Stainless steel’s chemical composition significantly impacts its specific properties, affecting its cost, performance, and lifespan. A comprehensive understanding of this composition and the key factors affecting it is vital when selecting the best option for a given application.

Image Credit: Evident Corporation

This article outlines seven key considerations when selecting stainless steel for a specific application, with practical examples and grade recommendations to inform the selection of stainless steel that meets an application’s needs.

Ensuring the Steel Provides Sufficient Resistance

One of stainless steel's core traits is its resistance to environmental factors. Corrosion resistance is vital for applications where the steel is exposed to chlorides, acids, or harsh marine and industrial conditions. It is also important to factor in resistance to both high and low temperatures for extreme environments.

Corrosion Resistance

Stainless steel grades 316, 316L, and 904L are ideal for marine environments due to their resistance to chloride corrosion and pitting. Grade 2205 duplex stainless steel is regularly used in industrial settings due to its enhanced corrosion resistance and strength.

High-Temperature Applications

Heat-resistant stainless steel grades, such as 310, S30815, and 446, are widely employed in heat exchangers and furnace parts.

Cryogenic Environments

Low-temperature stainless steel grades, including 304LN, 316, and 904L, retain their strength and toughness in extreme cold, making them ideally suited for use in cryogenic piping and LNG storage tanks.

The Importance of Formability

Formability determines the ease with which the steel can be shaped without cracking or losing its structural integrity.

Easily Formable Grades

Due to their exceptional formability, stainless steel grades 304, 316, and 430 are routinely used in the manufacture of kitchen sinks, cookware, and intricate architectural designs.

Special Applications

Stainless steel grades 2205 and 3CR12 are good options for higher corrosion resistance and formability applications.

Machining Requirements

Stainless steel's machinability varies according to its grade and composition. Work hardening during machining can pose challenges, but certain grades of stainless steel, such as 303 or 416, include sulfur to improve machinability.

Easy-to-Machine Grades

Stainless steel grades 303 and 416 are well suited for the production of machined components, including gears, screws, and fasteners. These grades offer a balance between acceptable corrosion resistance and machinability.

Balanced Machinability and Resistance

Stainless steel grade 3CR12 works well where wear resistance and machinability are equally important, such as in conveyor belts and mining components.

Welding Requirements

Welding stainless steel introduces risks such as cracking and corrosion if an incorrect grade is used.

Suitability for Welding

Stainless steel grades 304L and 316L are commonly used for food-grade equipment, including tanks and piping. This is primarily due to their low carbon content, which minimizes the risk of intergranular corrosion at weld joints.

Specialized Welding

Stainless steel grade 347 (stabilized with niobium) offers excellent resistance to stress corrosion cracking and high weldability, making it suited for chemical processing plants.

Heat Treatment Requirements

Heat treatment is a key consideration for certain applications due to its potential to alter stainless steel's mechanical properties.

Hardenable Grades

Stainless steel grades 440C and 17-4PH are widely used in precision tools like cutting blades and surgical instruments due to their high hardness and wear resistance following heat treatment.

Non-Hardenable Grades

Austenitic grades such as 304 and 316 are preferred for decorative panels or cladding, as these grades maintain surface finish and strength without hardening.

Ensuring the Steel is Strong Enough

Selecting the correct strength of stainless steel is essential because this ensures safety without unnecessary weight or costs.

High-Strength Grades

Precipitation-hardening steels like 17-4PH and martensitic steels like 440C offer superior strength and durability for automotive and aerospace components.

Moderate Strength and Ductility

Stainless steel grades 316 and 304 are regularly used in structural applications such as bridges or handrails, where a balance of strength and flexibility is necessary.

Dual Strength and Corrosion Resistance

Due to their excellent strength and resistance to stress corrosion cracking, offshore platforms and chemical storage tanks often employ duplex grades such as 2205 and 2507.

Comparing Upfront and Lifetime Costs

Stainless steel’s cost-effectiveness depends on its suitability for the specific environment and application.

High Corrosion Resistance with Longevity

Stainless steel grades 316 or 2205 can have higher upfront costs, but they have reduced maintenance and replacement requirements over time. This makes them ideally suited for use in water treatment or desalination plants.

Cost-Effective Options

Indoor applications such as decorative railings and elevator panels can benefit from stainless steel grades 430 or 3CR12 due to their lower initial costs while continuing to meet performance requirements.

The table below provides examples of stainless steel grade composition and the effect of alloying elements.

Examples of stainless steel grade composition and the effect of alloying elements. Source: Evident Corporation

| Grade |

Chromium (Cr) |

Nickel (Ni) |

Carbon (C) |

Molybdenum (Mo) |

Manganese (Mn) |

Silicon (Si) |

Nitrogen (N) |

Other elements |

| Effect on stainless steel |

Improve oxidation resistance and hardenability |

Improve strength, hardness, & ductility |

Improve strength, hardness |

Improve hardness, high temperature strength, & corrosion resistance |

Improve strength and minimize deoxidation |

Improve strength, hardness & oxidation resistance |

Improve corrosion, pitting, & crevice resistance |

|

| 304 |

18.0–20.0% |

8.0–10.5% |

≤0.08% |

– |

≤2.0% |

≤0.75% |

– |

– |

| 316 |

16.0–18.0% |

10.0–14.0% |

≤ 0.08% |

2.0–3.0% |

≤ 2.0% |

≤ 0.75% |

– |

– |

| 310 |

24.0–26.0% |

19.0–22.0% |

≤0.25% |

– |

≤2.0% |

≤1.50% |

– |

– |

| 904L |

19.0–23.0% |

23.0–28.0% |

≤0.02% |

4.0–5.0% |

≤2.0% |

≤1.00% |

– |

Copper (1.0–2.0%) |

| 2205 |

21.0–23.0% |

4.5–6.5% |

≤0.03% |

2.5–3.5% |

≤2.0% |

≤1.00% |

0.08–0.20% |

– |

| 3CR12 |

10.5–12.5% |

≤1.5% |

≤0.03% |

≤0.6% |

≤1.5% |

≤1.00% |

– |

Phosphorus (≤0.04%), Sulphur (≤0.015%) |

| 17-4PH |

15.0–17.5% |

3.0–5.0% |

≤0.07% |

≤0.50% |

≤1.0% |

≤0.50% |

– |

Copper (3.0–5.0%), Niobium (≤0.45%) |

| 303 |

17.0–19.0% |

8.0–10.0% |

≤0.15% |

– |

≤2.0% |

≤1.00% |

– |

Sulphur (0.15–0.35%) |

| 416 |

12.0–14.0% |

≤1.5% |

≤0.15% |

– |

≤ 1.25% |

≤1.00% |

– |

Sulphur (0.15–0.35%) |

| 347 |

17.0–19.0% |

9.0–13.0% |

≤0.08% |

– |

≤2.0% |

≤0.75% |

– |

Niobium (≤1.0%) |

| 430 |

16.0–18.0% |

– |

≤0.12% |

– |

≤1.0% |

≤1.00% |

– |

– |

| S30815 |

24.0–26.0% |

19.0–21.0% |

≤0.10% |

0.20–0.60% |

≤2.0% |

≤1.50% |

0.08–0.20% |

– |

Simplifying the Choice with Accurate Grade Identification

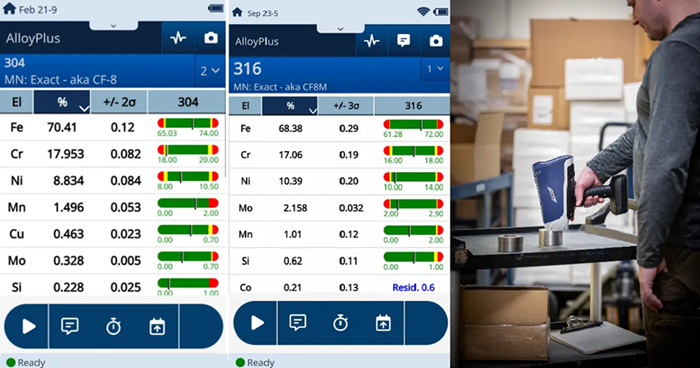

Results of steel grade testing using the Vanta portable X-ray fluorescence (pXRF) analyzer. Image Credit: Evident Corporation

Selecting the most appropriate stainless steel grade for a given application can be complex, but this decision is critical.

Maintaining complete control over the materials purchased is key to reinforcing product reliability and performance, preventing potentially expensive errors, and ensuring compliance with relevant quality standards.

Vanta handheld XRF analyzers provide instant grade match messages in real-time with familiar trade or grade names, reducing the training curve and increasing efficiency. Image Credit: Evident Corporation

Evident Scientific's Vanta® portable X-ray fluorescence (pXRF) analyzer is an invaluable tool for maintaining complete control over the materials used.

This robust instrument delivers precise, non-destructive stainless steel grade identification and composition analysis. Integrating powerful pXRF technology into application workflows can help streamline the material selection process and improve confidence in every stainless steel purchase.

Acknowledgments

Produced from materials originally authored by Vladimir Vermus from Evident Scientific.

This information has been sourced, reviewed and adapted from materials provided by Evident Corporation.

For more information on this source, please visit Evident Corporation.