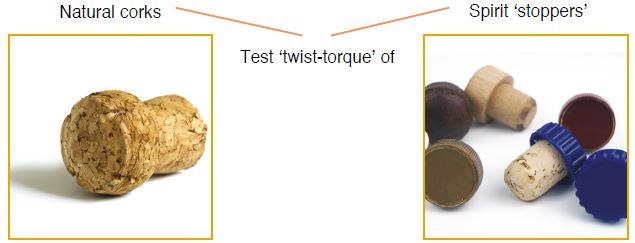

Natural corks need to execute several important functions within the champagne and sparkling wine industries in order to meet consumers’ expectations and also to guarantee the quality of the drink. The continuous increase in pressure and new breakthroughs from alternative closure manufacturers have made it all the more important for wine and cork producers to ensure seal integrity and cork quality, and at the same time, to maintain reasonable access to the bottle.

Force and torque testers available from Mecmesin allow users to measure cork performance by easily and rapidly determining the extraction force.

“Combi” Cork Extraction Tester

The “Combi” cork extraction tester is a single system that enables testing cork to cut down the difficulties associated with poor cork quality. Not only does the system determine the release twist-torque of a spirit bottle stopper or a champagne/sparkling wine cork but also measures the extraction pull-out force of a standard still-wine cork.

The “Combi” cork extraction tester was developed in association with and endorsed by Oeneo Bouchage — one of the leading cork manufacturers in the world. It allows users to:

- Establish a reliable standard of product quality

- Assess cork seal integrity to reduce cork taint

- Improve cork design while still enabling easy opening

Benefits

- Replication of helical twist and pull motion

- Clear, immediate display of relevant effort; torque, force

- Pneumatic clamping for efficient and quick testing

- Accommodates a wide range of standard bottles

- Repeatable, quantified, calibrated results

- Perform CIVC-recommended testing (for Champagne)

- Intuitive controls guarantee easy set-up and simple operation

- Continuous speed ensures reproducible results and high accuracy

- Visual and audible alarms help identify out-of-tolerance results quickly

- Effective grips ensure rapid and efficient testing

- Suitable for use in a production environment that has integrated safeguards to protect the system from spillage

Test extraction force of natural and synthetic corks

Functionality for sparkling wines

The CombiCork-dV provides a helical motion to simultaneously pull and rotate the cork from the bottle at a constant pre-set speed; the Champagne and sparkling wine industry's standard of 60 rpm and 900 mm/min. The relevant opening effort of peak torque is displayed in N.m.

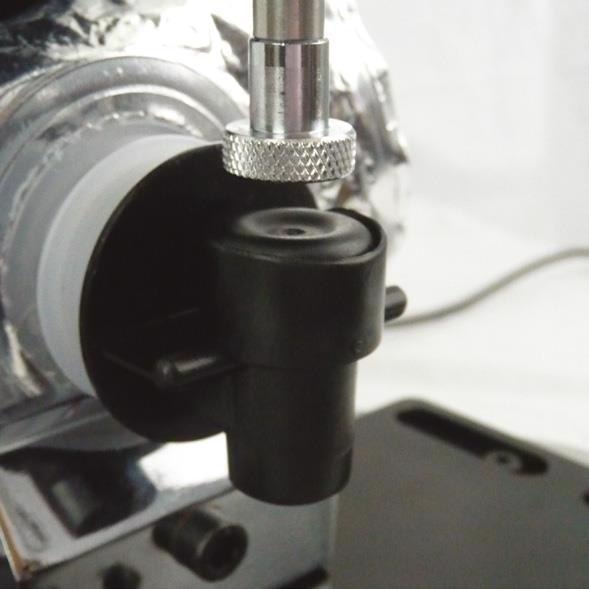

Sparkling wine bottles are held in place by a set of 4 interchangeable rubber-faced jaws. These are clamped against the bottle via a pneumatic chuck; the preferred option as it provides faster operation and is ergonomically easier to use for the operator. A manually-operated vice can be specified.

Using simple controls the bottle is then raised to a pre-set stop where the cork can be inserted into the upper grip. The wire cage (muzzle) is then cut to release it before testing. The bottle is then lowered by the tester at a fixed speed whilst the release torque of the cork is captured on the display unit.

A stainless steel drip tray catches any liquid spillages whilst a safety guard protects the operator from any risk of splintering glass.

“CombiCork-dV” adjustable pneumatic bottle grips

Functionality for still wines and spirits

The CombiCork-i tester is expanded to extraction test capsulated corks, including ‘bar-top’ and ‘Altop’ varieties; universally used as spirit bottle closures. As spirits do not generate the internal pressure of a sparkling beverage, the stopper is not forced outwards by the pressure. This means that the extraction force to pull out the cork (measured in daN) is of equal relevance as the release torque (in N.m).

The CombiCork-i is equipped with a load sensor and software package which monitors both extraction force and release torque. Cyclic testing can also be performed—extracting and re-inserting the closure repeatedly—simulating real-world usage. This allows manufacturers of capsulated corks and producers of spirits to monitor the true performance of these stoppers and control their quality accordingly.”

Combi-i extraction test on whisky stopper

Manual Torque Tester

Manual torque tester is a simple, cost-effective, handheld instrument ideal for carrying out routine and rapid spot checks of cork extraction forces for sparkling wines and champagnes.

With the help of the Mecmesin “Smart” torque sensor and dedicated cork gripping accessory, a manual twist-action is applied to securely release the cork. This allows the sensor to determine the torque needed to initiate the rotation of the cork, which is shown and recorded by a digital display available from Mecmesin.

As a responsible supplier we are committed to ensuring safety within our products. The solution provided by Mecmesin means we can monitor the extraction force of our corks to guarantee our customers receive a consistent end product.

Frédéric Junge, Oenologist-Quality Manager, Sibel SA—Oeneo Subsidiary, France

Still Wines

Motorized Cork Extraction Tester

Mecmesin’s motorized cork extraction tester is perfect for conducting simple cork extraction tests on both synthetic and natural still-wine stopper corks. It is a highly accurate and low-cost force measurement system designed to meet the ISO 9727 requirements.

- Optimized cork design to guarantee ease of opening

- Helps monitor the integrity of cork seals

- Test to NFB 57-100 and ISO 9727 standards

The system integrates a cork extraction test rig, which is capable of accommodating bottles of different heights, making sure they are firmly held at the time of the test.

The test is performed by applying a tensile load at a constant rate of 300 mm/minute, until there is a rapid drop in resistance, or the cork is fully removed from the bottle. Clearly shown on Mecmesin’s digital force gauge, the peak extraction force can be printed for additional evaluation.

Benefits

- Continuous speed ensures reproducible results and high accuracy in accordance with ISO standards

- Rapidly identifies whether there is likely to be an issue in the configuration of corks/bottles

- Simple operation — a test can be performed with a single push of the button

Evaluate Results Further

Producers of wine and cork can obtain additional information with respect to the performance of cork test and identify critical measurement values with the help of Mecmesin’s data acquisition software. Through VectorPro Lite software, each test can be graphically traced to be shown, ready for detailed analysis of results.

- Test can be viewed “live” on a PC screen

- Performance can be quantified by performing multiple calculations

- Pass/fail scenarios are clearly indicated by color-coded results

- Reports can be printed or results can be exported for additional analysis

ISO 9727 Standard

ISO 9727 is an international standard that specifies the reference techniques for establishing, among other aspects, the cylindrical stoppers’ extraction force. An excerpt from the standard with regards to the test procedure is shown below:

- Fix the bottle with the corkscrew to the moveable base of the press, using the fixing device

- With the connecting device, connect the triangular handle of the corkscrew to the sensor of the press

- Start the press, with its moveable base, at a speed of 30 cm/minute

- Read the extraction strength on the measure and control unit

Fixtures

Dedicated cork extraction fixtures offered by Mecmesin make it easy to set up and perform the test operation.

Cork Extraction Test Rig

- Test stopper corks range between 28 and 35 mm in diameter

- Bottle cradle equipped with an anti-slip surface can be easily modified to accommodate bottles of different heights, for example, 200–750 mL

Corkscrew Test Accessories

- Profile of corkscrew supplied suits testing of synthetic or natural cork

Metal Screw Closures

Over the past several years, wine bottle closures have undergone significant changes. Bottlers and winemakers no longer prefer cork as the closure of choice and are increasingly adopting the ease of the aluminum screw-on cap, like the “Stelvin.”

The range of test equipment from Mecmesin can assess the application of screw caps and release torque to:

- Determine consistency of release torque directly from the production line

- Reduce risk of leakage and oxidation caused by poorly fitted screw caps

- Make sure that the capping machine is set properly to prevent any damage to closures

Manual Closure Torque Tester

The manually operated closure torque tester — Orbis — is a simple and low-cost device. It allows effective and rapid in-line assessment of screw closures, scrutinizing that the capping heads are steadily applying the right levels of torque to make sure that a hermetic seal is retained by closures.

Orbis

Benefits

- Portable and lightweight

- Lockable to N.m and lbf.in

- Convenient operation with a large-digit display to display the highest opening torque value

- Accommodates bottle diameters ranging between 10 and 190 mm

- RS232 output for exporting results to PC or printer

- Water-resistant design rated to IP54

The Orbis is rated to 6 N.m (50 lbf.in), making it very easy to set up and operate. There are four gripping pegs that safely hold the base of bottles, set for manual application of torque. The Orbis features a fast sampling rate and provides accurate release torque measurements. It is sufficiently robust to be used directly within the wine production environment.

The success of the introduction of screw cap closures in the wine industry can be attributed to the successful application of the closure itself. In order to determine a good application you require reliable, accurate and consistent testing equipment. The Mecmesin closure torque testers have fulfilled all the criteria and have given us great confidence in our application of the screw cap closures.

Dean Zeunert, R&D Technical Manager, Orlando Wyndham Group

Wyndham Group produces Jacob’s Creek wine in the Barossa Valley.

Motorized Closure Torque Tester

Vortex-dV — a motorized torque testing solution — acts as an affordable test platform for determining the application as well the release torque of screw closures to ensure easy openability and to validate that correct torque levels are being applied.

Since the Vortex-dV is driven by a motor, it eliminates the variability in results usually associated with manually operated testers. It also comes in many different capacities ranging from 1.5 to 10 N.m (13–90 lbf.in).

Vortex-dV motorised torque tester

The Mecmesin Vortex gives us peace of mind that our process is in control on screw cap application. Our production line does half hourly checks for measuring the seal torque and the bridge torque. The Mecmesin Vortex is a great instrument for us.

Mr Ian Scrivener, Technical Manager Packaging, Hardy’s Wine Company

Split Mandrel Stelvin Grip

The split mandrel Stelvin grip — specifically developed for carrying out motorized torque tests — employs a split mandrel design. The grip can be easily placed on a motorized torque test system for fastening around the closure and offers the additional reassurance of firmly holding it in place without the risk of slipping or pinching.

Benefits

- Consistent test measurement can be made through anti-slip rubber-lining

- Optimum accuracy is achieved through maximum surface contact with closure

Check the Spring Rollers on the Capping Head

It is important to set the spring-loaded rollers on the capping head to make sure that metal closures are applied properly. An inadequate force will result in a poor fit, while surplus force will damage the closure.

The 200 N Compact Force Gauge+ (CFG+) offered by Mecmesin is an affordable handy tool that can be used for checking the rollers quickly and routinely.

Benefits

- Portable

- Easy to operate

- Peak force is frozen on the display

Innovations in Wine Packaging

To preserve the condition of the end product, good packaging is very important. Today, spirits and wine increasingly come in a wide range of novel packaging such as plastic bottles, cans, cartons, and pouches.

Force and torque test equipment provided by Mecmesin has the required flexibility to carry out several different application tests on a wide range of packaging.

Bag-in-Box

Several functions are performed by components of bag-in-box wines. The packaging itself should be able to resist crushing when stacked, stored, and shipped. The tap dispenser, often known as Presstop, Flextap, or Vitop, should be adequately sealed to the foil pouch to prevent leakage and allow users to dispense the contents by simply pushing the tap button.

Actuation force of tap dispenser

A compression test carried out on the tap button will assess:

- The force applied to activate the dispenser

- The smoothness and ease of activation, guaranteeing correct functionality of mechanism

A tensile test is carried out to check the strength and quality of the adhesive bond between the bag and dispenser fitting. This will allow:

- the assessment of adhesive application

- the ability to retain the right seal and reduce any risk of leakage

Tensile strength of sealed joint

Ring Pull Closures on Cans

An adequate level of tensile loading should be tolerated by ring-pulls to open the container, without breaking away from the lid. By performing a simple tensile test on a ring-pull, the quality and fitness-for-purpose of the ring-pull mechanism can be assessed.

PET, Tetra Paks, and Cans

Top-Load Testing

Top-load testing is important to maintain and ensure the integrity of product packaging during the manufacturing process, during storage and stacking, and finally during shipment.

Top-load, also called crush testing, determines the resistance of a sample to a compressive load. Its main value is to make sure that containers can tolerate the axial load applied at the time of the capping process. Top-load testing systems from Mecmesin allow users to measure:

- Container-free height

- The maximum compressive load, which can be tolerated by a container

Benefits

- Reduce material usage — downgauge for cost savings — and, at the same time, maintain the product strength

- Improve package design to boost production volume and efficiency

- Fulfill environmental standards

Plastic Screw Cap Closures

The plastic screw cap — mainly used on Tetra Paks and pouches and plastic wine bottles — should offer an impermeable seal to prevent oxidation, thus maintaining the wine’s quality but still enabling users to open the product without any major difficulty.

Mecmesin torque testers serve to:

- Establish the peak torque needed to open a screw closure

- Make sure that a consistent level of torque is applied by the capping machine in order to reduce damaged closures

- Determine slip-torque and bridge-torque of tamper-evident closures to establish effective closure performance

The Mecmesin Orbis has helped us immensely with the introduction of screw cap closures. We love this unit because it is robust and easy to read on the large LCD display. This unit has been an integral part in testing screw cap closures; it has several times traveled with me to all corners of Australia. We chose the Mecmesin Orbis because of its reliability and robustness. It is great value for money especially compared to the old analog units.

Andrew Wright, Operations and Logistics Manager, CSA Australia

CSA Australia supplies all kinds of wine closures.

Gift Packaging

Luxury wines and, especially spirits, are generally presented in gift packs consisting of a cardboard tube equipped with metal lids as stoppers. An important measure of quality involves making sure that the metal lid fits tightly to the cardboard tube so that the bottle does not fall out but not so tightly that the consumer cannot gain access.

The highly effective “lid-removal tester” from Mecmesin works by entering the metal lid and determining the peak tension force needed to pull it off.

Lid removal test

Wine Labels, Container Seals, and Adhesive Bonds

Peel Testing

Peel testing is used for determining the strength and behavior of heat-sealed or glued seams on plastic or foil packaging. It enables a quantifiable assessment of whether a consumer is able to easily open the package without tearing completely so that the contents spill out easily.

Mecmesin’s tensile testing system allows routine measurement of seals and labels to establish the force needed to start and propagate a peel on adhesive bonds and container seals.

Peel test of induction-sealed foil tab

Benefits

- Production procedures and machine settings can be optimized to guarantee adequate and correct application of adhesives

- Easy opening by end users is ensured without affecting the seals’ usability and quality

Packaging Materials Used Within Form-Fill-Seal Converting Machinery

Coefficient of Friction Testing

Since the winery industry uses several different packaging materials, it is important to improve the processes to maintain an effective production.

Form-fill-seal converting machinery is required to feed, move, stretch, shape, weld, cut, and apply a tensile load to raw packaging materials at extreme speeds. The coefficient of friction tests these materials’ surface roughness or slip properties to make sure that each action can be easily performed without affecting the efficiency of the converting process.

Benefits

- Equipment running speeds can be optimized to streamline production

- Risk of damaged products or materials of poor quality being manufactured can be reduced

- Test to standards — BS EN ISO 8295, ASTM D 1894

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.