By Surbhi JainApr 27 2022Reviewed by Susha Cheriyedath, M.Sc.

By Surbhi JainApr 27 2022Reviewed by Susha Cheriyedath, M.Sc.In an article recently published in the open-access journal Polymers, researchers discussed the development of novel polylactic acid (PLA)-derived biocomposites by using fungal biomass.

Study: Application of Fungal Biomass for the Development of New Polylactic Acid-Based Biocomposites. Image Credit: John_Silver/Shutterstock.com

Background

Despite the fact that using petroleum-based polymers to make composites is convenient in terms of meeting the performance criteria of many applications, it confronts many significant challenges. As a result, one of the potential solutions to tackling these difficulties is the use of polymers generated from renewable resources (bio-based polymers), which may be easily disposed of or recycled after their service life without affecting the environment. PLA is one of the most promising commercially accessible biopolymers on the market, and it is employed in a wide range of engineering, scientific, and technological applications.

Fungal biomass (FB) (A) after washing/dewatering and (B) after drying/grinding. Image Credit: Asadollahzadeh, M et al., Polymers

Despite this, PLA's utility is limited due to its low heat stability, intrinsic brittleness, low impact strength, slow crystallization rate, and comparatively high production cost. The large amounts of functional groups present in fungal biomass (FB) make it a promising candidate for conversion to new operational biobased materials.

Due to its complex content, which is primarily made up of proteins, fibers, and other components, fungal mycelium biomass formed from organic residues/waste can be a suitable option for the manufacture of biobased materials. The unique property of FB suggests that it could be used as a blending component in highly sought-after biocomposites. However, no research has been conducted on the manufacturing and characterization of FB-PLA biocomposites.

About the Study

In this study, the authors discussed the utility of combining PLA and FB, a by-product of large-scale fermentation processes, in the creation of enhanced composites that adhere to the biobased circular economy concept. A micro-compounder was used to make the PLA/FB composites, which were then injection-molded after adding triethyl citrate (TEC) as a biobased plasticizer. Several methodologies were used to investigate the effects of FB with 10 and 20 wt.% and TEC with 5, 10, and 15 wt.% concentration on the thermal, mechanical, and surface properties of biocomposites.

The researchers determined impact and tensile strength values for the mechanical properties of neat PLA and the prepared PLA-based composites. Thermogravimetric analysis (TGA) was used to study the thermal degradation behavior of the neat PLA, the FB, and PLA-based composite specimens.

A differential scanning calorimeter (DSC) was used to determine the thermal properties of neat PLA and PLA-based composite specimens in a nitrogen atmosphere as the purge gas. On the tensile fracture surface of the specimens, the scanning electron microscopy (SEM) technique was used to evaluate the distribution of the FB particles in the matrix and interfacial adhesion.

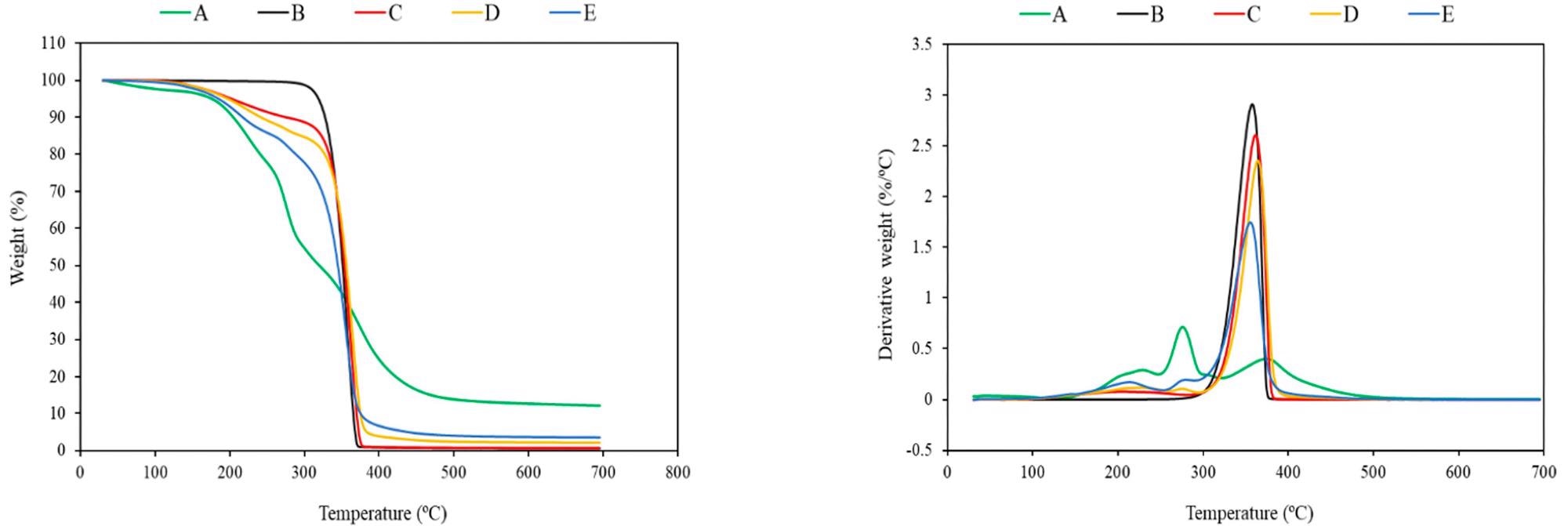

TG and DTG curves of (A) fungal biomass, (B) neat PLA, (C) PLA/10%TEC, (D) PLA/10%TEC/10%FB, and (E) PLA/10%TEC/20%FB. Image Credit: Asadollahzadeh, M et al., Polymers

The team used an optical tensiometer to evaluate the contact angles of 5L water droplets on the produced composites to estimate the wettability of the composite surfaces. The effect of adding the FB and TEC to PLA on contact angle and mechanical characteristics was evaluated by using a one-way analysis of variance (ANOVA) at a 95% confidence level. To determine the relevance of each characteristic, the p-value parameter was used.

Observations

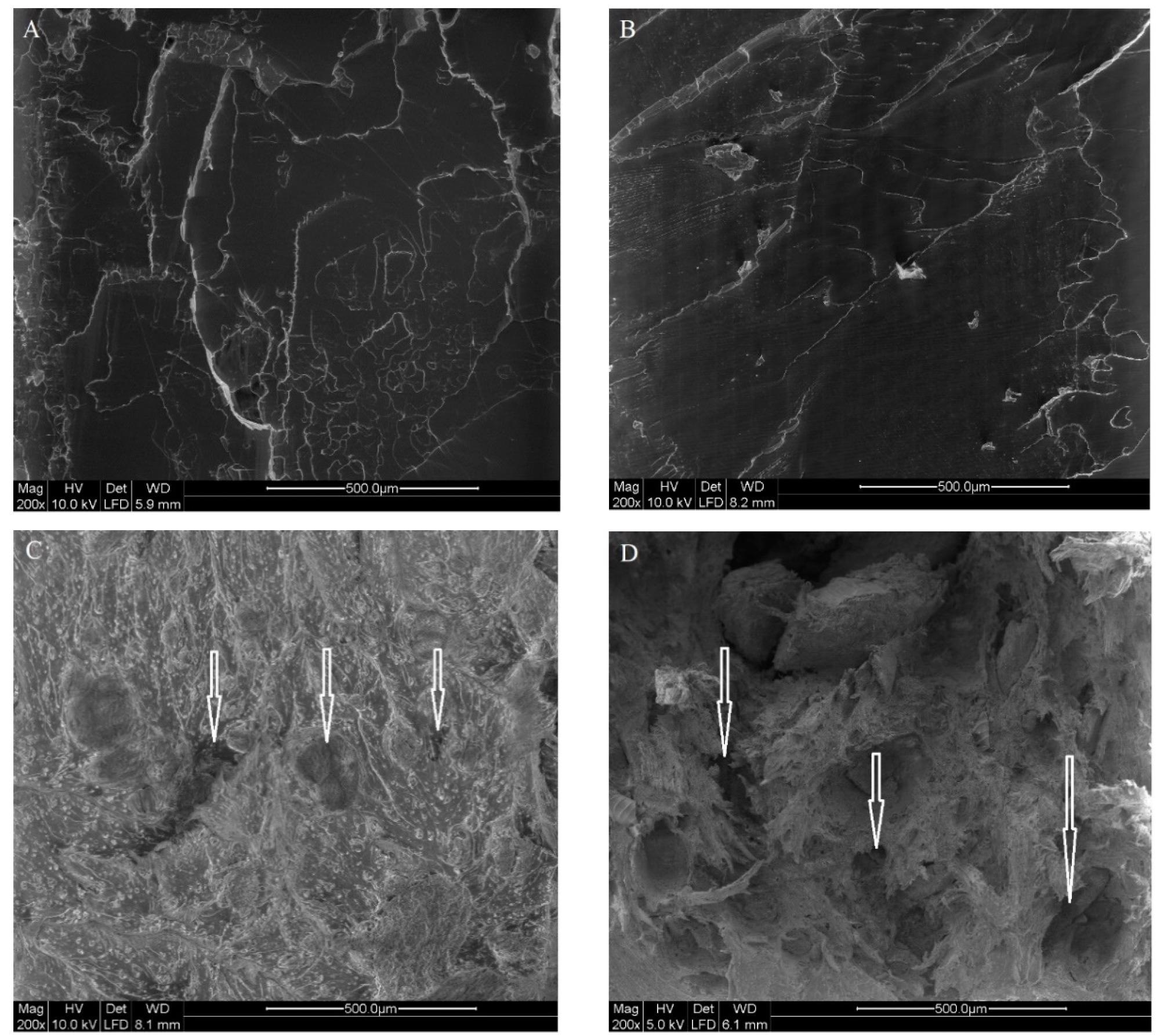

The results showed that the addition of 10% and 20% FB to the PLA/TEC resulted in a surface that was somewhat rougher and coarser. The glass transition temperature of 55.94°C was determined to be the highest for clean PLA. The temperature of 16.17°C was estimated to be the lowest for PLA/15%TEC/20%FB.

Due to the existence of diverse components in FB along with compatibility and poor dispersion between the matrix and the FB components, thermal degradation of composites comprised of FB occurred in three zones at roughly 200, 290, and 360–380°C. PLA, on the other hand, was degraded in just one step, with a maximum degradation temperature of 358°C. In addition, the PLA/TEC mixes had a faint and broad peak around 200–230°C, which was due to the breakdown of the low-molecular-weight TEC plasticizer.

In their fracture section, the PLA/FB/TEC composites had a rough surface. With increasing FB and TEC, tensile strength and Young's modulus began to decline, but elongation at break and impact strength started to increase. Elongation at break was lowest, i.e., 3.84%, and maximum, i.e., 224% in the plain PLA and bio-composite comprised of 10% FB and 15% TEC, respectively. When compared to clean PLA, the crystallization, glass transition, and melting temperatures for all blends including FB were pushed toward lower values.

Microscopic images of (A) neat PLA, (B) plasticized PLA with 10% TEC, (C) PLA-based samples mixed with 10% TEC and 10% FB, and (D) 10% TEC and 20% FB. The arrows show gaps and voids in the biocomposites. Image Credit: Asadollahzadeh, M et al., Polymers

Conclusions

In conclusion, this study elucidated that adding TEC and FB to the mix has a significant impact on the mechanical and thermal properties. The PLA matrix was shown to have no reinforcing effect; however, the addition of TEC and FB to PLA made the composite more ductile.

The authors mentioned that the current study only gives an overview of the properties of PLA-derived biocomposites, which may vary significantly depending on the starting ingredients. They also stated that to further enhance the strength qualities of the final biocomposite, future research into the influence of surface modification of FB and/or coupling agents by grafting on the adherence and compatibility among the FB and the PLA matrix is needed.

Source

Asadollahzadeh, M., Mahboubi, A., Taherzadeh, M. J., et al. Application of Fungal Biomass for the Development of New Polylactic Acid-Based Biocomposites. Polymers 14(9) 1738 (2022). https://www.mdpi.com/2073-4360/14/9/1738

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.