The quality, customer acceptance and efficacy of pharmaceutical (and nutraceutical) products, which are either ingested or applied topically to the body, for example to the skin, can be evaluated through texture analysis (Figure 1).

Figure 1. Pharmaceutical pills and capsules

Chewable, crushable, breakable or soluble medications need to break down easily in order to facilitate delivery or ingestion of dosage. Medication in the form of pills, capsules and tablets need to be strong enough to withstand handling, packaging and transportation without breaking or getting damaged (Figure 2).

Figure 2. Medication in the form of pills, capsules, and tablets need to be strong enough to withstand handling, packaging, and transportation without breaking or getting damaged.

Test Methods for the Pharmaceutical Sector

Repeatable analysis and testing methods help to evaluate the effect of changes to the formulation in an attempt to improve the suitability of a tablet for oral ingestion. With some consumers averse to taking medicines, providing preferable sensory characteristics is important to help reduce this concern.

Medications that require skin contact, like lotions, creams, powders, and ointments, bear similarities to cosmetic products in terms of their functional application, including the rate of absorption, ease of delivery, spreadability, and flow.

The sensation of touch is affected by their texture, in that smoothness and extent of oiliness affect the customer acceptance. The ease of opening the container and dispensing from it are also important considerations for medical and health products.

Compression

The hardness and resistance to damage exhibited by tablets while being packaged or transported, and the ease to crush of pulverizing for ingestion, can be evaluated by measuring the required compressive force (Figure 3).

For ointments and creams, their ease of application and spreadability can be evaluated through compression testing.

Figure 3. Tablet crush

Extrusion

Extrusion testing is generally used for semi-solid pharmaceutical formulations (Figure 4).

Forward and backward extrusion methods can be used for evaluating characteristics like consistency, flow, spreadability, and viscosity. For alternative formulations, it is essential to ensure consistent dispensing rates and forces.

Extrusion testing can also be used to evaluate the ease of application and spreadability of hair waxes, moisturizers, pastes, and masks. The dispensing effort of gels, shampoos, and creams can be evaluated by forwarding extrusion.

Figure 4. Extrusion testing is generally used for semi-solid pharmaceutical formulations.

Penetration and puncture

The hardness of solid tablets or lozenges can be tested through penetration and puncture testing by using needles or cylinder probes with narrow diameters (Figure 5).

The bite force and crush resistance of lozenges or tablets can also be assessed. For throat lozenges that are dissolved in the mouth, the rate of softening is evaluated.

Figure 5. Hard lozenge penetration

Shear, snap, bend and break

The effort needed to break large tablets or tablets with a scored line or indent for easy snapping can be evaluated through snap, bend and break tests.

Figure 6. Tablet snap

Tension

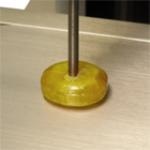

Tension testing can be used to evaluate the stickiness of ointment and creams (Figure 7).

Figure 7. Stickiness assessment of creams and ointments

Gel testing

Gelling agents are used in some pharmaceutical and nutraceutical formulations in place of creams because of their gel-like properties.

Their strength can be evaluated by following the standard tests prescribed by the gel industry for testing the raw ingredients or final gel product. Bloom strength testing may also be performed to evaluate gel products.

Figure 8. Gel testing

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.