Sponsored by Specac LtdReviewed by Maria OsipovaJun 20 2025

Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS) is an extremely powerful analytical technique suitable for studying powdered materials and materials with rough surfaces.

Key considerations for sample prep for DRIFTS experiment

Video Credit: Specac Ltd

DRIFTS is routinely used in quality control applications, materials characterization, and catalytic studies in industrial and research settings. However, optimal instrument setup and sample preparation are key to acquiring the most reliable results and guaranteeing robust data interpretation.

This article outlines several best practices designed to support researchers, R&D professionals, and quality control managers who work with DRIFTS equipment.

Understanding DRIFTS

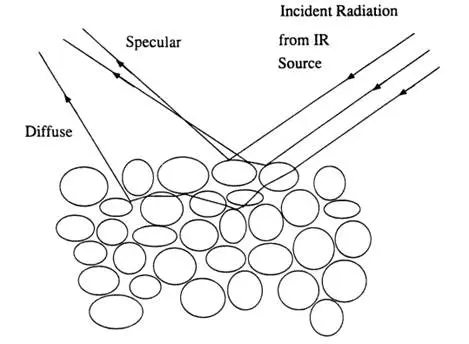

While conventional Fourier Transform Infrared (FTIR) spectroscopy is dependent on transmission measurements, DRIFTS can capture diffusely scattered infrared radiation from powdered samples due to specular reflection (Figure 1).

This makes DRIFTS especially useful when working with materials that are difficult to analyze with traditional transmission-based setups. Its high sensitivity to surface interactions also makes it ideally suited to studying catalytic reactions, adsorption processes, and chemically modified solid surfaces.

DRIFTS requires no optical contact with the sample, meaning that it is possible to maintain gas flow through a sample during data acquisition. This is key to the real-time in situ monitoring of gas-surface interactions, like those encountered in investigations into catalytic processes.

DRIFTS-based analysis also benefits from non-destructive analysis and minimal sample preparation requirements. Diffuse reflectance is a suitable, practical alternative if a sample is not reflective and unsuitable for analysis via traditional transmission FTIR spectroscopy.

Figure 1. Schematic illustrating the distinction between diffuse and specular reflections for a powdered sample. Image Credit: Specac Ltd

The Kubelka–Munk (KM) Transformation in DRIFTS Analysis

The Kubelka–Munk (KM) transformation can be used to quantitatively analyze DRIFTS spectra. KM transformation is useful here, because it provides a mathematical model of diffuse reflectance properties based on certain key assumptions.2,3

Kubelka and Munk’s equation helps define the relationship between diffuse reflectance and analyte concentration in terms of the sample’s absorption and scattering coefficients.2 However, the model’s inherent practical limitations mean diffuse reflectance must always be measured relative to a reference sample.3

The concentration of surface species can be measured via the application of the KM transformation, simplifying the interpretation of complex spectral data. This equation proves beneficial in various fields where analyzing molecular interactions on solid surfaces is essential, including catalysis, pharmaceuticals, and materials science.

In catalysis, for example, the KM transformation supports researchers’ exploration of active sites and adsorbed species on materials such as zeolites and metal oxides. Applying the KM transformation to DRIFTS data generates more reliable, clearer insights and enables more straightforward monitoring of chemical reactions.

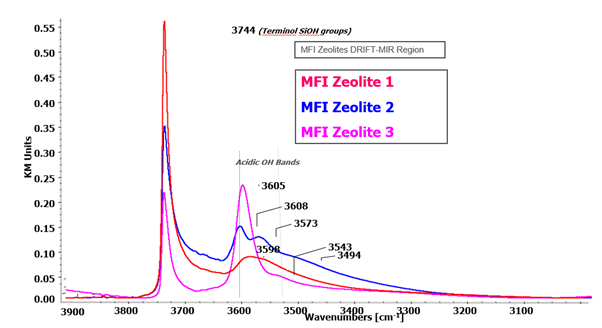

Figure 2 features a typical result obtainable using Harrick’s Praying Mantis™ Diffuse Reflection Accessory.

The KM units on the y-axis show that the KM transformation has already been applied to the raw reflectance data shown, making this data more suitable for quantitative analysis.

The x-axis represents wavenumber (in cm−1). Certain vibrational bands of surface hydroxyl groups are highlighted due to their relevance to catalysis applications. Monitoring these signals in real time to follow catalytic reactions would be possible.

Figure 2. Example data obtained from a DRIFTS experiment that examined three zeolite samples, after KM transformation. Image Credit: Specac Ltd

Best Practices for Sample Preparation

1. Use an Appropriate Non-Absorbing Matrix

The sample should be diluted in a non-absorbing matrix or reference material in order to improve signal quality and minimize spectral artifacts. Typical matrix materials include:

- KBr or KCl, where mid-IR measurements are required

- Diamond powder, where applications require extreme robustness

2. Optimize Particle Size

Improving reproducibility by using finer particle sizes to ensure a uniform scattering environment is possible. Particle size should be <40 µm, ideally within the 5–10 µm range. It is possible to achieve ideal sample characteristics by:

- Employing a mortar and pestle or a Wig-L-Bug grinder to achieve the desired consistency

- Avoiding excessive grinding, because this can negatively affect sample properties and introduce data artifacts

3. Manage Moisture Content

The presence of moisture can result in unwanted spectral interference. This can be prevented by:

- Oven-drying the reference material prior to use

- Storing samples in a desiccator before measurement

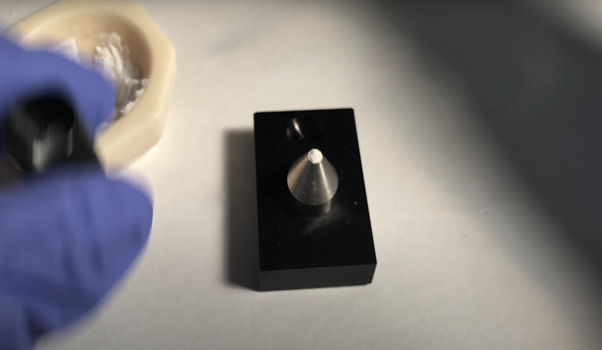

4. Ensure Consistent Packing Density

Maintaining a consistent sample packing density in the sample holder is essential to ensure reproducibility (Figure 3). Appropriate packing can be ensured by:

- Removing air pockets by gently tapping the sample cup

- Avoiding the use of excessive pressure, because this can lead to specular reflection artifacts

5. Verify the Instrument’s Optical Alignment

Correct optical alignment is essential if high-quality DRIFTS spectra are to be acquired. Misalignment can result in spectral distortions, signal loss, or unwanted artifacts. Maintaining consistency and reliable measurement performance can be ensured by:

- Routinely checking the alignment of optical components and mirrors in the DRIFTS accessory

- Confirming that incident light is correctly focused on the sample

- Following all manufacturer recommendations around alignment and calibration procedures

Figure 3. Image showing a correctly packed sample in the Microsample Cup of the Harrick Praying Mantis Diffuse Reflection Accessory. Image Credit: Specac Ltd

Step-by-Step Sample Preparation and Analysis

Samples should be prepared according to the following procedure.

- Begin by grinding the sample with a Wig-L-Bug mill or mortar and pestle in order to achieve a fine, uniform particle size.

- Dry the reference material (for example, KBr) in an oven and store it in a desiccator to keep it moisture-free.

- Dilute the sample in the reference material, aiming for a 2–15% sample concentration in the reference matrix, and ensure thorough blending to achieve a uniform mixture. This concentration will depend on how strongly the sample is absorbed.

- Load the Praying Mantis™ sample cup with the dry reference material and flatten the surface to prepare this for data acquisition. Record a background spectrum once this has been done.

- Empty the reference material from the sample cup before loading the sample mix. The height of the sample stage should be adjusted and the surface leveled to complete the preparation process. The sample spectrum can be acquired after loading the sample cup into the Praying Mantis™ Diffuse Reflection Accessory (Figure 4).

Figure 4. Loading the Sample Cup, containing a properly prepared sample, into the Praying Mantis Diffuse Reflection Accessory. Image Credit: Specac Ltd

Instrument Optimization for Reliable Spectra

The instrument should be optimized prior to acquiring a spectrum.

1. Selecting the Right Optical Accessory

A well-designed DRIFTS accessory improves diffuse signal collection while simultaneously minimizing specular reflectance.

For example, Harrick’s Praying Mantis™ Diffuse Reflection Accessory improves spectral quality by employing an ellipsoidal mirror design in order to ensure that only diffusely scattered light is collected.

The Praying Mantis™ range of accessories also features optional reaction chambers and temperature controllers, making it ideally suited to the analysis of samples across a wide range of pressures and at high temperatures.

2. Optimizing Background and Sample Measurements

A series of simple steps can help to optimize the background spectrum and improve measurement accuracy.

- Before making sample measurements, it is important to collect a background spectrum using a well-packed, non-absorbing reference matrix.

- Maximize the collected signal by positioning samples at the optimal focal point of the optical system.

- Utilize an appropriate resolution (generally 4 cm−1) and signal averaging in order to improve signal-to-noise ratio.

3. Detector Considerations

A liquid nitrogen-cooled mercury–cadmium–telluride (MCT) detector offers superior sensitivity for mid-IR DRIFTS, while a standard deuterated l-alanine-doped triglycine sulphate (DTGS) detector may be sufficient for broader applications.

How to Avoid Common Spectral Artefacts

It is possible to avoid common spectral artifacts by following a series of simple steps.

1. Minimize Specular Reflection

Specular reflection can distort DRIFTS spectra, particularly when working with highly absorbing materials. This can be mitigated through the use of an off-axis collection setup or an accessory able to deflect specular components away from the detector.

It is also essential to ensure uniform sample distribution to reduce surface gloss.

2. Avoid Reststrahlen Bands

There is a risk of highly absorbing materials producing distorted bands known as reststrahlen bands (‘residual rays’ in German). This is especially prevalent in the mid-IR range. These signals can be suppressed by:

- Increasing the sample’s dilution ratio in the reference material, should reststrahlen bands be observed

- Leveraging spectral subtraction techniques to isolate the genuine sample signal

3. Factor in Thermal Effects in High-Temperature Studies

When working with in situ DRIFTS studies that involve temperature variation, it is advisable to adjust experimental parameters accordingly. This may include:

- Compensating for the effect of expansion and contraction by precisely controlling sample height, for example, to keep the sample at the optimal focal point

- Using appropriate shielding to prevent sample self-emission when working with high temperatures

- Ensuring that background and sample spectra are matched at identical temperatures

Enhancing DRIFTS Applications in Research and Industry

Different DRIFTS applications require specific considerations, depending on the industry or research area in question.

1. Catalysis and Surface Chemistry

DRIFTS is widely used in the petrochemical industry to study heterogeneous catalysts for refining processes.

Here, DRIFTS facilitates the real-time monitoring of catalyst surfaces under typically high-temperature and high-pressure conditions, allowing researchers to optimize chemical processes such as hydrocracking and fluid catalytic cracking (FCC).

DRIFTS is employed in the pharmaceutical industry to monitor solid-state reactions and characterize the interaction of active pharmaceutical ingredients (APIs) with excipients-a key factor in drug stability and the development of effective formulation strategies.

2. Quality Control and Material Characterization

DRIFTS is used in polymer science to evaluate surface modifications and treatments, for example, plasma treatments for improved adhesion.

It is applied in fertilizer and soil analysis in agriculture to ensure optimal nutrient content.

DRIFTS is employed in the ceramics sector to evaluate material composition and structural integrity during production. The ceramics industry works with a wide range of inorganic, non-metallic materials, ranging from clay-based products like porcelain or tiles to the advanced ceramics employed in biomedical implants, aerospace applications, and electronics.

3. In Situ and Operando Studies

DRIFTS’ non-destructive nature makes it ideally suited to the real-time analysis of chemical processes, especially in high-temperature and high-pressure environments. For example, in terms of heterogeneous catalysis, the study of adsorption–desorption mechanisms in catalytic converters is key to controlling vehicle emissions.

Conclusion

A well-optimized DRIFTS setup is central to the acquisition of reliable, reproducible spectra.

Regular instrument calibration, awareness of correct sample preparation, and strategies to avoid potential artifacts can assure high-quality results.

Following best practices in these areas will allow researchers, R&D professionals, and quality control managers to comprehensively leverage DRIFTS as a powerful technique for in-depth process monitoring and materials analysis.

References and Further Reading

- M. B. Mitchell,(1993). Structure-Property Relations in Polymers. Washington, DC: Google Books. (online) Available at: https://books.google.co.in/books/about/Structure_Property_Relations_in_Polymers.html?id=bUMpAAAAYAAJ&source=kp_book_description&redir_esc=y (Accessed 17 Jun. 2025)

- Mirabella, F. (1998). Modern Techniques in Applied Molecular Spectroscopy. (online) Academia. Available at: https://www.academia.edu/110571091/Modern_Techniques_in_Applied_Molecular_Spectroscopy (Accessed 17 Jun. 2025).

- Jinda Sirita, Sukon Phanichphant and Meunier, F.C. (2007). Quantitative Analysis of Adsorbate Concentrations by Diffuse Reflectance FT-IR. Analytical Chemistry, 79(10), pp.3912–3918. https://doi.org/10.1021/ac0702802.

This information has been sourced, reviewed and adapted from materials provided by Specac Ltd.

For more information on this source, please visit Specac Ltd.