Plastics are widely used across industries thanks to their low corrosiveness, slow decomposition, and malleability. However, these same properties that make plastics so versatile also contribute to growing environmental concerns. Their persistence in ecosystems, evident in ocean pollution and the presence of microplastics in food and water, underscores the challenges they pose for waste management.

For example, 260 Mt of plastics is produced annually, with 38 % of this used for packaging. This packaging typically reaches its final destination in the waste after it has fulfilled its function, with plastic packaging accounting for 76 % of the disposed plastic in the European Union.1,2

Made from non-renewable petrochemicals, recycling plastic waste is a key strategy to reduce global reliance on fossil fuels and minimize plastic waste.

Plastic Recycling with Twin-Screw Extruders

A common recycling method involves melting and re-extruding plastics. Single-screw extruders are used initially to reshape shredded waste, while co-rotating twin-screw extruders in the second stage blend in colourants, fillers and other additives.

Novel twin-screw extruder solutions are also commercially available, combining two twin-screw extruders to facilitate enhanced degassing and odor removal.

Down-scaled extruders that save both material and time are valuable in the investigation of recycling solutions and in the development of additives. Thermo Scientific™ offers lab-scale and pilot-scale twin-screw extruders with throughputs ranging from 200 g per hour to 30 kg per hour.

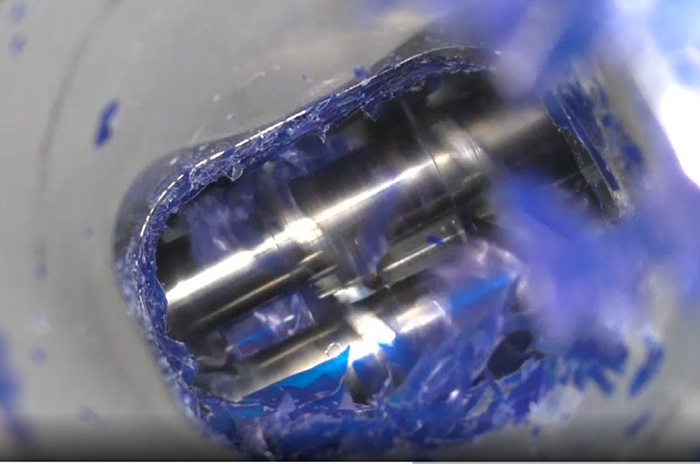

Figure 1. Thermo Scientific Process 16 twin-screw compounder and twin-screw feeder for foil shred recycling. Image Credit: Thermo Fisher Scientific – Materials Characterization

Co-rotating twin screw extruders provide many advantages for plastic recycling applications. These include:

- Delivers excellent dispersive and distributive mixing to compensate for variations in input material properties

- Enables efficient degassing through continuous surface renewal of the melt, providing a large surface area for the removal of odors and volatile contaminants

- Optional melt stripping using water, nitrogen, or carbon dioxide to further enhance degassing performance

Thermo Scientific Process 16: The Pilot Extruder for Foil Shred Recycling

It is usually easy to feed high-density regrind into the extruder, but fluffy foil shred and low bulk density fibers tend to cause issues. As a result, it is normally faster to shred material to further reduce its size and compaction.

The Process 16 Twin-Screw Extruder from Thermo Scientific eases the feeding of larger foil shreds thanks to its especially wide feed throat. This also prevents blockage and allows for additional stuffer feeders. Special wide throat screw elements in the feed section enhance the rapid conveying of shreds into the extruder barrel.

Figure 2. Large primary feed port of Thermo Scientific Process 16 twin-screw extruder with wide throat feed screw elements ensures uptake of larger foil shreds. Image Credit: Thermo Fisher Scientific – Materials Characterization

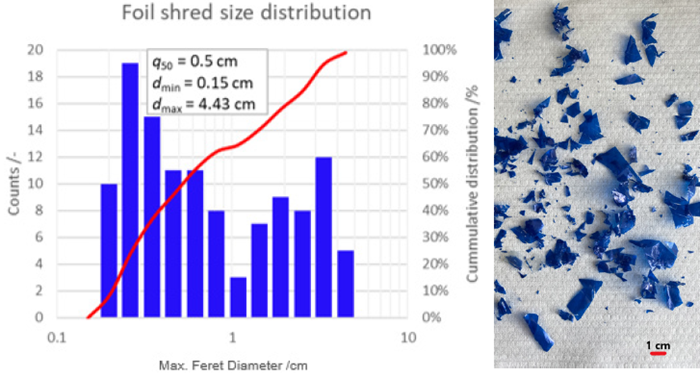

Dosage of foil shreds into the extruder is enabled with an agitated twin-screw feeder fitted with spiral screws and offering an adjustable screw speed. This feeder continuously conveys foil shreds with a broad size distribution (Figure 3) into the extruder.

Figure 3. Maximum Feret length distribution (left) of foil shreds obtained by analysis of the displayed image (right). Image Credit: Thermo Fisher Scientific – Materials Characterization

Stickiness caused by electrostatic charge is another common challenge associated with the handling of plastic foil shreds. Foil shreds can potentially attach to surfaces such as the feeder outlet and the feed funnel, with larger amounts often piling up and causing a blockage.

Placing an ionisator at the feeder outlet (Figure 4) discharges these shreds and helps to maximize the feeder output.

Figure 4. Twin-screw feeder with Ionisator at the outlet tube prevents feed funnel blockage by electrostatically charged foil shreds. Image Credit: Thermo Fisher Scientific – Materials Characterization

References and Further Reading

- Hundertmark, T., et al. (2018). How plastics waste recycling could transform the chemical industry. (online) McKinsey & Company. Available at: https://www.mckinsey.com/industries/chemicals/our-insights/how-plastics-waste-recycling-could-transform-the-chemical-industry.

- Sati Manrich and Santos, A. (2009). Plastic recycling. ResearchGate, (online) pp.1–99. Available at: https://www.researchgate.net/publication/324156265_Plastic_recycling (Accessed 13 Sep. 2025).

Acknowledgments

Produced from materials originally authored by Annika Völp from Thermo Scientific.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Materials Characterization.

For more information on this source, please visit Thermo Fisher Scientific – Materials Characterization.