There are large performance advantages potentially offered by scramjets (supersonic combustion ramjets) over rockets for high-speed propulsion. There remain significant barriers to the routine deployment of scramjets for access-to-space or high-speed travel.

Image Credit: Shutterstock/Marc Ward

Inlet unstart is a particularly critical issue associated with scramjets. That is the upstream displacement or disgorging of the original inlet shock system. Large flow spillage can be caused by the resulting detached shock that forms in front of the inlet, which will reduce performance, and cause the production of violent, unsteady loading on the engine, potentially leading to its destruction.

Abnormal operating conditions inside the combustion chamber of the engine is one potential cause of inlet unstart. This would lead to the upstream propagation of pressure disturbances, which can displace the inlet shock system. As an example, the failure of the second X-51 flight was said to have been caused by such a process.

Therefore, it is necessary to examine the responsible mechanisms inside the combustion chamber, and understand how the transient phenomena that accompany incipient unstart may manifest themselves to predict, detect, and prevent such unstart events.

Experimental Configuration

All of the experiments were carried out at the German Aerospace Center (DLR) within the HEG (High Enthalpy shock tunnel Göttingen) facility - a reflected-shock wind tunnel, capable of reproducing a wide variety of flow conditions at Mach numbers from approximately 6 to 10.

The facility limits the test time to a few milliseconds, allowing the study of a range of high-speed flow problems but making visualization, particularly of unsteady phenomena, especially challenging.

In the present study, the model configuration is a full-scale reproduction of the fuelled flow path of the HyShot II flight experiment, the first successful test in the HyShot program, run by the University of Queensland, Australia.

The program was designed to generate reference supersonic combustion data at hypersonic Mach numbers. As such, the configuration is more academic than a practical thrust-producing engine. However, the Hyshot II was considered an ideal candidate for this study due to the simple design and convenient optical access.

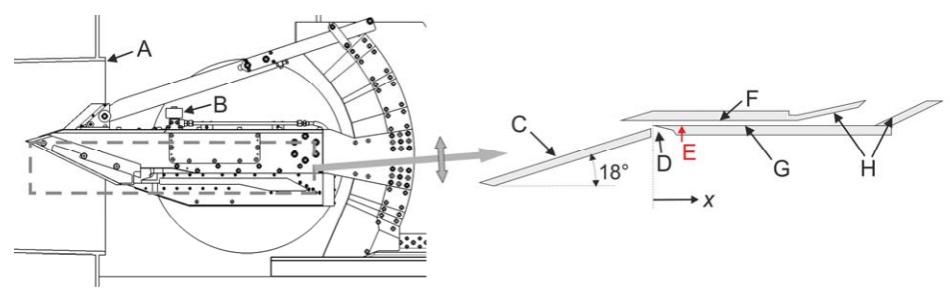

The right-hand side of Figure 1 shows the flow path. The intake consists of a simple 18º wedge. The boundary layer from this surface is swallowed by a boundary-layer bleed channel, as opposed to being allowed to enter the combustion chamber. The combustion chamber is a constant-area duct of 300 mm length, 9.8 mm height and 75 mm width.

Around 58 mm downstream of the intake-side leading-edge hydrogen fuel is injected in the wall-normal direction through four port-holes. A simple two-dimensional expansion makes up the exhaust. The left side of Figure 1 shows a schematic drawing of the model inside the HEG test section.

In these experiments, the flight conditions of the HyShot II flight experiment at 28 km altitude were reproduced with the wind tunnel. The free-stream Mach number was approximately 7.4. To induce both steady and unsteady combustion conditions, hydrogen fuel was injected at various pressures.

Figure 1. (Left) Schematic drawing of the HyShot II scramjet model in the HEG test section: (a) HEG nozzle; (b) valve for hydrogen injection. (Right) Flow path for the HyShot II scramjet (upside-down relative to the left schematic): (c) intake ramp; (d) boundary-layer bleed channel; (e) injection location; (f) cowl-side combustion chamber wall; (g) injector-side wall; (h) exhaust surfaces. Image Credit: Cavitar.

Visualization of the flow and combustion features was an important component of this study. As such, to provide optical access to almost the entire combustion chamber, windows were installed in the model.

Schlieren with a conventional Z-type arrangement was the first type of imaging implemented. The first spatial derivative of the flow density is visualized with the Schlieren technique, making it useful for imaging features such as shocks, boundary layers, and shear layers incompressible flows.

In facilities such as HEG, high-speed Schlieren imaging is challenging due to the short test times and the significant amounts of self-luminosity created by the hot gases in the test flow. There is potential for the light source to be overwhelmed by this luminosity.

The luminosity problem is aggravated further if, like in this case, the flow is combusting. This issue was overcome here by using CAVILUX Smart illumination laser for visualization. This is because it was possible to insert a narrow band-pass filter in the light path due to the monochromatic nature of the light produced, which effectively removed the self-luminosity.

The speckle and diffraction edges typically associated with laser light sources were also eliminated with the incoherent nature of the light. The short pulse duration (here ~30 ns) was another advantage of this light source, as it effectively freezes the flow structures. The CAVILUX Smart was employed in combination with a Shimadzu HPV-1 high-speed camera, with frame rates of 16 or 32 kfps.

OH* chemiluminescence visualization was the second type of imaging, also using the Shimadzu HPV-1 (without a light source). During the combustion of hydrogen OH is one of the intermediate products and, as such, the concentration of the electronically excited radical, OH*, can provide a good indication of the onset of the flame.

A further advantage of OH* is that it emits strongly over a narrow wavelength band (near 310 nm). This means that if a narrow band-pass filter of this wavelength is placed in front of the camera, line-of-sight intensity distributions of this radical can be obtained. Links between the flow and combustion features seen inside the combustion chamber can be drawn by combining Schlieren and OH* chemiluminescence visualizations.

Results

Low hydrogen injection pressures resulted in the development of steady combustion conditions inside the combustion chamber.

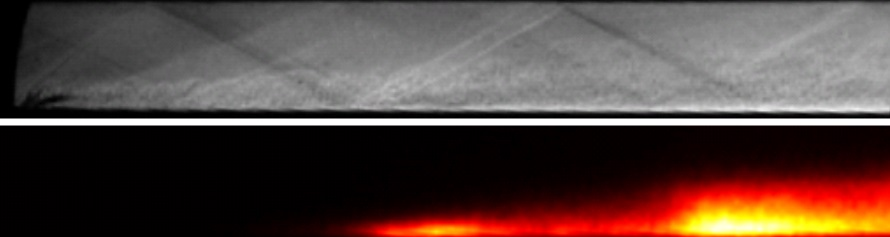

Schlieren and OH* visualizations of the flow region close to the injection location (approximately 80 mm long) are shown in Figure 2.

Figure 2. (Above) Schlieren image of the flow in the HyShot II combustion chamber near the injection location (seen at the bottom left corner) for steady combustion conditions. (Below) OH* chemiluminescence image of the same region. Image Credit: Cavitar.

In the lower-left corner of each image are the injection port-holes. In the Schlieren image, the barrel shock created by the interaction of the injected hydrogen with the incoming test-flow is clear to see, along with several of its reflections down the duct.

Also visible are the injection jets themselves; there is a good indication of the freezing of the turbulent structures by the short laser-pulse duration.

Application notes on the R&D Combustion Schlieren imaging Cavitar Ltd can be found here: www.cavitar.com.

There is an approximate penetration depth one-half of the duct height by the downstream end of the visualization window. There is no evidence in the OH* image of combustion taking place directly at the point of injection. Instead, it seems that combustion is initiated near to the injector-side wall by the first reflection of the barrel shock.

As such, there seems to be a sufficient increase in the temperature and pressure across the shock to bring the hot hydrogen in the boundary layer at the sides of the injection jets to ignition conditions. Up until the second reflection of the barrel shock, combustion remains isolated to the boundary layer. This “kicks” the flame further out into the duct and intensifies combustion. Therefore, a clear link is shown between the flow and combustion features in these images.

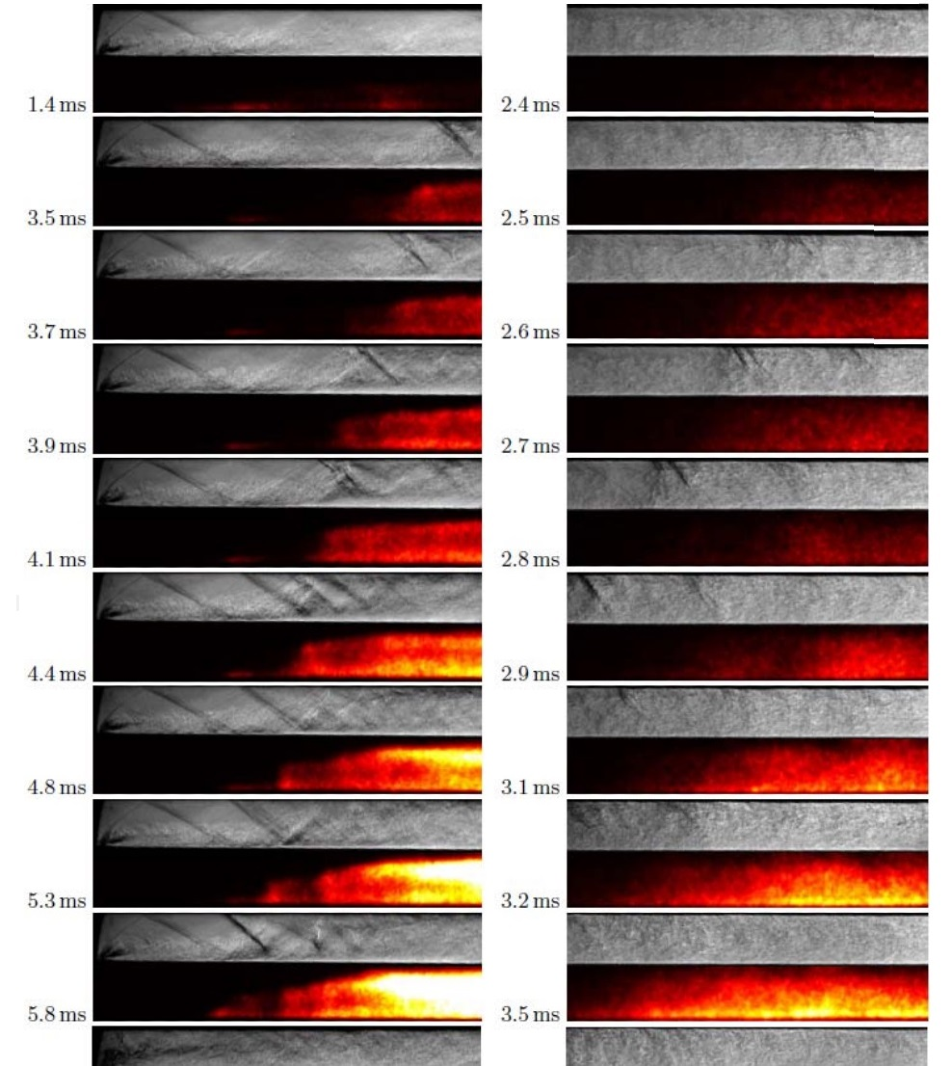

Figure 3. Quasi-synchronous Schlieren and OH* chemiluminescence visualizations of the transient flow (near) near the injector and (right) in the central combustion chamber. Image Credit: Cavitar.

It was noted from pressure transducer measurements that a pressure disturbance began to develop and propagate upstream as the amount of injected hydrogen was increased, which signaled the onset of unstart. It was unclear as to what the nature of this disturbance was and, as such, high-speed visualizations were captured of the unsteady development. Figure 3 shows sequences from these.

A sequence of the flow region close to the injection location is shown in the left column. In the initial 1.4 ms it can be seen that the picture is similar to that of the steady combustion case. The apparent weakness of the observed combustion is explained by the fact that the exposure time for the OH* image is reduced here.

A shock structure is first seen on the cowl-side wall in the Schlieren image at 3.5 ms, with an accompanying bulging feature in the OH* image. These continue to move upstream, until around 4.4ms when a quasi-steady configuration arises.

Just downstream of the injectors, the shock is lodged on the cowl-side wall and located immediately downstream of the impingement point of this shock on the injector-side wall is the main combustion region. The development of a separated flow region on the injector-side wall is suggested with the appearance of the OH* structure as it moves upstream.

The increased residence time in such regions greatly enhances the hydrogen ignition. This interpretation is also supported by unsteady flow structures in the Schlieren images. By 7.0ms, the shock structure continues moving upstream past the injector. However, as this is after the steady test time it could be a result of the unsteady inflow conditions that subsequently develop.

Corresponding images from the central combustion chamber further downstream are shown on the right-hand side in Figure 3. A shock train on the cowl-side wall has developed and is visible from 2.5 ms; this shock train quickly strengthens and moves upstream.

In scramjet combustors, such shock trains usually result from one of two mechanisms: boundary-layer separation caused by the adverse pressure gradient, or thermal choking caused by excessive heat release driving the flow to sonic conditions.

The gradual intensification of the combustion is seen in the OH* images. However, an OH* feature that follows the shock train motion is notably absent, suggesting that the shock-train development is not associated with layer separation, but is instead a result of thermal choking. This contradicts the findings of previous investigations into this configuration. The boundary-layer separation seen in the upstream sequence must, therefore, develop at a later point in the propagation of the shock train.

Conclusions

The unsteady flow and combustion phenomena leading up to unstart in a model scramjet engine were investigated through high-speed Schlieren visualizations using CAVILUX Smart laser and OH* chemiluminescence imaging.

Incipient unstart seemingly took the form of a shock train that began in the central combustion chamber and propagated upstream. The boundary-layer separation was ruled out as the primary mechanism for this unsteady development by comparing Schlieren and OH* images. The responsible mechanism was therefore identified as thermal choking due to excessive heat release.

Acknowledgments

Produced from materials originally authored by Stuart Laurence (Ph.D.) from the German Aerospace Center (DLR), Göttingen.

This information has been sourced, reviewed and adapted from materials provided by Cavitar.

For more information on this source, please visit Cavitar.