Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

The World’s First Dual-Beam System

In 1993, Thermo Fisher introduced the world’s first dual-beam system, the DualBeam 620. This new instrument combined focused ion beam and scanning electron microscopes into a single platform.

Francis Morrissey, Senior Account Manager at Thermo Fisher Scientific, first worked with the dual beam system after being introduced to it by Dr. Richard Wirth from GFZ Germen Research Centre for Geosciences, Helmholtz Centre Potsdam.

Dr. Wirth brought along a pre-thin sample, which is 100 microns thick and stuck on a little copper grid. It had all these small olivine inclusions in a substrate, and he wanted me to try and thin down this section and capture one of these small inclusions - which he was expecting to be diamond - within that thin section.

Francis Morrissey, Senior Account Manager at Thermo Fisher Scientific

He immediately came across a few issues as olivine is an insulator, so as it is thinned out, its start to produce charge. This was not ideal, so he decided to try an alternative method.

“I turned a small 3-millimeter grid on its side, stuck it in the microscope, and started preparation for an ex-situ lift-out instead.”

Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

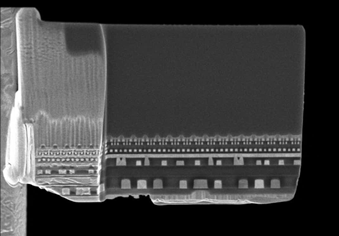

Thin sections could be seen on the surface, and each one was where Morrissey attempted to thin down on a diamond inclusion. Once lifted out, he immediately got his results, and this was the first time that results were obtained from this method.

This ex-situ lift-out, therefore, meant that a particular feature – such as the little inclusions of a diamond – could be obtained and that it could be thinned out in a more consistent manner rather than the pre-thinned.

There was no other way for Dr. Wirth to obtain these results, therefore this was his justification to get funding from his scientific body to go ahead and purchase a microscope to carry out this task.

The Industry-Wide Adoption of TEM Sample Preparation

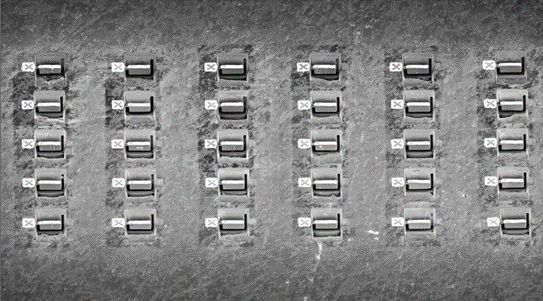

As both industry and academia began to adopt TEM sample preparation using dual-beam systems, there became a demand for higher throughput. In 1998, Thermo Fisher addressed this need for automation with the first-generation AutoTEM Software.

The FIB has now taken over sample preparation for TEM and a lot for cross-sectional analysis with SEM. This meant that TEM operators were no longer sitting around waiting for the best sample to come around. As a result, there was time to branch out into other material types, such as polymer materials.

Thermo Fisher Scientific has always been at the forefront of automation, and this really made a difference in throughput and the company’s ability to keep up with sample demand.

AutoTEM Software and Its Impact on Industry

Thermo Fisher Scientific’s second generation of automation software for TEM sample preparation of was established in 2007. The integration of a graphic user interface significantly enhanced ease-of-use, especially for new operators.

Inverted sample preparation also began to become popular in 2009, and was frequently used by dual-beam instruments to mitigate the curtaining effect during sample preparation.

Thermo Fisher Scientific also introduced the first fully integrated nano-manipulator, EasyLift, in 2011, with motorized rotation for consistent in situ preparation of high-quality ultra-thin TEM lamellae.

EasyLift was fully controllable inside the dual-beam graphical user interface, enabling faster and easier sample preparation.

These advances in the instruments, techniques and software answered the call of multiple industries to help keep up with the rapid pace of technology. For example, the development of dual-phase steels for lighter and cheaper automotive bodies, clean energy solutions with solar cells, new generation batteries and energy storage, smaller and more economical semiconductor devices, and lighter and stronger composite materials for the aerospace industry, to name a few.

David Foord, Director of Product Marketing, Thermo Fisher Scientific

Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

In 2016, the Phoenix FIB column delivered breakthrough technology with unprecedented low kV FIB performance for the highest quality TEM sample preparation. In 2019, AutoTEM 5 revolutionized automated sample preparation for users of all skill levels. It was the first time fully automated sample preparation, including in situ lift-out with the EasyLift manipulator, was commercially available on the Helios DualBeam for all materials.

Now, anyone, not just the highly skilled operators that typically operate these machines, can reliably produce high-quality ultra-thin TEM samples on a dual beam.

Finally, Thermo Fisher Scientific also introduced the world’s first commercial instrument with fast switchable, multi-ion species PFIB source back in 2019. The Helios Hydra DualBeam allows the user to tailor the ion species for specific material and application needs to optimize processing conditions and achieve the highest quality results for a broad range of materials with xenon, argon, oxygen, or nitrogen ions.

In 2021, the newest generation of the Helios Hydra DualBeam became compatible with AutoTEM 5 Software for fully automated sample preparation using various ion species.

Technological Advances Heralded by the Helios Hydra

There are two main advantages, the first of these being the ability to be able to use ultra-low voltage ions for the final polishing steps, and the second critical advancement for TEM sample preparation is the ability to use the fully automated sample preparation process in AutoTEM 5 with the Helios Hydra.

Initially, the Helios Hydra gave users the ability to switch gas species to change the ions and to tailor their ion species to their sample.

With the Helios 5 launch at the end of 2020, the user then had the ability to use accelerating voltages down to 500 volts for any of those ion species. For users, this meant that they could achieve near-to-no-damage sample preparation.

Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

The Helios 5 Laser and the Future of TEM Sample Preparation

With the Helios 5 Laser PFIB, Thermo Fisher Scientific expanded its range of TEM sample preparation techniques even further. This is because laser is a real advantage when it comes to deeper sectioning.

By utilizing the laser, the user is able to cut much larger areas that provide a better idea of the general microstructure of the sample. This is performed quickly with very little damage.

The Impact of Things Getting Smaller

Details of the sample material and the fine scale details are now more important than ever. Everything is getting smaller and so research can no longer be optically conducted anymore. There is, therefore, a push towards smaller feature sizes, which is driving the need for better microscopes - and better FIBs for making the samples you need to look at.

The area of energy - batteries, for example – is also becoming of increased interest. Using the FIB and all our characterization tools to understand what is going on inside a battery is becoming a vital part of the process. That, in particular, is where some of the cryo methods are becoming increasingly important.

I think the addition of the cryo capability to FIB is significant. This used to be the case for biology: cryo FIB and making cryo sections for biology became one of the most important techniques. I believe that, in the future, we are going to see a lot more of that with materials.

Francis Morrissey, Senior Account Manager at Thermo Fisher Scientific

Conclusion

Thermo Fisher Scientific is celebrating over 30 years of TEM sample preparation. Today, FIB sample prep has evolved into a fully automated, fast, and repeatable process. Thermo Fisher Scientific celebrates the scientists who use these market-leading systems and are committed to receiving feedback that fuels innovation.

Thermo Fisher Scientific is also committed to continuing to serve science and innovation, constantly advancing its instrument portfolio so that its customers have the freedom to be bolder and more innovative.

About David Foord

David Foord is a Director of Marketing within the Material Science business unit. In this capacity he is globally responsible for overseeing all aspects of Thermo Fishers TEM products in the Material Science market.

David has been at FEI/Thermo Fisher Scientific since 2000 fulfilling a variety of roles in applications, technical support, marketing and sales but always focusing on finding and providing the right solutions to FEI’s customers.

David has a PhD in Materials Science from the University of Cambridge UK.

About Francis Morrissey

Francis Morrissey is Senior Sales Account Manager for Life Science products in UK. In this capacity he is responsible for sales of TEM, SEM, FIB & DualBeam systems to the Life Science community.

Francis has been at FEI/Thermo Fisher Scientific since 1998 undertaking a variety of roles in applications, technical support, marketing and sales across Materials Science, Semi-Conductor and Life Science, with a keen interest in technology and it’s application to customers needs.

Francis has a PhD in Physics from the University of Bristol, UK.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Materials & Structural Analysis.

For more information on this source, please visit Thermo Fisher Scientific – Materials & Structural Analysis.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.