Henry Ford once remarked, “Any customer can have a car painted any colour that he wants, so long as it is black.” The quote reflects his focus on efficiency and cost control during the Model T era. Today, however, automotive body paint is a far more complex process.

Image Credit: Love Solutions/Shutterstock.com

Modern multi-layer coatings must not only provide durability and protection but also meet increasingly demanding aesthetic standards—a challenging combination to deliver.

In this context, Kiren Kang, Business Development Manager EMEA (Electron Microscopy/XPS) at Thermo Fisher Scientific, highlights how laser ablation provides a highly accurate and efficient method for cross-sectioning automotive paints.

Automotive coatings are designed to serve two main purposes: protecting the vehicle body from corrosion and delivering visual appeal. Meeting these goals requires the careful formulation and application of multi-layered coatings, with each layer serving a distinct function.

These systems often include five or more individual layers, each contributing to the performance and appearance of the final finish. A pre-treatment layer followed by an electrodeposition layer establishes the foundation of the coating system, enhancing adhesion and delivering critical corrosion protection. These are then layered with primer, basecoat, and clearcoat applications, which collectively provide the desired color, long-term durability, and a glossy finish.

Because of their complexity and the need for rigorous quality control, automotive body coatings represent a major cost in vehicle production—one that can increase substantially when quality standards are not met.

To prevent issues such as corrosion, UV degradation, peeling, surface defects, and uneven thickness, automotive paints must undergo detailed microscopic analysis before production approval.

Assessing Automotive Paint Quality

Many common methods for analyzing coating samples come with limitations. One traditional approach involves embedding paint samples in polymer resin blocks, which are then mechanically polished in several stages to create a cross-section of the paint layers on a steel substrate. Although commonly applied, this method is labor-intensive and often fails to produce the ultra-smooth surfaces needed for high-resolution analysis.

Another widely used method is gallium-focused ion beam (FIB) milling, which employs a concentrated beam of gallium ions to accurately cut and shape cross-sections of a sample. While this technique excels in producing highly precise sections for in-depth imaging and structural analysis, it has limitations. Gallium FIB generally creates cross-sections only around 20 microns in width and depth—far too small for analyzing automotive paint layers, which frequently exceed 100 microns in thickness.

Even xenon plasma FIB, which is more capable of handling thicker sections, becomes increasingly time-consuming when producing high-quality cross-sections beyond a few hundred microns. This is due to the need for low-current polishing and the application of a protective coating beforehand.

For those analyzing automotive body paints, relying on a single method may not be sufficient. Traditionally, combining multiple techniques has required several instruments and significant time. Fortunately, it is now possible to optimize both sample preparation and analysis using a single integrated system.

Achieving Cleaner Cross Sections

First, consider the most effective method for sample preparation. Given the complex, multi-layered structure of automotive paints, femtosecond laser ablation offers clear advantages over traditional cross-sectioning and ion beam techniques.

Unlike conventional mechanical polishing, which involves embedding samples in resin and gradually grinding them down, femtosecond laser ablation enables direct, non-contact material removal. This approach produces cleaner, more precise cross-sections without the risk of mechanical damage. The laser’s highly localized action allows for selective layer removal while preserving the integrity of underlying structures.

What sets femtosecond lasers apart is their exceptional speed. They can cut through a variety of materials much faster than typical FIB systems, making it possible to generate large, high-quality cross-sections in under five minutes.

In most cases, the laser-milled surfaces are clean enough for direct imaging with scanning electron microscopy (SEM) and are also suitable for surface-sensitive techniques such as energy-dispersive spectroscopy (EDS).

Combining Capabilities

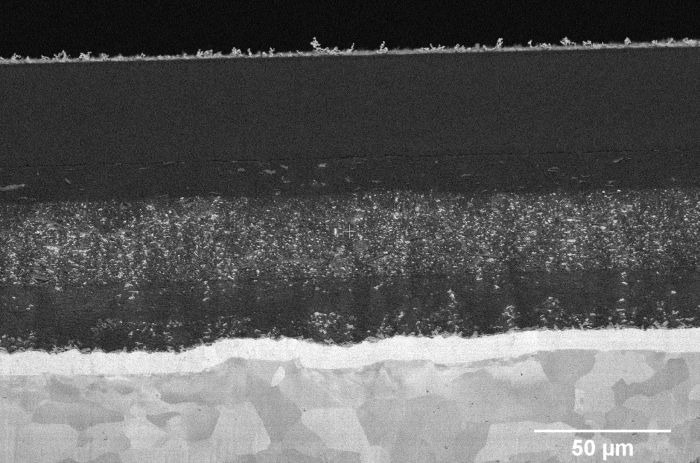

Automotive body paint analysis is further enhanced by the ability to perform both SEM and EDS on a single instrument. SEM plays a vital role by offering nanoscale imaging to reveal fine structural details of each coating layer, such as thickness, uniformity, and potential defects.

When paired with EDS, the system also delivers precise chemical analysis of the cross-section. This allows for verification of pigment distribution, detection of impurities, and confirmation that paint formulations meet required specifications.

These insights are especially valuable in quality control, helping manufacturers ensure that each layer (whether it’s a corrosion-resistant primer, metallic basecoat, or protective clear coat) contains the appropriate materials.

The Helios 5 Laser Plasma FIB from Thermo Fisher Scientific is engineered to overcome the limitations of traditional sample preparation methods by integrating multiple capabilities into a single instrument. By combining femtosecond laser ablation with FIB milling, it enables highly precise sample preparation at speeds up to 15,000 times faster than FIB alone.

With integrated SEM and EDS functionalities, the Helios 5 Laser Plasma FIB supports both structural and chemical analysis within one streamlined system. This all-in-one solution, combining laser ablation, plasma FIB, SEM, and EDS, equips manufacturers with a powerful tool for comprehensive evaluation of automotive body coatings.

SEM backscattered electron image of an automotive body coating cross-section. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

This integrated approach not only improves quality control and long-term coating performance but also reduces production downtime and material waste, making it an essential asset for today’s automotive industry.

Creating automotive body paints involves far more than choosing the right color. Achieving the optimal balance between appearance and performance demands careful formulation, rigorous testing, and detailed material analysis. By advancing preparation and evaluation methods, manufacturers can identify problems earlier, reduce inefficiencies, and ensure every layer performs as intended.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Electron Microscopy Solutions.

For more information on this source, please visit Thermo Fisher Scientific – Electron Microscopy Solutions.