research-based partnerships between Universities and Business. The Prosperity Partnerships initiative is part of the Government’s wider Industrial Strategy Challenge Fund which, largely, has supported ten successful partnerships spanning 17 Universities and more than 30 industrial partners.

BP has identified surface degradation as a high priority area for future research, so we are delighted to have been awarded funding by the EPSRC to address the problems of corrosion and wear in one large collaborative project. We hope to extend the safe operational lifetimes of current materials and develop new materials which will ultimately be of great benefit to multiple industrial sectors.

Dr Angelo Amorelli, BP’s Technology Vice President of Group Research

Advanced materials - Research beacons at The University of Manchester